A method for dezincification of galvanized scrap steel

A technology for dezincification and scrap steel, applied in the direction of instruments, control/regulating systems, and process efficiency improvement, etc., can solve the problems of difficult recovery of zinc on the surface of scrap steel, difficult control of process parameters, and diffusion, etc., to ensure dezincification efficiency, The effect of promoting rapid evaporation and reducing diffusion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

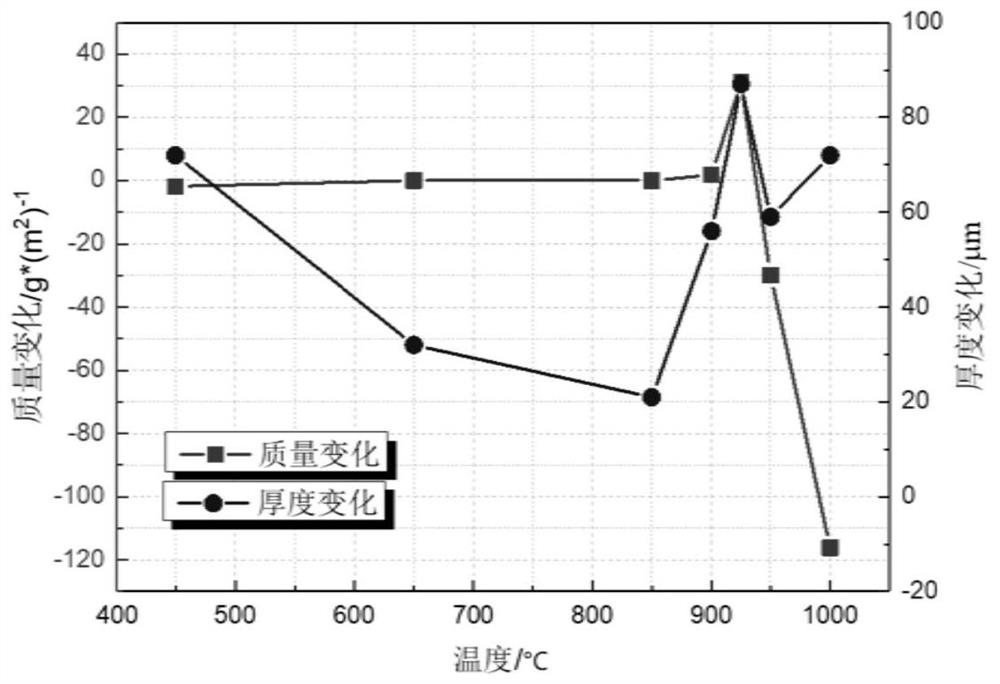

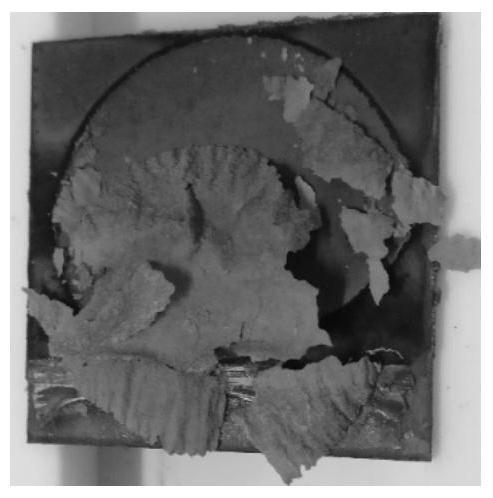

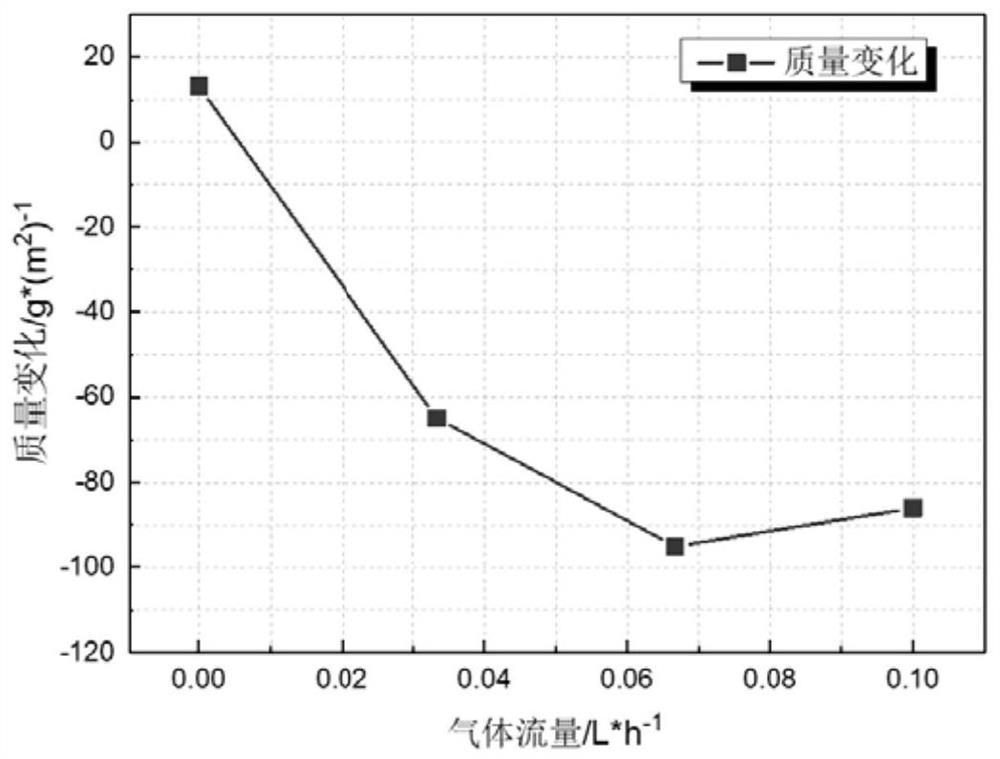

Embodiment 1

[0031] A method for dezincifying galvanized steel scrap in this embodiment, mixing galvanized steel scrap with coke powder, the mass ratio of galvanized steel scrap to coke powder is 1:0.367, and the mass of coke powder with a particle size of 0.5 mm to 5 mm accounts for the total coke powder. more than 85% of the powder quality, and the quality of 2.5~3mm coke powder accounts for more than 85% of the total coke powder quality in the present embodiment, the galvanized steel scrap that is mixed with coke powder is placed in the rotary kiln for dezincification, and the rotary kiln speed is : 1.8s / r; the galvanized steel scrap is a steel plate, and the mass percentages of elements in the galvanized layer are: Zn: 62% to 68%; Fe: 25% to 29%; S: 3.5% to 5.5%; Mn: 0.035 % to 0.085%; Al: 0.50% to 0.75%, and the rest are other elements; the steel plates are placed in the rotary kiln in a non-stacked state. Raise the temperature of the rotary kiln to 900°C with a heating rate of 10°C / m...

Embodiment 2

