A fixed-length automatic cutting device and cutting process for manufacturing color steel tiles

A cutting device and color steel tile technology, which is applied to shearing devices, manufacturing tools, accessories of shearing machines, etc. Inability to cut color steel tiles and other problems, to achieve the effect of facilitating the operation of the cutting mechanism, reducing the intensity of manual work and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

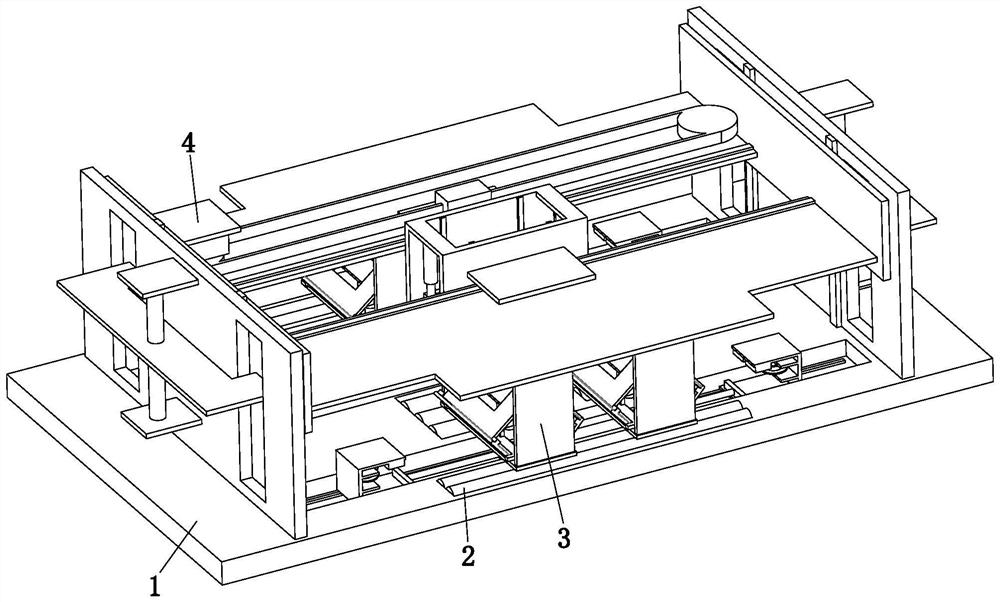

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination figure 1 to Figure 7 , to further elaborate the present invention.

[0027] A fixed-length automatic cutting device for color steel tile manufacturing, including an installation base plate 1, a guide mechanism 2, a positioning mechanism 3 and a cutting mechanism 4, the installation base plate 1 is equipped with a guide mechanism 2, and the installation base plate 1 is equipped with a positioning mechanism 3, and the positioning mechanism 3 is located above the guiding mechanism 2, and the cutting mechanism 4 is installed on the positioning mechanism 3 through sliding fit.

[0028]Described guide mechanism 2 comprises two-way cylinder 2a, rectangular notch one 2b, rectangular notch two 2c, rectangular notch three 2d, guide cylinder one 2e, guide cylinder two 2f, guide wheel 2g, guide frame 2h, rotating The shaft 2j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com