Waterproof and oilproof agent as well as preparation method and application thereof

A water- and oil-repellent, deionized water technology, applied in coatings, paper coatings, paper, etc., can solve problems such as inability to directly recycle and reuse, hidden dangers to human health and safety, and difficulty in paper separation, achieving superior safety, environmental protection, and waterproofing. Improved oil-repellent effect, good waterproof and oil-repellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

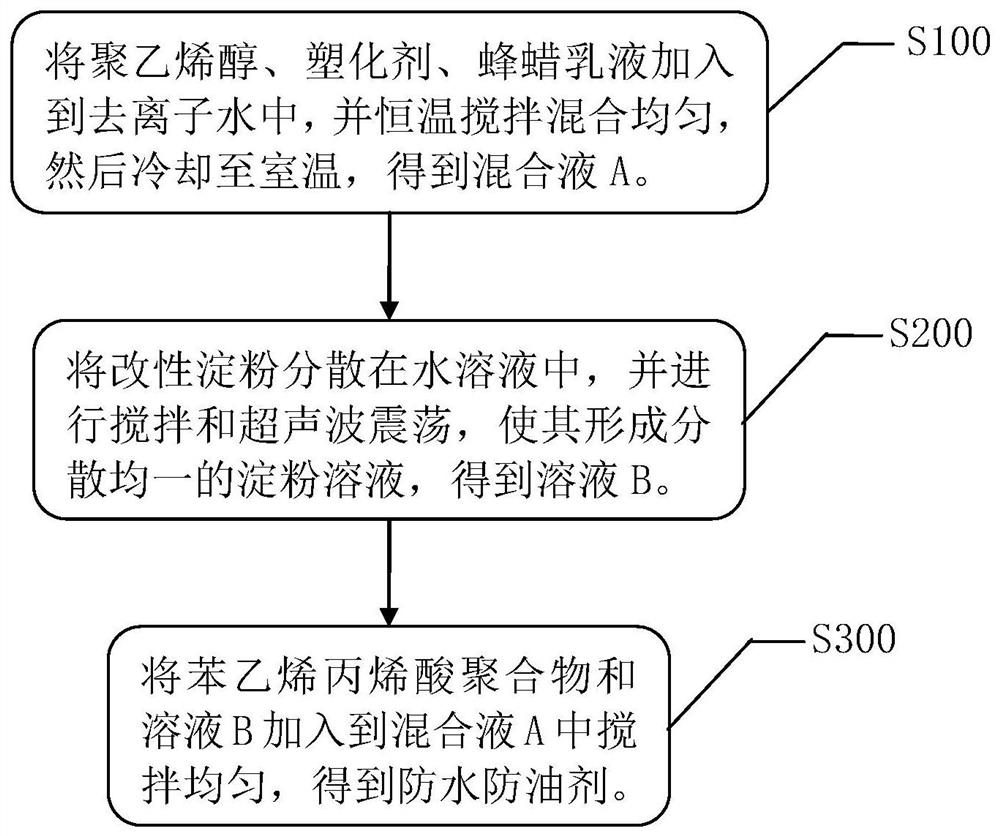

[0026] Such as figure 1 Shown, the preparation method of water and oil repellent of the present invention specifically comprises the following steps:

[0027] Step S100. Add polyvinyl alcohol, plasticizer, and beeswax emulsion into deionized water, and stir and mix uniformly at a constant temperature, and then cool to room temperature to obtain a mixed solution A; wherein, the uniform stirring and mixing at a constant temperature is specifically: at 70~ Stir and mix evenly in a constant temperature water bath under the condition of 95°C, and the time of the constant temperature water bath is preferably 60-90 minutes.

[0028] Step S200. Disperse the modified starch in the aqueous solution, and perform stirring and ultrasonic vibration to form a uniformly dispersed starch solution to obtain solution B; wherein, the stirring and ultrasonic vibration refer to mechanical stirring, and then placed in an ultrasonic Ultrasonic vibration in the cleaning agent, stirring for 0.5 to 1 h...

Embodiment 1

[0036] (1) Add 2.5% polyvinyl alcohol, 0.5% glycerin, and 5% beeswax emulsion into 60% deionized water, stir and mix evenly in a constant temperature water bath at 70°C for 60 minutes, and cool to room temperature to obtain a mixed solution A;

[0037] (2) Disperse the modified starch in the aqueous solution, stir it mechanically for 0.5 h, and then place it in an ultrasonic cleaning agent and oscillate it ultrasonically for 5 min to form a uniformly dispersed starch solution to obtain solution B;

[0038] (3) Add 30% and 2% solution B of styrene-acrylic acid polymer into the mixed solution A, and stir evenly at room temperature to obtain the water and oil repellent;

[0039] (4) Apply the waterproof and oil-repellent agent to the surface of food-grade base paper, dry it, and place it under constant temperature and humidity (temperature 23° C., humidity 50%) for 48 hours to obtain a water-based fluorine-free waterproof and oil-repellent coating.

[0040] (5) Using the T559 sta...

Embodiment 2

[0042] (1) Add 3.5% polyvinyl alcohol, 1% epoxidized soybean oil, and 7.5% beeswax emulsion into 45% deionized water, stir and mix evenly in a constant temperature water bath at 70°C for 80 minutes, and cool to room temperature to obtain a mixed solution A;

[0043] (2) Disperse the modified starch in the aqueous solution, stir it mechanically for 0.5 h, and then place it in an ultrasonic cleaning agent and oscillate ultrasonically for 15 min to form a uniformly dispersed starch solution to obtain solution B;

[0044] (3) Add 39% and 4% solution B of styrene-acrylic acid polymer into the mixed solution A, and stir evenly at room temperature to obtain the waterproof and oil-repellent agent;

[0045](4) Apply the waterproof and oil-repellent agent to the surface of food-grade base paper, dry it, and place it under constant temperature and humidity (temperature 23° C., humidity 50%) for 48 hours to obtain a water-based fluorine-free waterproof and oil-repellent coating.

[0046] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com