Plastic runway cleaning machine

A plastic runway and cleaning machine technology, applied in the field of cleaning machines, can solve the problem of no small automatic cleaning machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, this patent is described in further detail.

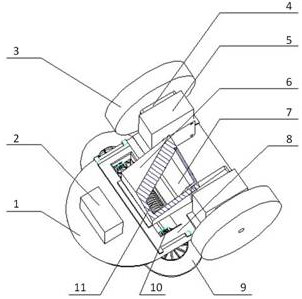

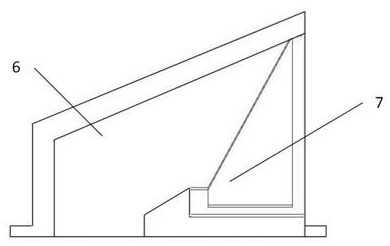

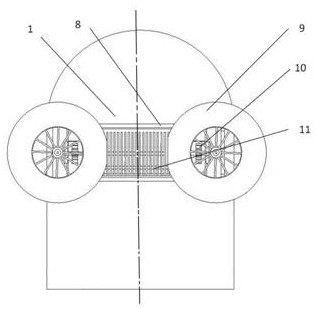

[0012] like figure 1 As shown, this patent consists of chassis (1), battery (2), wheels (3), drive motor (4), motor frame (5), outer dust collection box (6), inner dust collection box (7), lower Hanger (8), brush (9), friction wheel (10), brush roller (11), wherein the outer dust box (6) and the inner dust box (7) form the dust box, the lower hanger (8), hair brush (9), friction wheel (10), and hair brush roller (11) together form a cleaning and collecting system. The cleaning machine is driven forward by the driving motor (4) powered by the battery (2). During the forward process, the friction wheel (10) rubs against the ground, driving the brush (9) to rotate from the outside to the inside, and the brush roller (11) to rotate backward. , collect the garbage on the plastic runway that needs to be cleaned and get involved in the dust box connected to the cleaning and collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com