Circulating fluidized bed system for continuously treating organic waste gas

A circulating fluidized bed and organic waste gas technology, which is applied in gas treatment, incinerator, air quality improvement, etc., can solve the problem of failure to provide a good material replenishment method, powdered adsorbent blocking heat, and alternating heating and cooling of equipment Circulation and other issues, to achieve good heat transfer performance, avoid bed explosion, and high mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

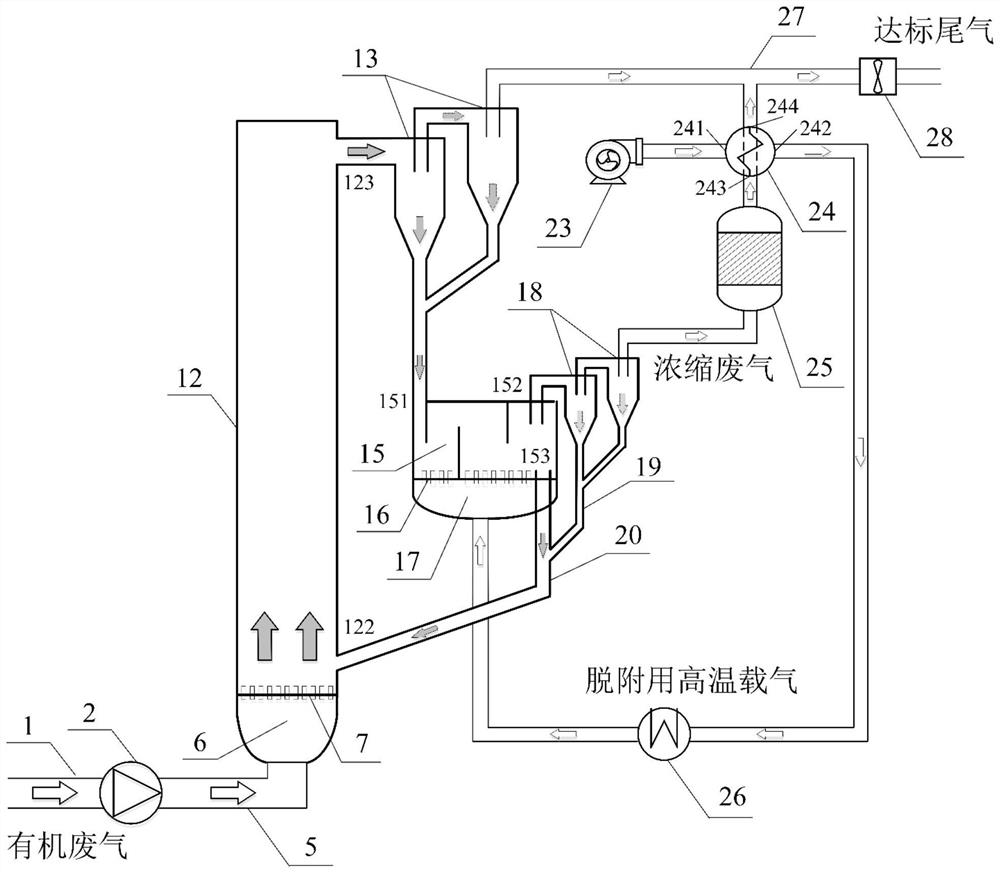

Embodiment 1

[0064] like figure 1 A circulating fluidized bed system 1 for realizing the continuous treatment of organic waste gas is shown. The system includes: an organic waste gas main pipe 1, a fluidization fan 2, a riser air intake main pipe 5, a fluidization wind chamber 6 at the bottom of the riser, Riser air distribution plate 7, riser 12, riser separator 13, desorption chamber 15, desorption chamber air distribution plate 16, desorption carrier gas air chamber 17, desorption chamber separator 18, feed leg 19, desorption Chamber discharge pipe 20, regeneration fan 23, heat exchanger 24, VOCs gas incinerator 25, electric heater 26, exhaust flue 27, induced draft fan 28. The air outlet of the organic waste gas main pipe 1 is provided with a fluidization fan 2, and the air outlet of the fluidization fan 2 is connected to the air inlet of the fluidization air chamber 6 at the bottom of the riser through the riser inlet pipe 5, and the lift pipe 12 is lifted. The discharge port 123 of ...

