Extraction device capable of circularly extracting plant active ingredients

A technology of cyclic extraction and active ingredients, applied in grain processing, solid solvent extraction, etc., can solve the problems of increasing device cost, energy consumption, and large extraction agent consumption, and achieves the improvement of absorption efficiency, filtration efficiency, and extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

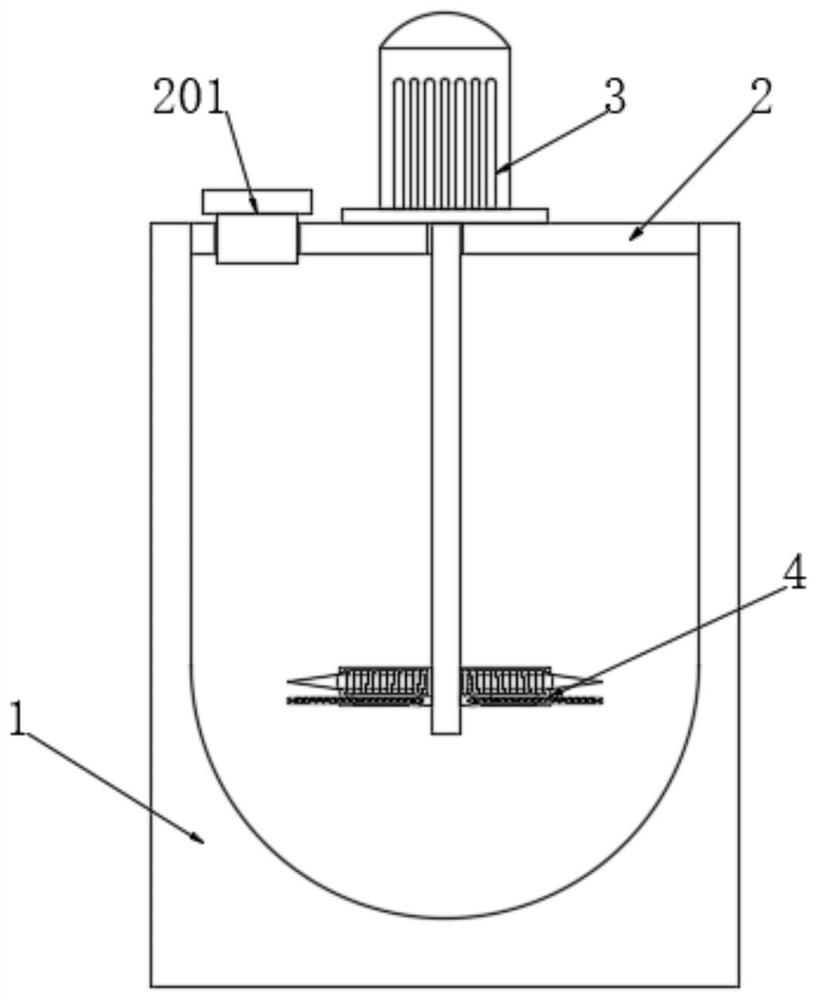

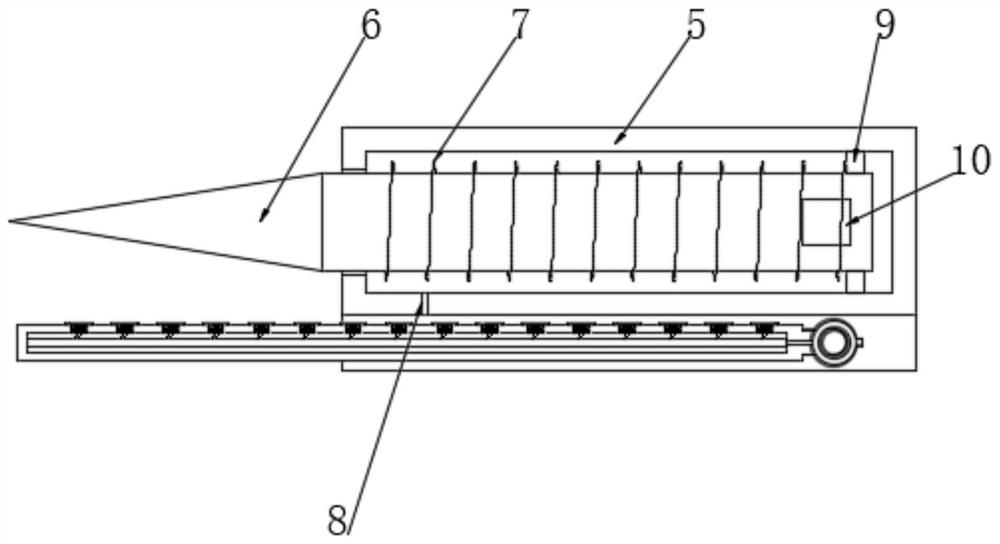

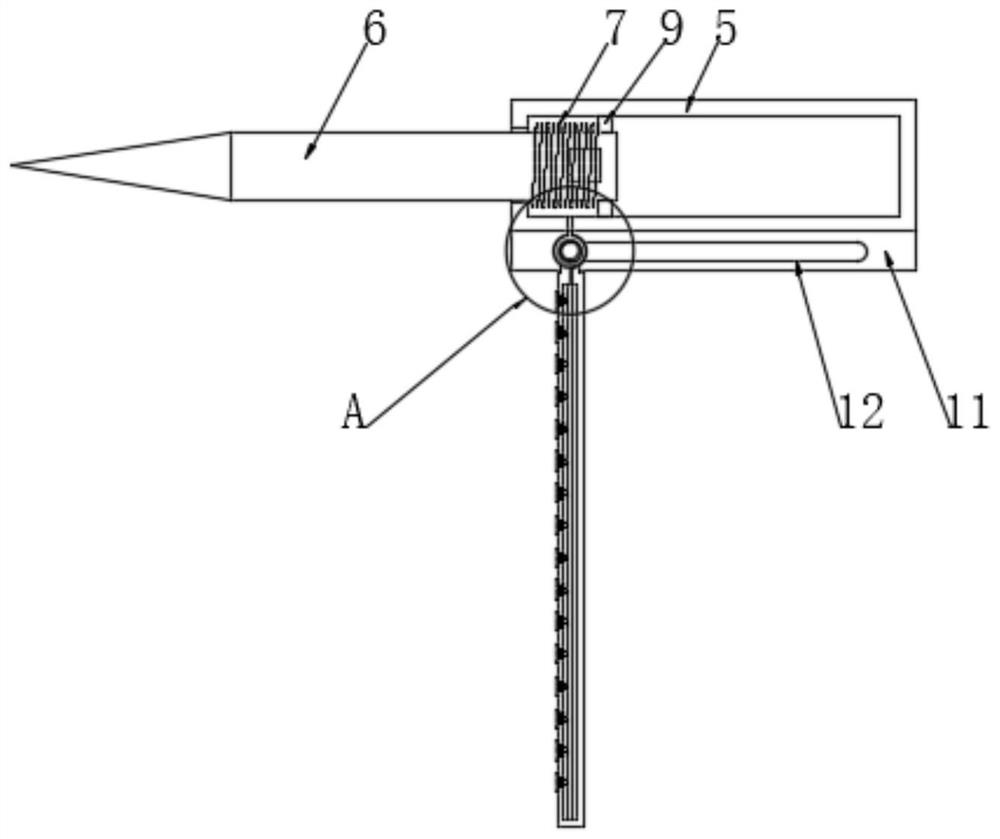

[0043] see Figure 1-4 , an extraction device capable of cyclically extracting plant active ingredients, comprising a cyclic extraction box 1, the inner wall of the cyclic extraction box 1 is threadedly connected with a sealing disc 2, the upper end of the sealing disc 2 is fixedly connected with a motor 3, and the power output end of the motor 3 runs through The outer end of the power output end of the sealed circular plate 2 is fixedly connected with a plurality of uniformly distributed telescopic cutting devices 4, the telescopic cutting device 4 includes a storage blade frame 5, the storage blade frame 5 is filled with extraction agent, and the storage blade frame 5 A movable cutting blade 6 is slidingly connected inside, a compression spring 7 is arranged between the storage blade frame 5 and the movable cutting blade 6, a release hole 8 is dug at the bottom of the storage blade frame 5, and the outer end of the movable cutting blade 6 is fixedly connected with a storage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com