Cracking-resistant polyurethane synthetic leather and preparation method thereof

A polyurethane and synthetic leather technology, applied in the field of synthetic leather, can solve the problems of easy detachment of yarn, failure to maintain structure, cracking of synthetic leather, etc., and achieve the effect of not easy to detach, increase bonding strength, and improve the ability to resist external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of anti-split polyurethane synthetic leather, comprising base cloth, polyurethane adhesive layer and polyurethane surface layer;

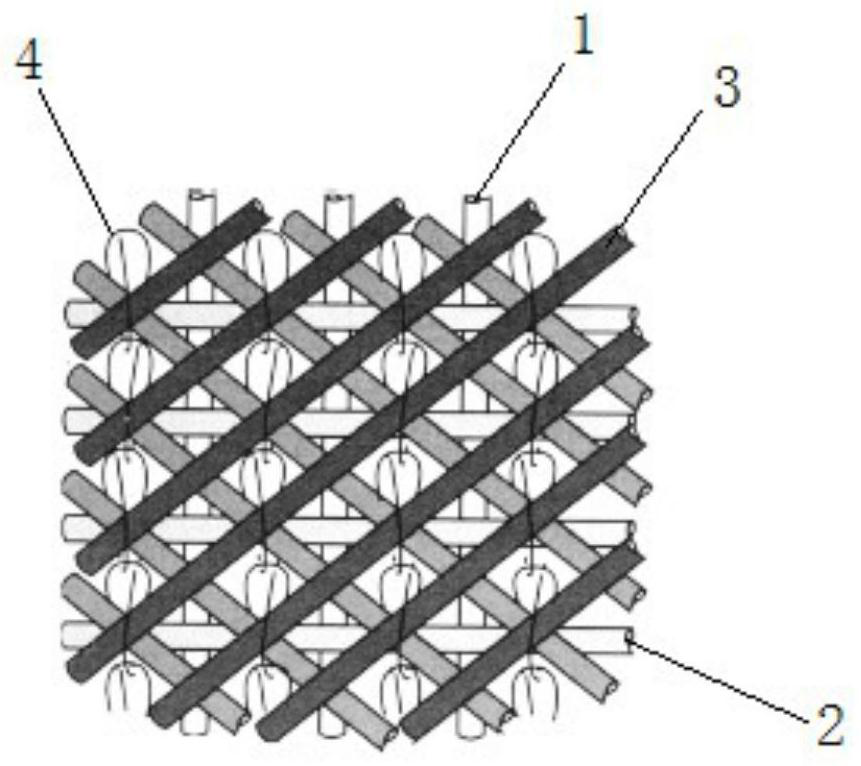

[0028] The base fabric is a warp knitted fabric, such as figure 1 As shown, the warp-knitted fabric is woven with warp-lining yarn 1, weft-lining yarn 2, diagonal lining yarn 3 and loop-forming yarn 4, and warp-lining yarn 1, weft-lining yarn 2, diagonal lining yarn 3 and loop-forming yarn 4 are all used Polyester yarn, in which the loop-forming yarn 4 is woven into a flat weave. During the knitting process of the loop-forming yarn, the lining warp yarn 1 is inserted along the warp direction of the fabric in a straight state, and the weft yarn 2 is parallel to the weft direction of the fabric. Stretching state interlining, oblique interlining yarn 3 parallel to the oblique direction of the fabric and interlining in a straight state, interlining warp yarn 1, weft inlay yarn 2, oblique interlining yarn 3 do not form loops, loop forming ...

Embodiment 2

[0032] A kind of anti-split polyurethane synthetic leather, comprising base cloth, polyurethane adhesive layer and polyurethane surface layer;

[0033] The base fabric is a warp-knitted fabric, which is woven with warp-lining yarn, weft-lining yarn, diagonal lining yarn and loop-forming yarn, and the warp-lining yarn, weft lining yarn, diagonal lining yarn and loop-forming yarn are all made of polyester yarn , where the loop-forming yarn is woven into a flat weave. During the knitting process of the loop-forming yarn, the interlining warp yarn is inserted along the warp direction of the fabric in a straightened state, and the weft-inlaid yarn is inserted in a parallel and straightened state along the weft direction of the fabric. , the oblique interlining yarn is inserted parallel to the oblique direction of the fabric and in a straight state. The interlining warp yarn, weft interlining yarn, and oblique interlining yarn do not form loops, and the loop-forming yarns are woven i...

Embodiment 3

[0037] A kind of anti-split polyurethane synthetic leather, comprising base cloth, polyurethane adhesive layer and polyurethane surface layer;

[0038] The base fabric is a warp-knitted fabric, which is woven with warp-lining yarn, weft-lining yarn, diagonal lining yarn and loop-forming yarn, and the warp-lining yarn, weft lining yarn, diagonal lining yarn and loop-forming yarn are all made of polyester yarn , in which the loop-forming yarn is woven into a warp fabric. During the loop-forming yarn weaving process, the interlining warp yarn is inserted along the warp direction of the fabric in a straightened state, and the weft-inlaid yarn is inserted in a parallel and straightened state along the weft direction of the fabric. , the oblique interlining yarn is inserted parallel to the oblique direction of the fabric and in a straight state. The interlining warp yarn, weft interlining yarn, and oblique interlining yarn do not form loops, and the loop-forming yarns are woven into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com