Blue light device with high efficiency and long service life

A long-life, blue-light technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of reducing the efficiency and life of blue-light devices, blue phosphorescent devices cannot meet practical applications, etc., and achieve low working voltage , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

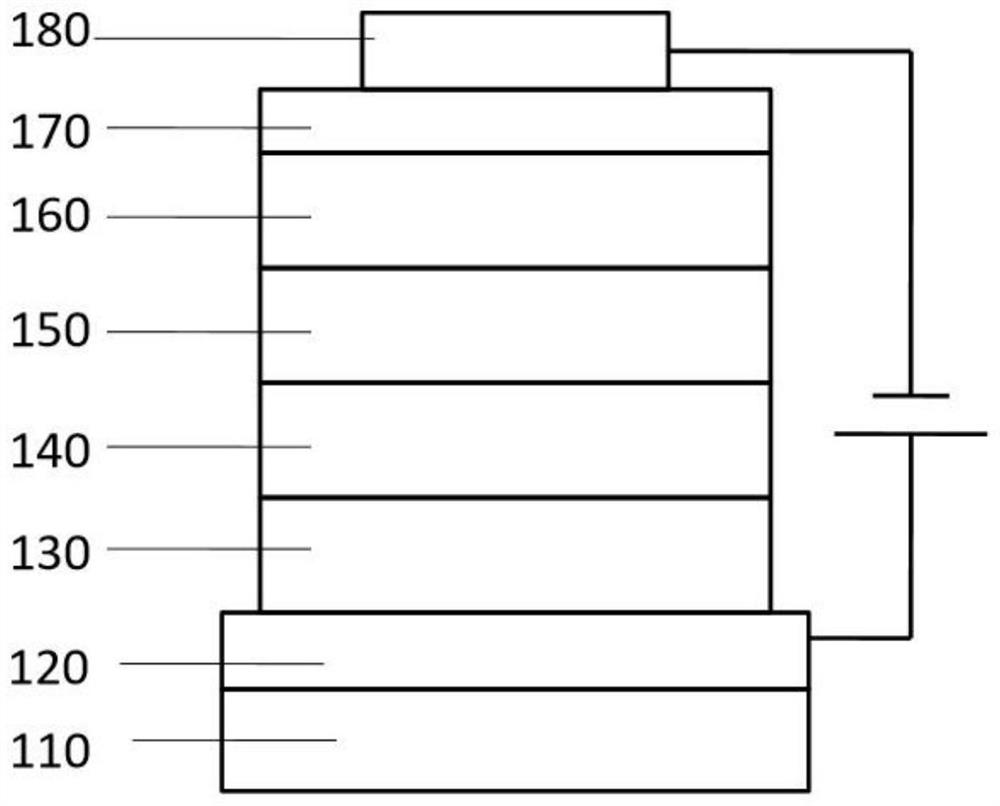

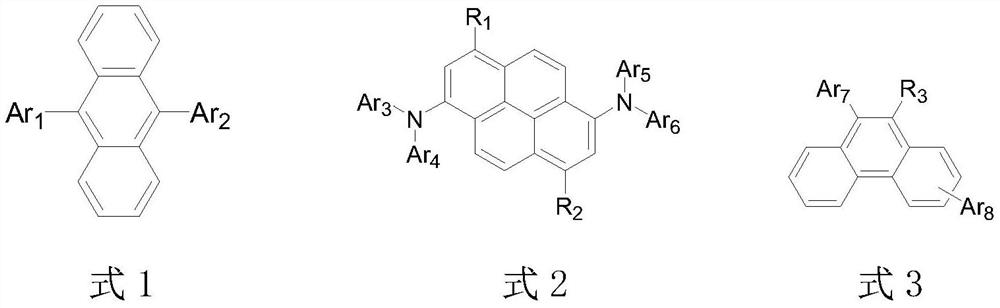

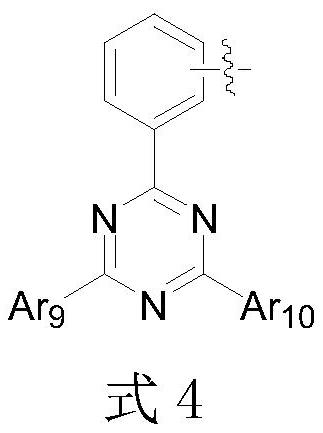

[0057] First, the transparent conductive ITO glass substrate 110 (with the anode 120 on it) (CSG Group Co., Ltd.) was washed with deionized water, ethanol, acetone, and deionized water in sequence, and then treated with oxygen plasma for 30 seconds. Next, a 5 nm thick HIL was evaporated on the anode 120 as the hole injection layer 130; the compound HTL was continuously evaporated to form a 70 nm thick hole transport layer 140. Then, a 25-nm-thick light-emitting layer 150 was vapor-deposited on the hole transport layer, in which BH6 was the host light-emitting material, and 3% by weight of BD6 was used as the guest material. Then, an electron transport layer 160 with a thickness of 25 nm is vapor-deposited on the light-emitting layer, wherein the ratio of ET2 and LiQ is 50:50. Finally, vapor deposition of 1 nm LiF as the electron injection layer 170 and 100 nm Al as the device cathode 180.

[0058] The prepared device uses Photo Research PR650 spectrometer at 10mA / cm 2 The test w...

Embodiment 2

[0060] The difference from Example 1 is that the guest material in the light-emitting layer uses BD8 instead of BD6, and the electron transport material uses ET6 instead of ET2.

Embodiment 3

[0062] The difference from Example 1 is that the host material in the light-emitting layer uses BH9 instead of BH6, and the electron transport material uses ET6 instead of ET2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com