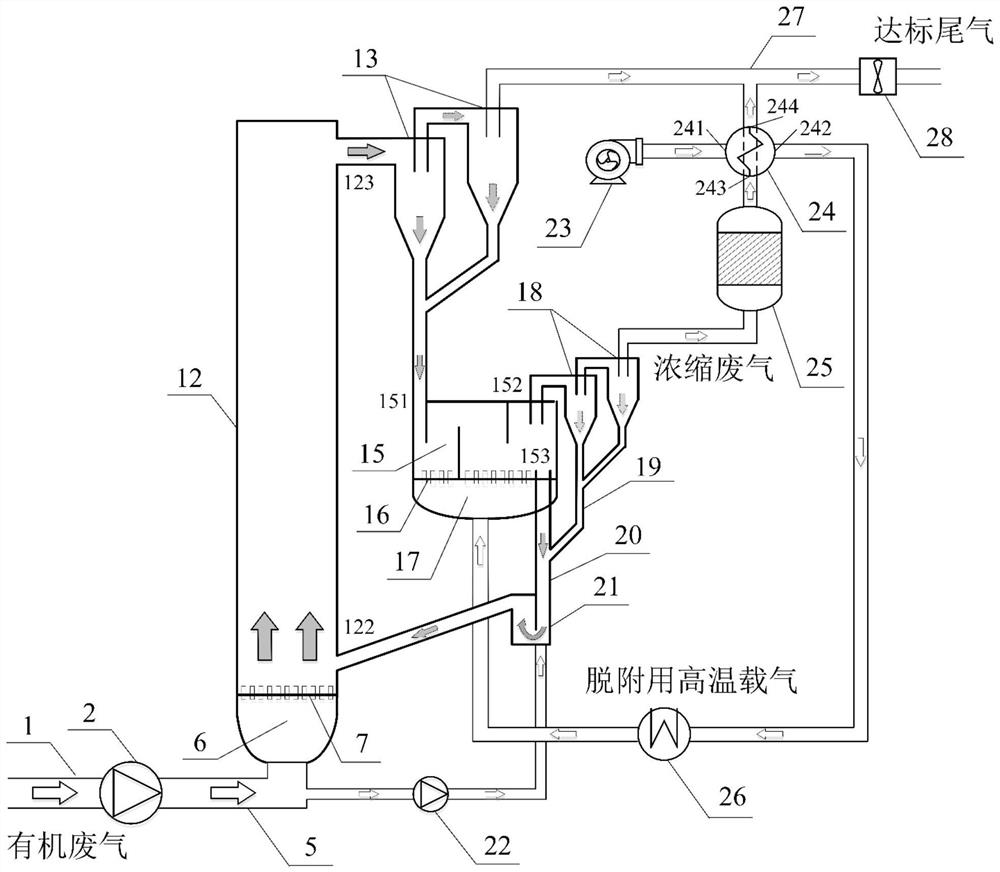

Embodiment 2

[0084] like figure 2 As shown, further, based on the above-mentioned system 1, the present invention also provides an improved circulating fluidized bed system 2 for realizing continuous treatment of organic waste gas. In addition to the components in system 1, system 2 also adds a return device, also known as a particle circulation control device, whose function is not only to adjust and control the particle circulation to achieve the required particle circulation rate; 12 to the desorption chamber 15 "back-channeling" flow, especially for the present system where the reaction process and gas composition in the riser 12 and the desorption chamber 15 are different, it is particularly important to prevent the gas "back-channeling". The material-returning device includes a material-returning valve 21 , a material-returning air booster fan 22 and a corresponding connecting air duct. The return device includes a return valve 21, a return air booster fan 22 and a corresponding co...

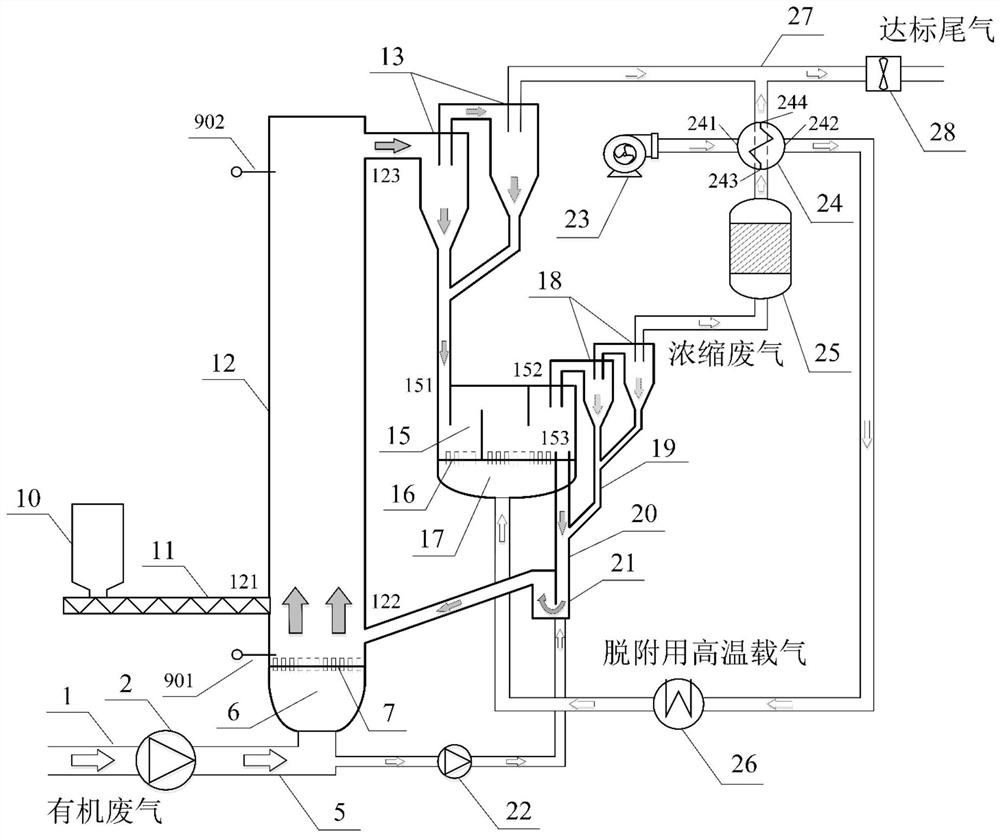

Embodiment 3

[0088] like image 3 As shown, further, based on the above-mentioned system 2, the present invention also provides an improved circulating fluidized bed system 3 for realizing continuous treatment of organic waste gas. In addition to the components in system two, system three also includes a feeding device. The feeding device includes a silo 10 for holding adsorbent particles, a high-pressure screw feeder 11, and the high-pressure screw feeder 11 is arranged in the adsorption The front wall feeding port 121 of the riser 12 of the device and the high-pressure screw feeder 11 are arranged below the silo 10; the catalyst particles in the riser 12 are passed from the silo 10 through the high-pressure screw feeder 11 from the riser 12. into the feeding port 121 of the front wall. In addition, an upper pressure measuring point 902 and a lower pressure measuring point 901 are arranged on the riser 12 , the lower pressure measuring point 901 is arranged on the upper side of the riser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com