A road crack treatment device

A technology for treating devices and cracks, applied in the directions of roads, roads, and road repair, can solve the problems of inconvenient use, time-consuming and labor-intensive, etc., and achieve the effect of high treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

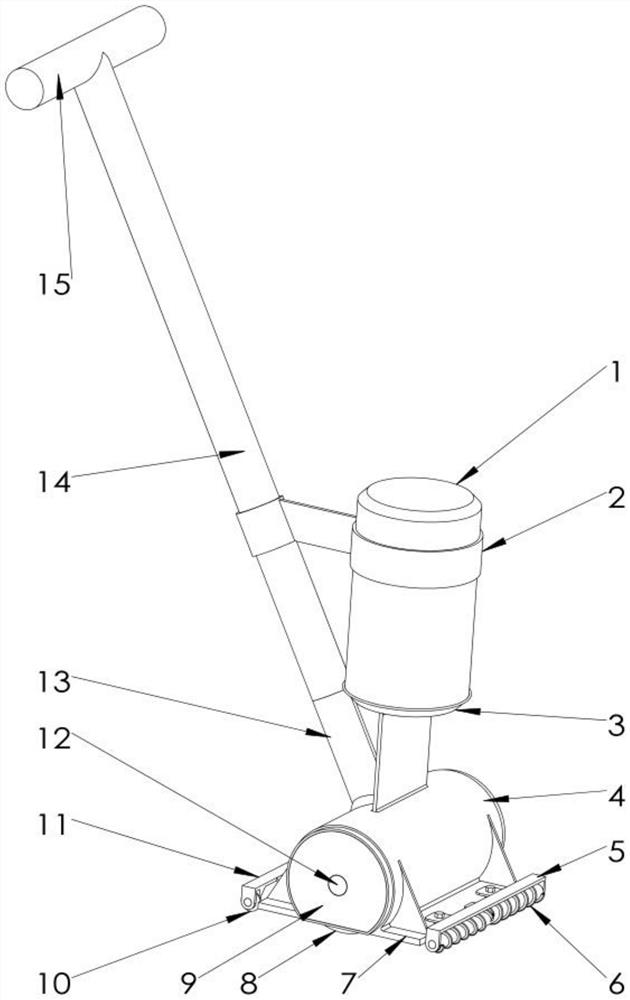

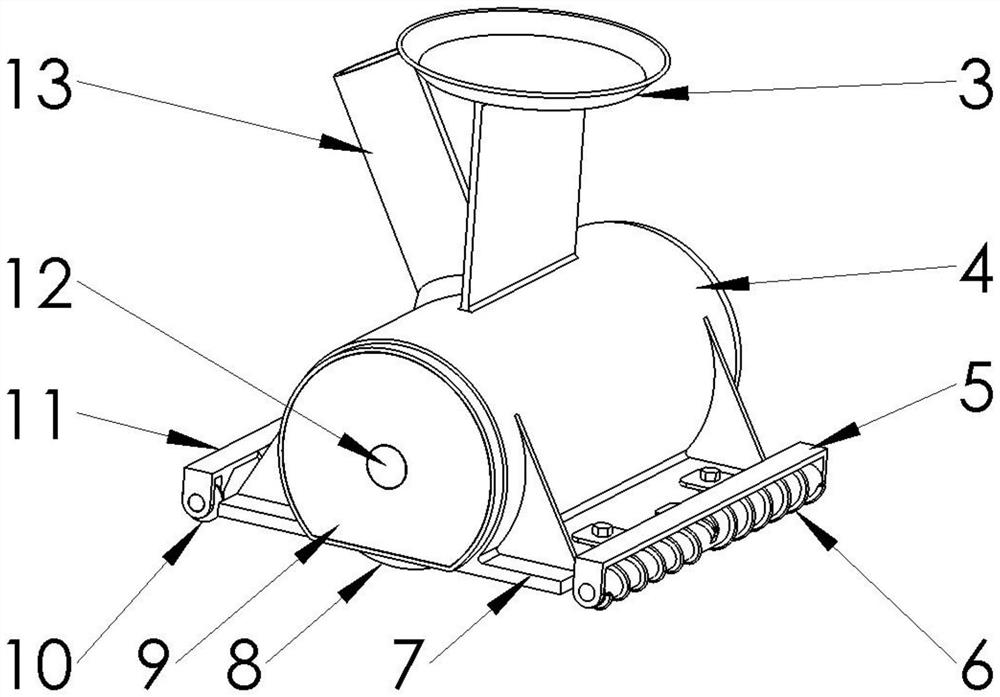

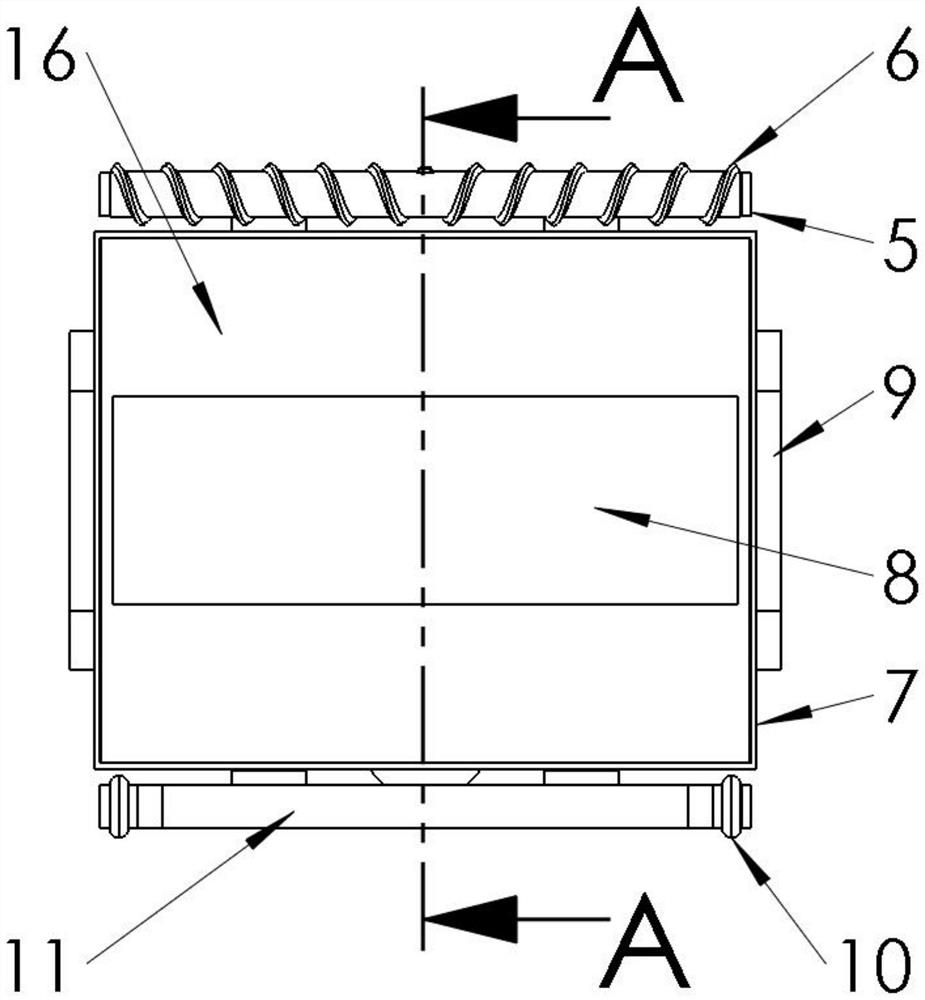

[0025] as attached figure 1 - attached image 3 As shown, the present invention provides a kind of highway crack treatment device, comprises pressure roller 8, joint frame and push rod, pressure roller 8 is hinged on the joint frame, is provided with push rod on the joint frame, and joint frame comprises main body, battery frame, Battery pack 1, spreading roller, electric heating winding 17, pressure roller 8 are embedded and hinged in the middle of the main body, a battery rack is fixedly installed on the upper end of the main body, and a battery pack 1 is arranged on the battery rack, and a battery pack 1 is arranged in the main body. Group 1 is electrically connected to the electric heating winding 17, and the electric heating winding 17 is reciprocally bent and distributed in the main body to heat the pressure roller 8;

[0026] The front end of the main body is equipped with spreading rollers, so that both sides of the seam tape are spread out, and the pressure roller 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com