Railway drainage ditch desilting device

A technology for dredging devices and drainage ditches, which is applied to water supply devices, waterway systems, buildings, etc., can solve problems such as the inapplicability of railway drainage ditches for sand cleaning operations, and achieve convenient centralized and harmless treatment, reduce environmental pollution, and eliminate hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

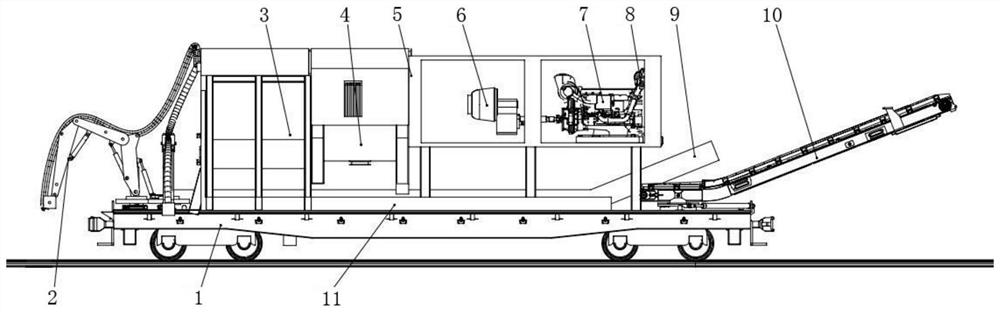

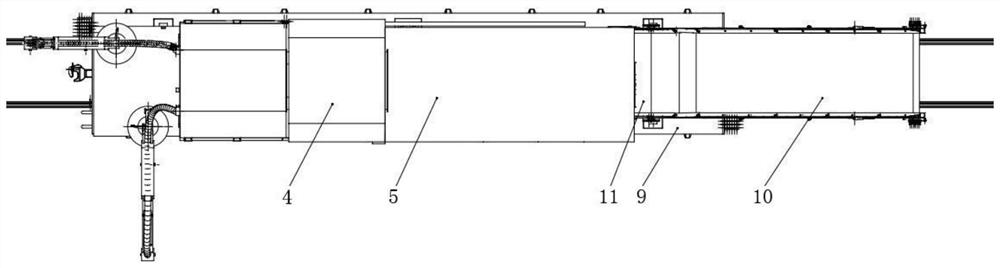

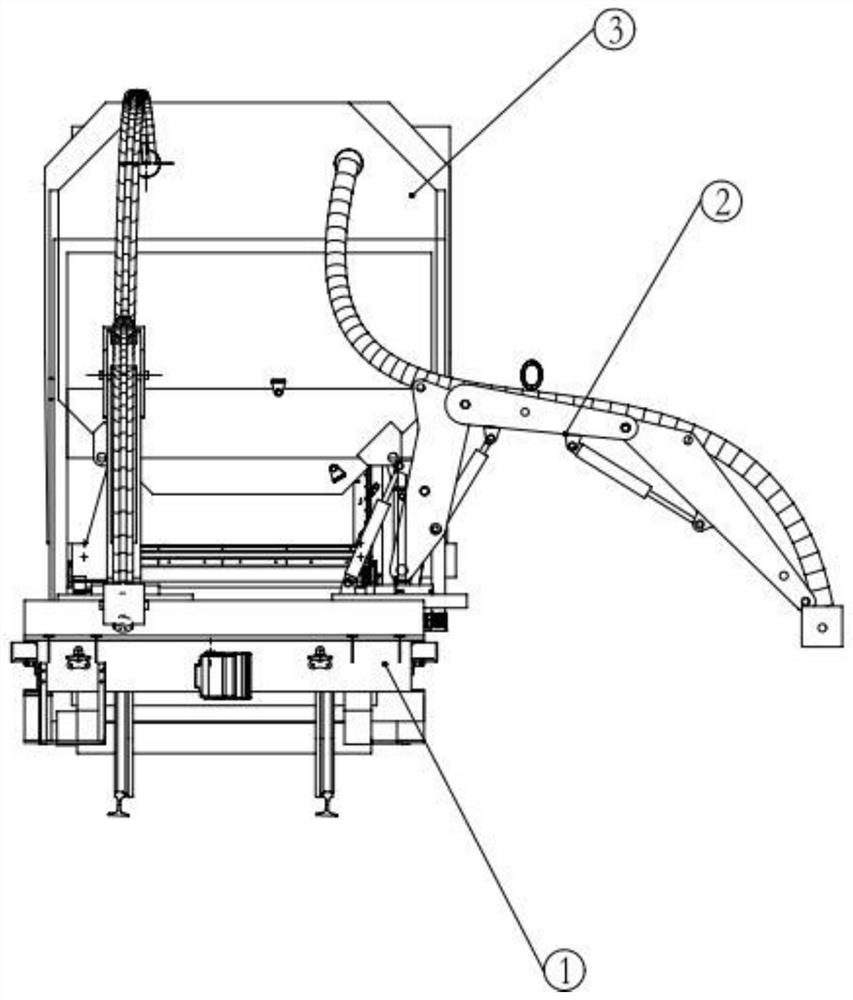

[0027] Combine below Figure 1-9 Describe in detail the preferred technical scheme of the railway drain dredging device:

[0028] A railway drainage ditch dredging device, comprising a flatbed car 1, a mechanical arm 2 is installed at the left end of the flatbed car 1, a rotating parabolic belt 10 is installed at the right end of the flatbed car 1, a suction pipe 12 is installed at the front end of the mechanical arm 2, and the mechanical arm 2 and the rotating parabolic belt 10 The overall installation frame 11 is installed on the flatbed car 1 in between, and the overall installation frame 11 is equipped with the coarse filter dust collector 3, the fine filter dust collector 4 and the power room 5 successively from left to right, the coarse filter dust collector 3 and the fine filter dust collector 4 Connected, the power room 5 is equipped with fan 6, engine 7 and radiator 8 successively from left to right. The suction pipe 12 is connected with the coarse filter dust collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com