Method for producing polysialic acid by using fermentation process, and extraction and refining method for polysialic acid

A technology of polysialic acid and fermentation method, which is applied in the field of bioengineering to achieve the effects of saving costs, reducing energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

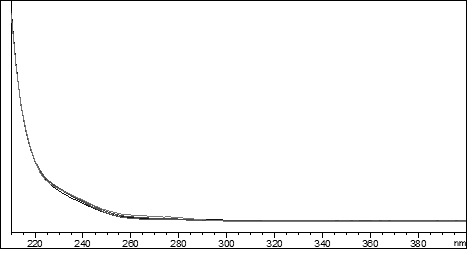

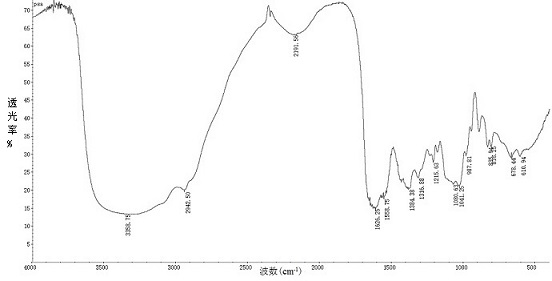

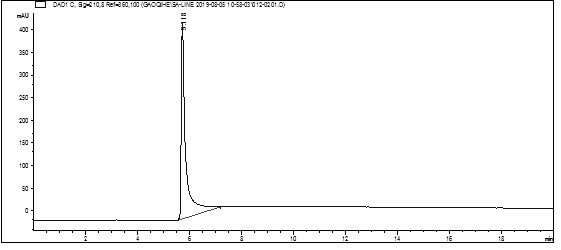

Image

Examples

Embodiment 1

[0034] The fermentation strain is Escherichia coli SA-8 screened by mutagenesis in the Industrial Microbiology Laboratory of the Institute of Microbiology, Chinese Academy of Sciences, and its patent preservation number is CGMCC NO.5585.

[0035] A method for producing polysialic acid by fermentation, comprising the following steps:

[0036](1) Escherichia coli SA-8 with a volume percentage of 2% was inoculated in the basal medium of the seed tank, and the seed culture liquid was obtained by fermentation culture, and the seed tank was fermented in 1000 liters. The basal medium used is glucose 25g / L, ammonium sulfate 5g / L, casein peptone 15g / L, dipotassium hydrogen phosphate 20g / L, magnesium sulfate 0.4g / L, after mixing evenly, steam sterilization. After reaching 121°C, maintain the tank pressure at 0.09MPa and sterilize for 30 minutes. The sterilization process requires continuous stirring at 200rpm. After cooling, inoculate 9 liters of bacterial cell culture solution and in...

Embodiment 2

[0041] The fermentation broth obtained in Example 1 was used. Carry out the extraction and refinement of polysialic acid according to the following steps:

[0042] (1) Separation of bacterial liquid: 200nm ceramic membrane removes bacterial cells, and the clear liquid first passes through a weakly basic anion exchange resin to change ammonium polysialate into sodium polysialate;

[0043] (2) Removal of small molecular impurities: the ion-exchanged sodium polysialate solution is ultrafiltered with a 70,000 Dalton membrane system to concentrate macromolecules; and the concentrated sodium polysialate solution is washed with pure water to a pH below 7.2, and the filtered Discard the waste liquid and keep the concentrate.

[0044] (3) Ethanol precipitation of PSA: Add three times the volume of absolute ethanol to the concentrated and washed polysialic acid sodium solution, let it stand and cool down to below 8°C, and after maintaining it for 1 hour, collect the polysialic acid pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com