A Quantitative Characterization Method of Single Crystal Alloy Rafting Based on Digital Image Algorithm

A digital image and alloy technology, which is applied in the field of testing and characterization of the microstructure of materials, can solve the problems of lack of quantitative determination methods for rafting, and can not reflect the change of strengthening phase size, etc., to reduce costs and errors, fast operation, and good project promotion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the advantages of the technical method of the present invention clearer and make it easier for those skilled in the art to implement, the specific operation of the present invention will be further described below in conjunction with the accompanying drawings and embodiments of the invention. It should be pointed out that the examples are only to make the advantages and operating methods of the present invention easier for those skilled in the art to understand and grasp, but not to limit the application of the present invention to single crystal and directionally solidified turbine blade rafted structure characterization and other related occasions.

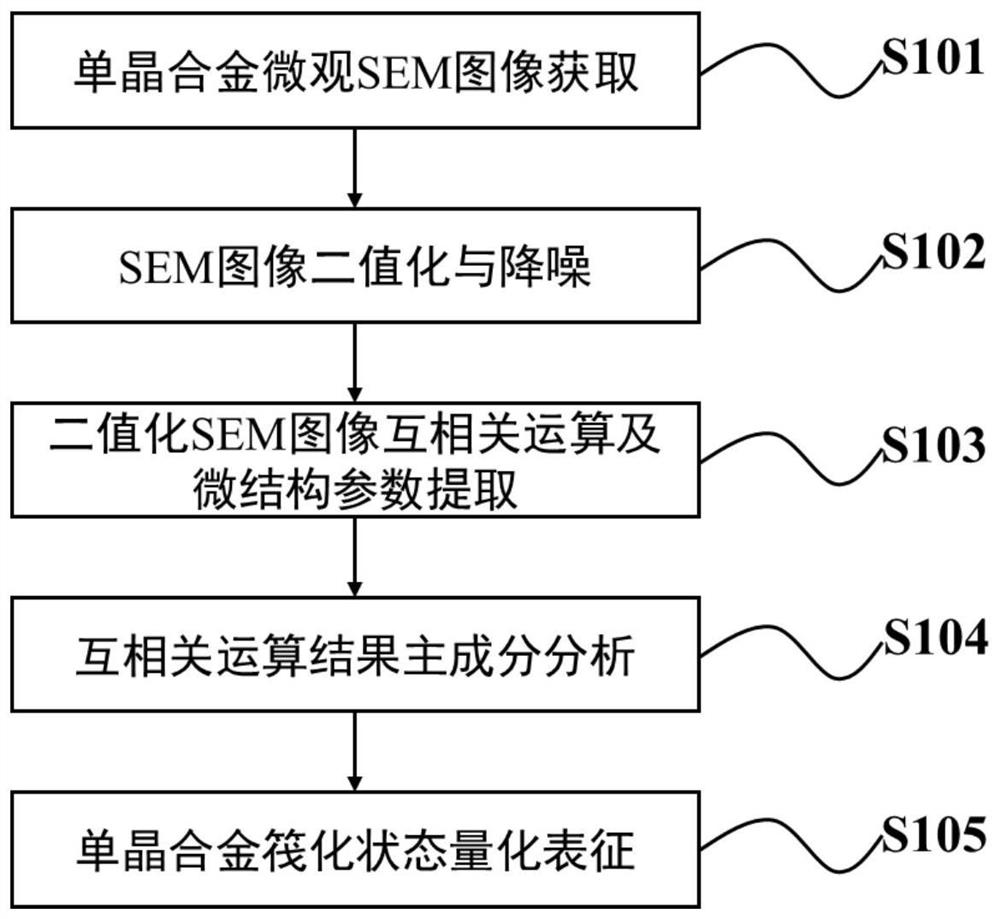

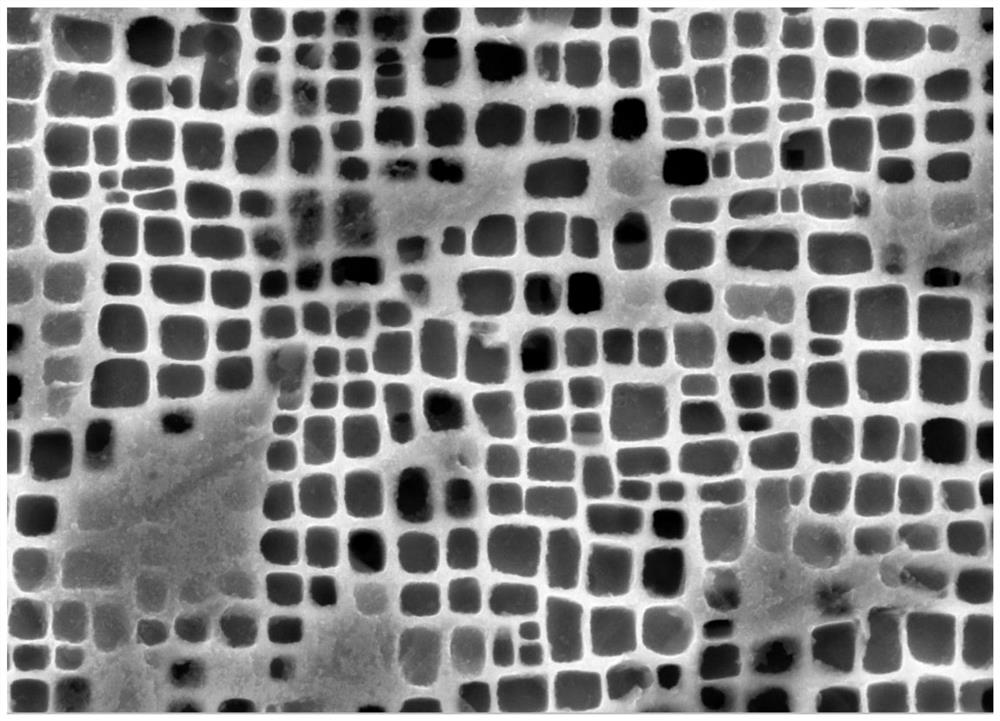

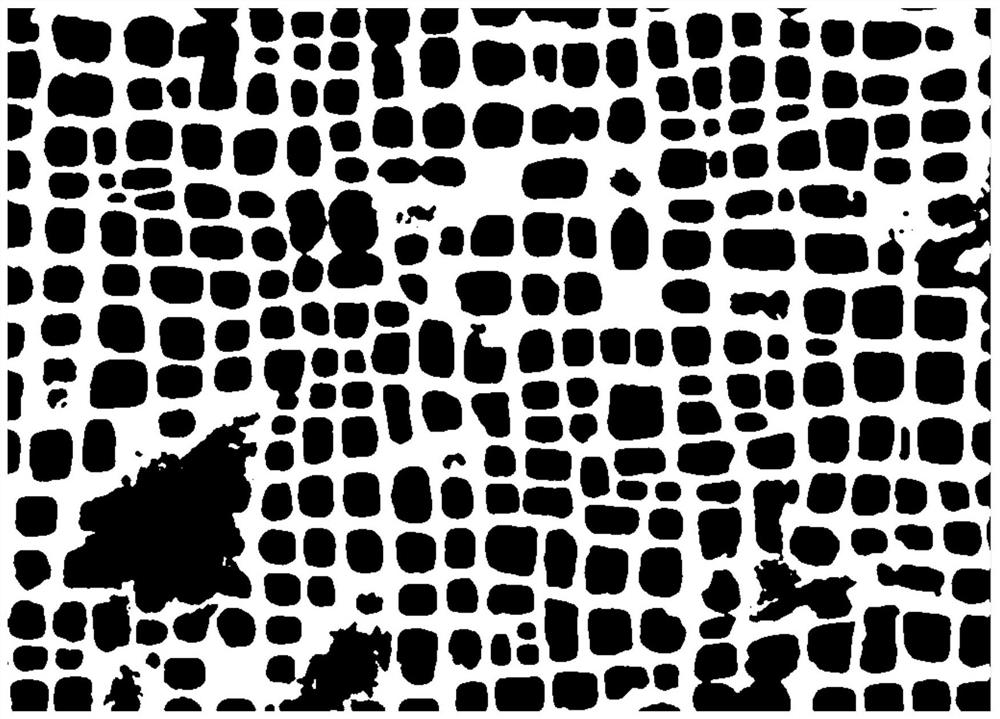

[0067] The present invention provides a single crystal alloy rafting quantitative characterization method based on digital image algorithm, see figure 1 , is a simple flow chart of the rafting quantitative characterization method for a certain type of single crystal nickel-based superalloy provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com