Intelligent forging and pressing device for steel manufacturing

A forging and intelligent technology, applied in the field of steel manufacturing, can solve problems such as difficult forging operations, lower surface temperature, and dangers, and achieve the effects of simple structure, improved use comfort, and reduced safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

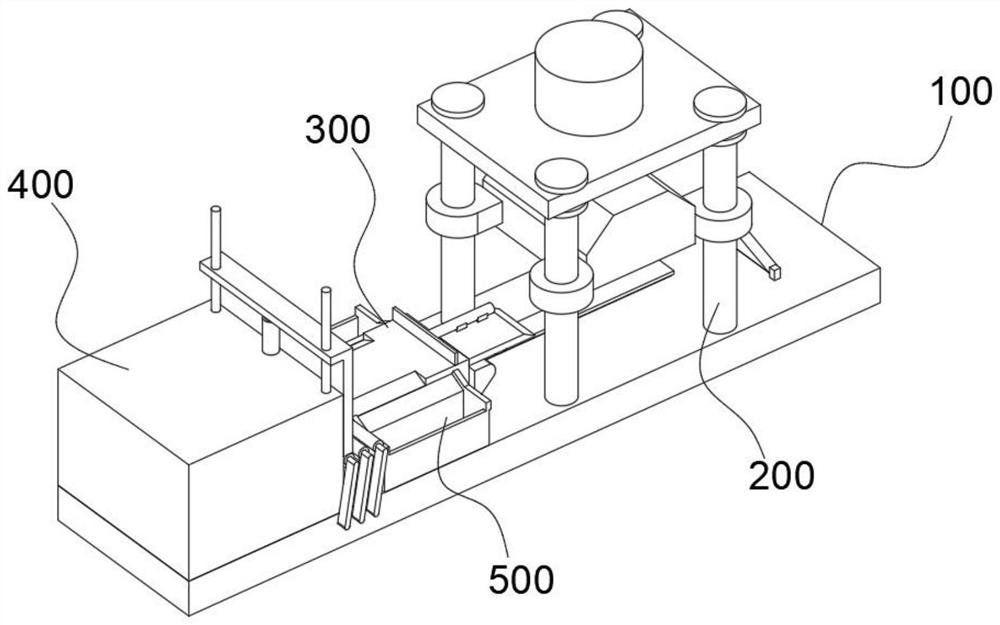

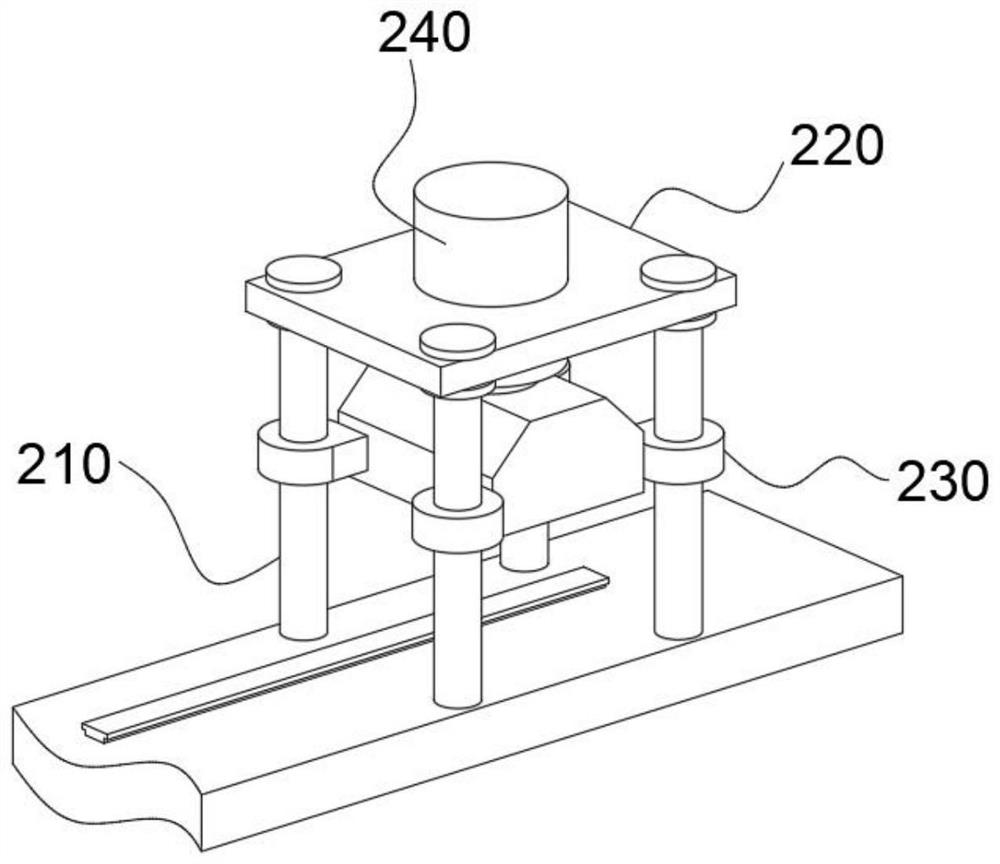

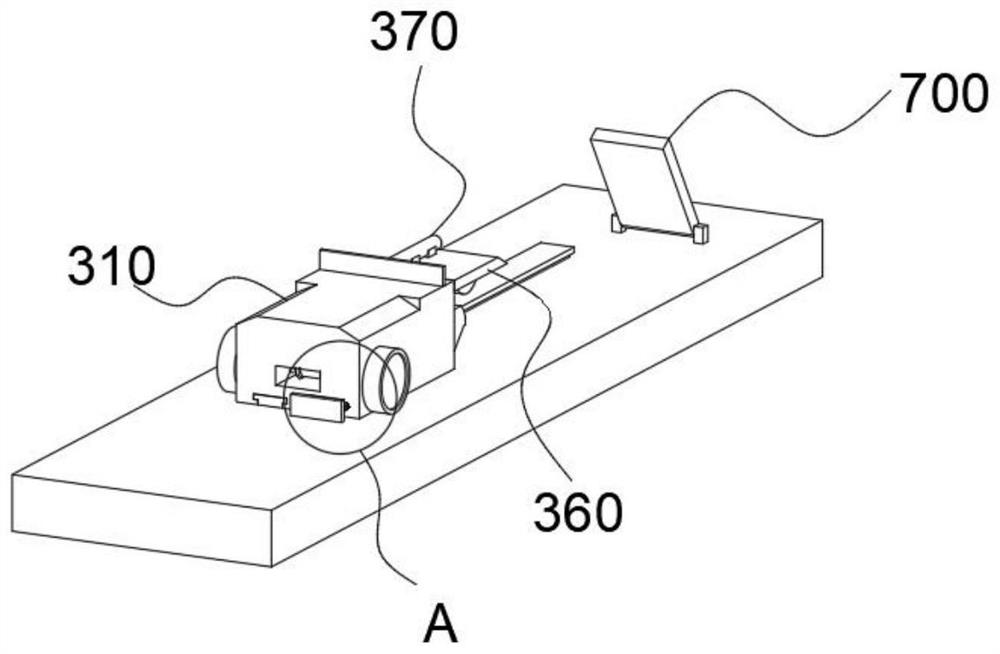

[0047] combine Figure 1-9 As shown, an intelligent forging device for steel manufacturing provided by the present invention includes a base plate 100 on which a forging module 200, a feeding module 300 and a calcining module 400 are arranged, and the forging module 200 includes a base plate 100 A plurality of guide rods 210 connected at the top, the guide rods 210 guide the die-casting plate 230, so that it can stably die-cast steel, and the top plate 220 connected between the plurality of guide rods 210, the top plate 220 plays a role in stabilizing the plurality of guide rods. The function of rod 210 is also to support hydraulic cylinder 240, and the die-casting plate 230 slidingly sleeved on the outside of a plurality of guide rods 210 and the hydraulic cylinder 240 connected between the top plate 220 and die-casting plate 230, the die-casting plate 230 is a metal material with high hardness, which is fully suitable for the forging of red-hot steel, and the hydraulic cylin...

Embodiment 2

[0056] combine Figure 1-2 As shown, on the basis of Embodiment 1, a plurality of guide rods 210 are arranged at equal intervals in a matrix, and two limit discs are sleeved on the outside of the guide rods 210, and the two limit discs are respectively Attached to the top and bottom of the top plate 220 , the limiting circular plate has the function of fixing the top plate 220 and improving the firmness of the top plate 220 installation.

Embodiment 3

[0058] combine figure 1 and Figure 9 As shown, in the above embodiment, two waste boxes 500 are installed on the top of the substrate 100, and the two waste boxes 500 are respectively located on the front and rear sides of the forging table 310, and the waste boxes 500 can be collected from the forging table 310 in a unified manner. falling debris.

[0059] The working principle and application process of the present invention: in the initial state, red-hot steel is placed on the forging table 310, and then the horizontal plate 360 is in an upright position. When the present invention is put into practical use, the hydraulic cylinder 240 drives the die-casting plate 230 to pair the steel Carry out forging, and after a certain period of time, start the biaxial motor 320, and the biaxial motor 320 drives the roller 330 to rotate, so that friction is generated between the roller 330 and the substrate 100, and then the forging table 310 moves to the direction of the calcining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com