[0033] A method for dezincifying galvanized steel scrap in this embodiment, mixing galvanized steel scrap with coke powder, the mass ratio of galvanized steel scrap to coke powder is 1:0.367, and the mass of coke powder with a particle size of 0.5 mm to 5 mm accounts for the total coke powder. more than 85% of the powder quality, and the quality of 2.5~3mm coke powder accounts for more than 85% of the total coke powder quality in the present embodiment, the galvanized steel scrap that is mixed with coke powder is placed in the rotary kiln for dezincification, and the rotary kiln speed is : 1.8s / r; the galvanized steel scrap is a steel plate, and the mass percentages of elements in the galvanized layer are: Zn: 62% to 68%; Fe: 25% to 29%; S: 3.5% to 5.5%; Mn: 0.035 % to 0.085%; Al: 0.50% to 0.75%, and the rest are other elements; the steel plates are placed in the rotary kiln in a non-stacked state. Raise the temperature of the rotary kiln to 950°C with a heating rate of 10°C / m...

Embodiment 3

[0035]A method for dezincifying galvanized steel scrap in this embodiment, mixing galvanized steel scrap with coke powder, the mass ratio of galvanized steel scrap to coke powder is 1:0.367, and the mass of coke powder with a particle size of 0.5 mm to 5 mm accounts for the total coke powder. more than 85% of the powder quality, and the quality of 2.5~3mm coke powder accounts for more than 85% of the total coke powder quality in the present embodiment, the galvanized steel scrap that is mixed with coke powder is placed in the rotary kiln for dezincification, and the rotary kiln speed is : 1.8s / r; the galvanized steel scrap is a steel plate, and the mass percentages of elements in the galvanized layer are: Zn: 62% to 68%; Fe: 25% to 29%; S: 3.5% to 5.5%; Mn: 0.035 % to 0.085%; Al: 0.50% to 0.75%, and the rest are other elements; the steel plates are placed in the rotary kiln in a non-stacked state. Raise the temperature of the rotary kiln to 1000°C with a heating rate of 10°C / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com