A dye modified peg and its application in acidic bright copper plating

A technology of dye and copper plating, which is applied in dye-modified PEG and its application in acidic bright copper plating, can solve the problems of pinholes and pitting, low upper limit temperature, etc., and avoid salting out and coagulation, Effect of increasing stability and improving deep plating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

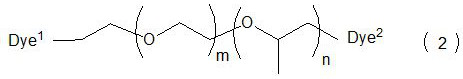

[0033] A dye-modified PEG is a phenolphthalein-modified EO / PO block copolymer (EO%=50%, average molecular weight 1000), and the structural formula is as follows:

[0034]

[0035] The synthesis method of the phenolphthalein-modified EO / PO block copolymer is as follows: take 0.318 g of phenolphthalein, and one end is esterified with p-toluenesulfonyl chloride. The EO / PO block copolymer (EO%=50%, average molecular weight 1000) 2 g, KI 0.200 g, anhydrous potassium carbonate 1.102 g were added to the reactor, 20 ml of anhydrous N,N-dimethylformamide was added, and the reaction was carried out at 80 degrees Celsius for 24 hours under nitrogen protection; cooled, filtered, and the filtrate was reduced. Concentrate under pressure to give an oil. The oil was purified by recrystallization from ether to give 1.585 g of product in 83% yield.

Embodiment 2

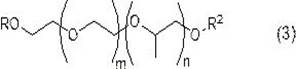

[0037] A dye-modified PEG is basic violet 8 modified PEG6000, and the structural formula is as follows:

[0038]

[0039] The synthetic method of described basic violet 8 modified PEG6000 is as follows: take 0.365 grams of basic violet 8, 6 grams of PEG6000 esterified with p-toluenesulfonyl chloride at one end and 0.552 grams of anhydrous potassium carbonate are added to the reactor, and then 50 grams are added. ml of anhydrous acetonitrile, heated and refluxed for 24 hours under nitrogen protection; cooled, filtered, the filtrate was concentrated under reduced pressure, and the obtained oil was recrystallized and purified with diethyl ether to obtain 4.83 g of product with a yield of 78%.

Embodiment 3

[0041] A dye-modified PEG is Rhodamine B-modified PEG1000, and the structural formula is as follows:

[0042]

[0043] The synthetic method of the Rhodamine B-modified PEG1000 is as follows: Dissolve 4.79 g of Rhodamine B in 30 ml of anhydrous dichloromethane, add 0.5 ml of N,N-dimethylformamide to it, and add 0.86 ml of grass under nitrogen protection The acid chloride was stirred and reacted at room temperature for 3 hours; concentrated in vacuo, the residue was dissolved in 30 ml of dry dichloromethane, 10 g of PEG1000 and 4.18 ml of triethylamine were added under nitrogen protection; the mixture was reacted at room temperature for 4 hours; then concentrated under reduced pressure to obtain an oily The oil was recrystallized and purified with ether to obtain 11 g of the product in a yield of 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com