Efficient environment-friendly recycling system for valuable metals of waste circuit board

A technology of valuable metals and waste circuit boards, applied in the field of circuit boards, can solve the problems of uneven material distribution, adhesion, and low sorting efficiency, and achieve the effects of easy sorting, uniform material spreading, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

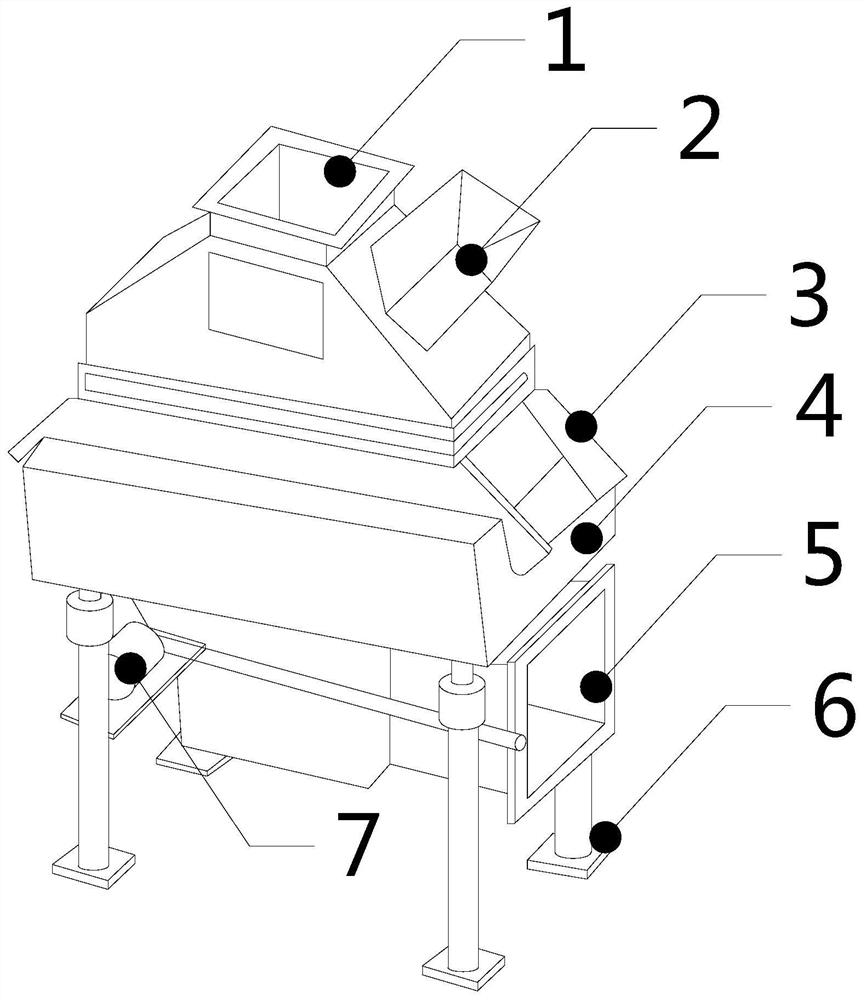

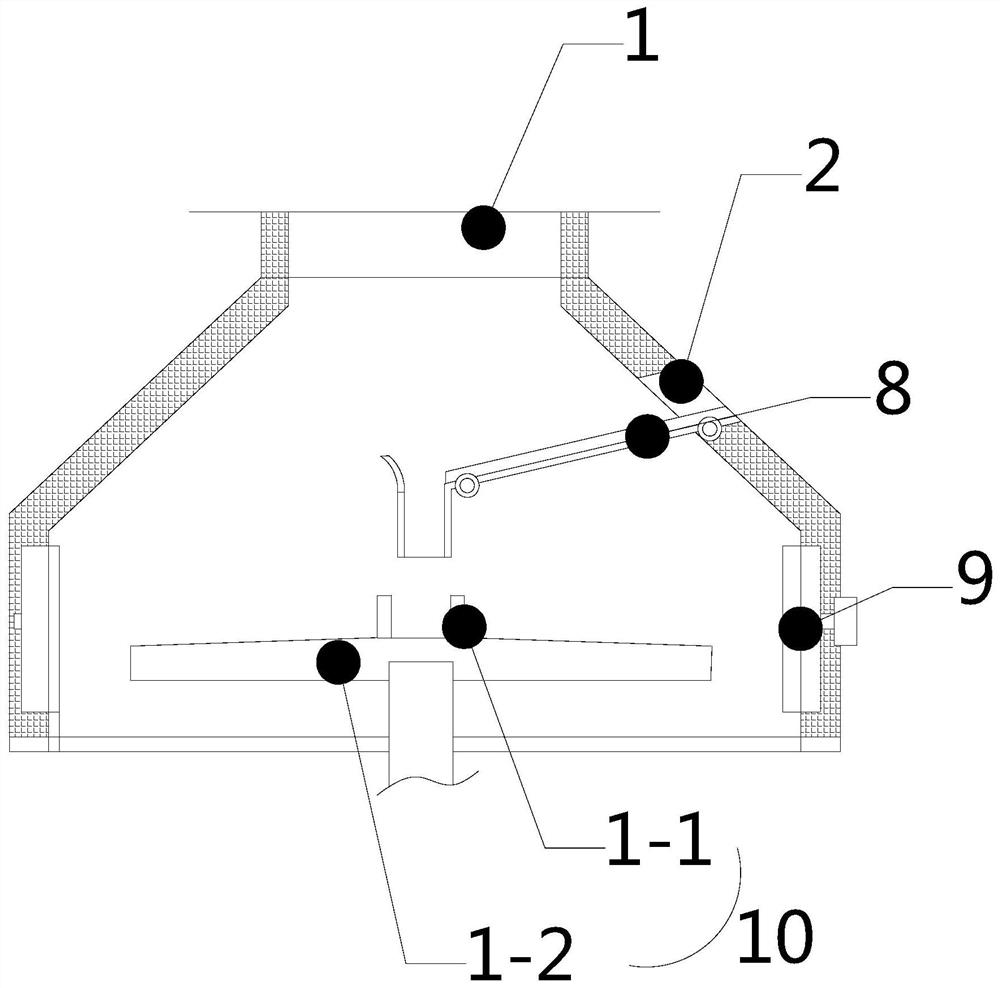

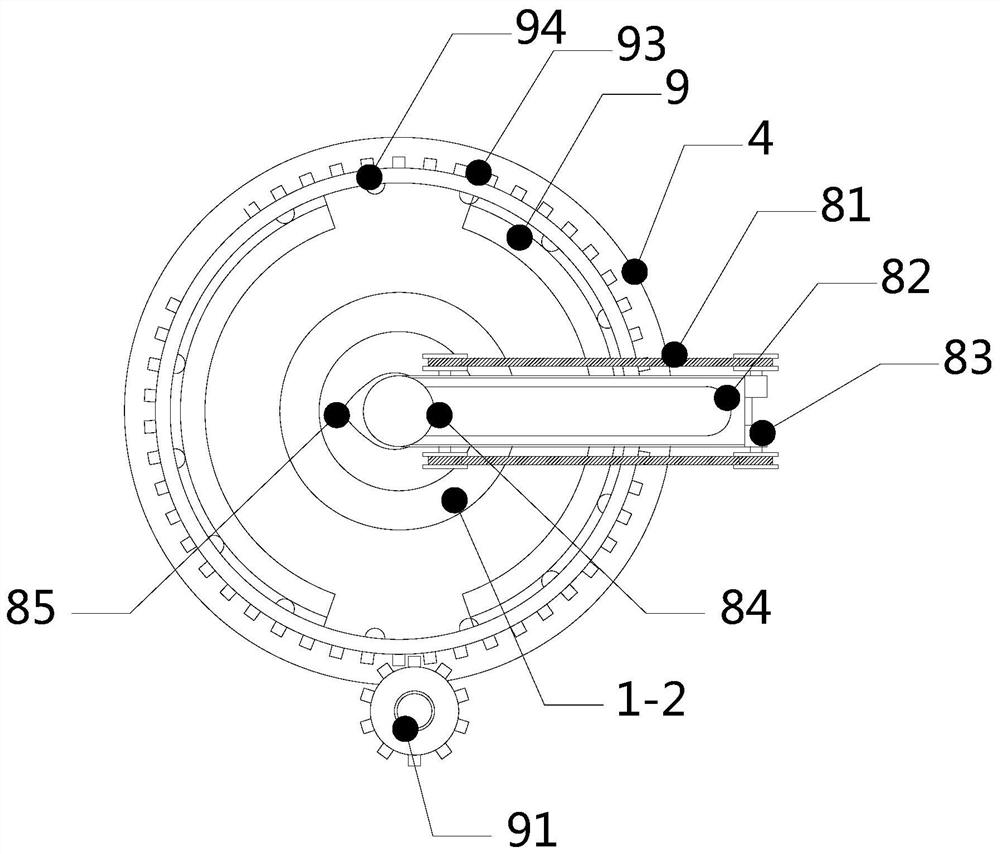

[0025] see Figure 1-Figure 4 , an efficient and environmentally friendly recycling system for valuable metals from waste circuit boards. The present invention provides an efficient and environmentally friendly recycling system for valuable metals from waste circuit boards. Its structure includes a dust outlet 1, a material inlet 2, a material outlet 3, and a body 4 , discharge port 2 5, support feet 6, motor 7, central feeding structure 8, magnetic suction strip 9, material spreading tray 10, dust outlet 1 is installed on the top of the body 4, and a side of the body 4 is opened The feeding port 2, the inside of the body 4 is provided with a spreader 10 in the middle, the bottom of the body 4 is equipped with a motor 7, and the motor 7 is connected to the bottom of the spreader 10 on the middle axis, and the spreader 10 is A central feeding structure 8 is provided directly above, and the central feeding structure 8 cooperates with the spreading tray 10;

[0026] The central ...

Embodiment 2

[0033] see Figure 1-Figure 4, an efficient and environmentally friendly recycling system for valuable metals from waste circuit boards. The present invention provides an efficient and environmentally friendly recycling system for valuable metals from waste circuit boards. Its structure includes a dust outlet 1, a material inlet 2, a material outlet 3, and a body 4 , discharge port 2 5, support feet 6, motor 7, central feeding structure 8, magnetic suction strip 9, material spreading tray 10, dust outlet 1 is installed on the top of the body 4, and a side of the body 4 is opened The feeding port 2, the inside of the body 4 is provided with a spreader 10 in the middle, the bottom of the body 4 is equipped with a motor 7, and the motor 7 is connected to the bottom of the spreader 10 on the middle axis, and the spreader 10 is A central feeding structure 8 is provided directly above, and the central feeding structure 8 cooperates with the spreading tray 10;

[0034] The central f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com