Multi-layered sleeve windowing milling shoe

A multi-layer casing and shoe grinding technology, which is applied in wellbore/well components, earth-moving drilling, etc., can solve the problem of sidetracking without technical casing, increasing difficulty in window formation, and low window opening efficiency and success rate. To meet the window opening standards and other issues, to achieve the effect of improving the milling speed and ensuring the safety of well control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

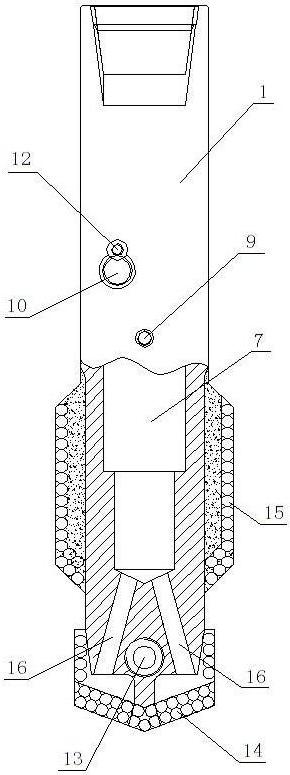

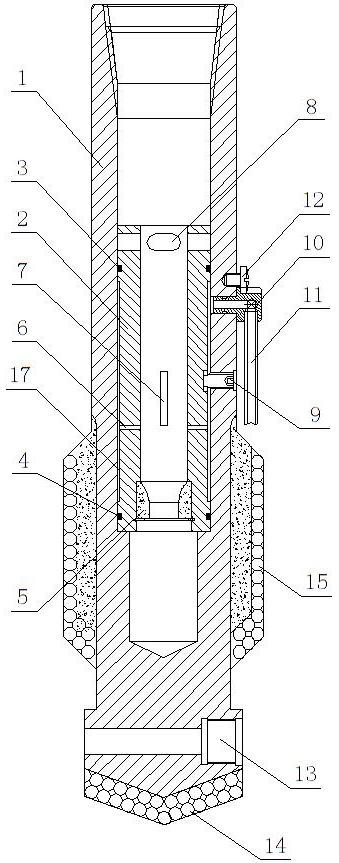

[0014] The multi-layer casing window grinding shoe of the present invention is composed of a grinding shoe matrix 1, a pressure transmission sleeve 2, a pressure transmission plug 10, a copper pipe 11, and a pilot grinding shoe 14. The upper part of the grinding shoe matrix 1 It is connected to the upper drilling tool by the drill pipe buckle. The mill shoe matrix 1 is hollow and has a shoulder at the lower end of the inner wall. Close fit, the middle part of the outer wall is provided with an annular groove and the inner wall of the shoe carcass 1 to form an annular gap 17, which is convenient for the fluid to pass through the pressure. Ring 3 and lower sealing ring 4 are sealed, and positioning pin 9 passes through the carcass 1 of the mill shoe to fix the outer wall of the pressure transmission sleeve 2 with the carcass 1 of the mill shoe. On the same circumference of the outer wall of the upper end of the pressure transmission sleeve 2, there are four pick-up and delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com