Rim and spoke integral steel wheel manufacturing method

A manufacturing method and integrated technology, applied in the direction of wheels, vehicle parts, transportation and packaging, etc., can solve the problem of low material utilization rate, and achieve the effect of improved material utilization rate, small internal stress, and improved material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and examples.

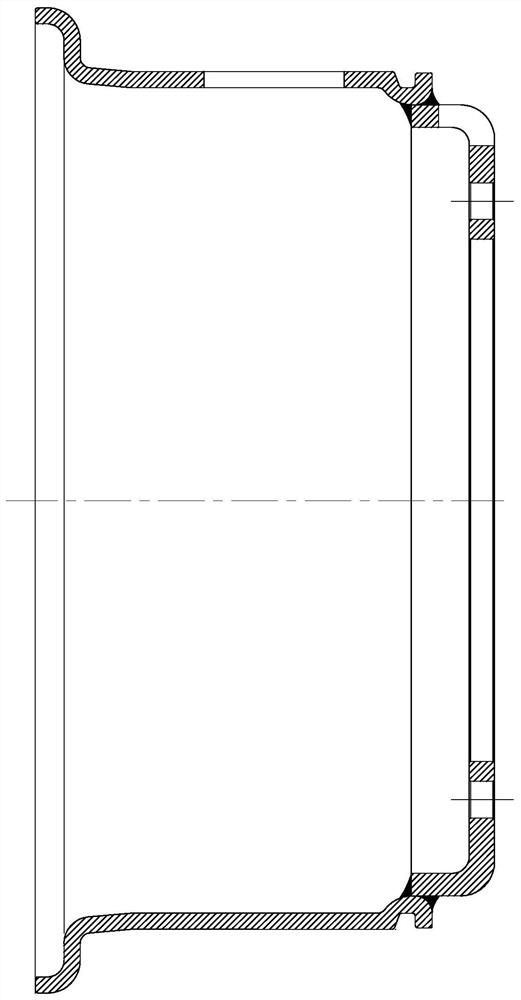

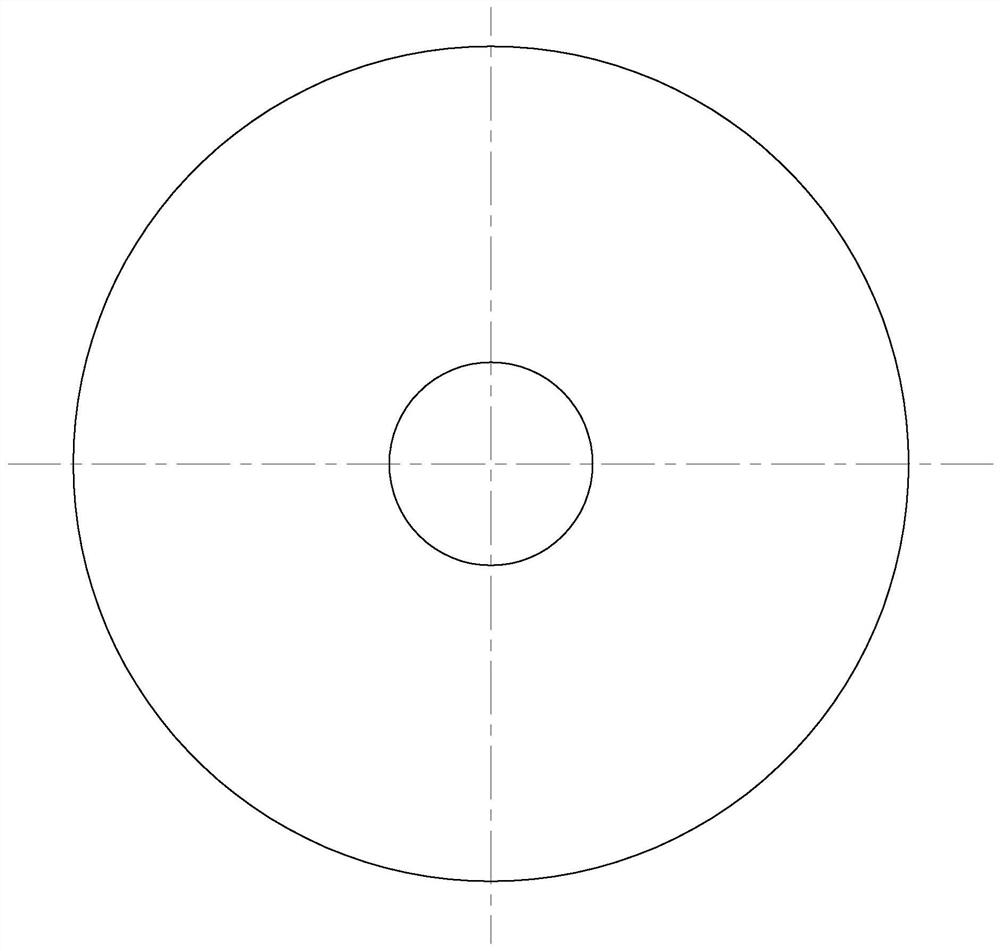

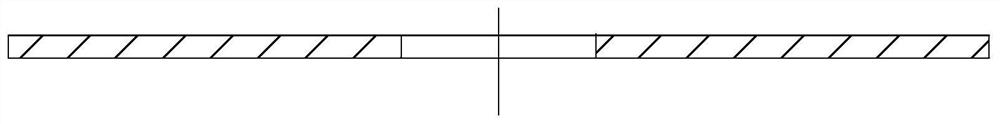

[0042] (1) According to the geometric dimensions of the integrated rim 1 and spoke 2 as follows Image 6As shown, the calculated calculated volume of the wheel, plus 3%-5% of the calculated volume, is used as the billet volume. The burning loss and machining allowance during heating are mainly considered, and steel pipes of corresponding materials are selected according to the billet volume, such as Figure 7 As shown, usually the outer diameter of the steel pipe is the same as the outer diameter of the groove bottom 3 of the rim 1, and the wall thickness of the steel pipe is the same as the thickness of the spoke 2. If there is no suitable steel pipe, it can be rolled with a steel plate of the corresponding thickness and material and welded into a steel pipe. You can also use the whole piece of steel, first forging into a round cake, opening a hole in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com