Pouring system of copper art crafts

A technology for copper handicrafts and liquid storage, which is used in manufacturing tools, metal processing equipment, equipment for feeding molten metal into casting molds, etc. It is convenient for batch pouring, convenient for stable pouring, and easy to stabilize the effect of copper crafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

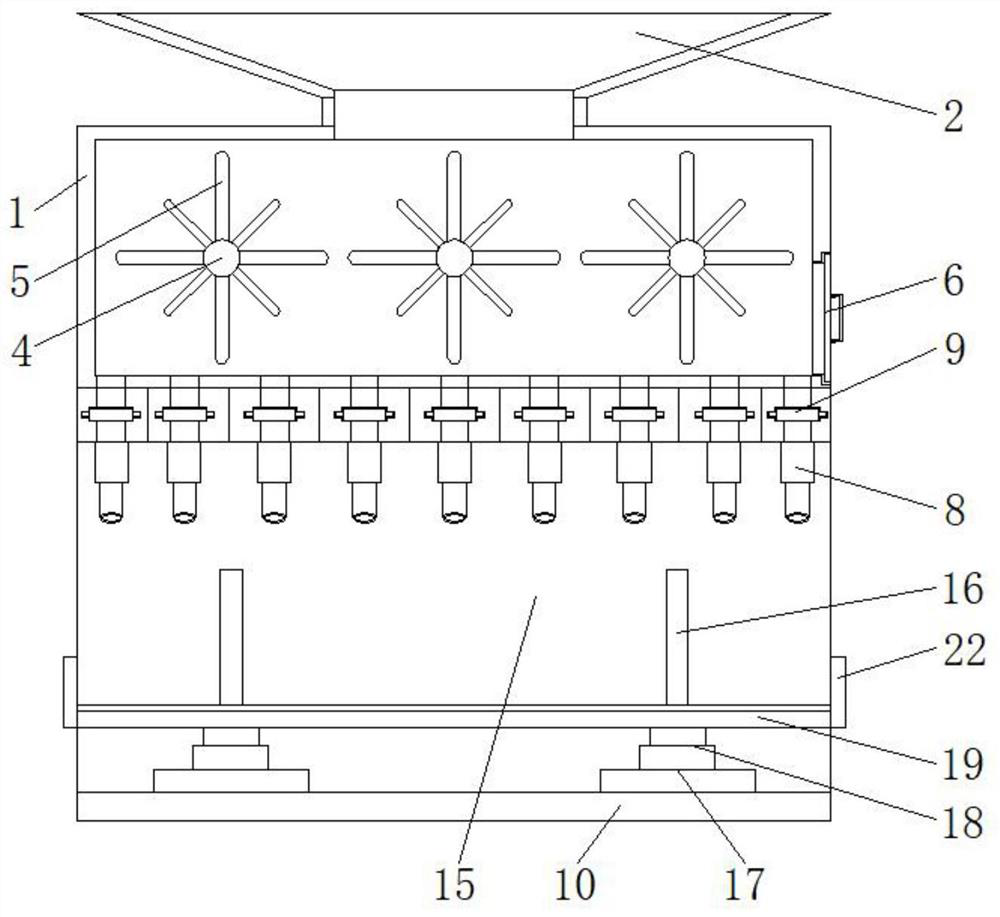

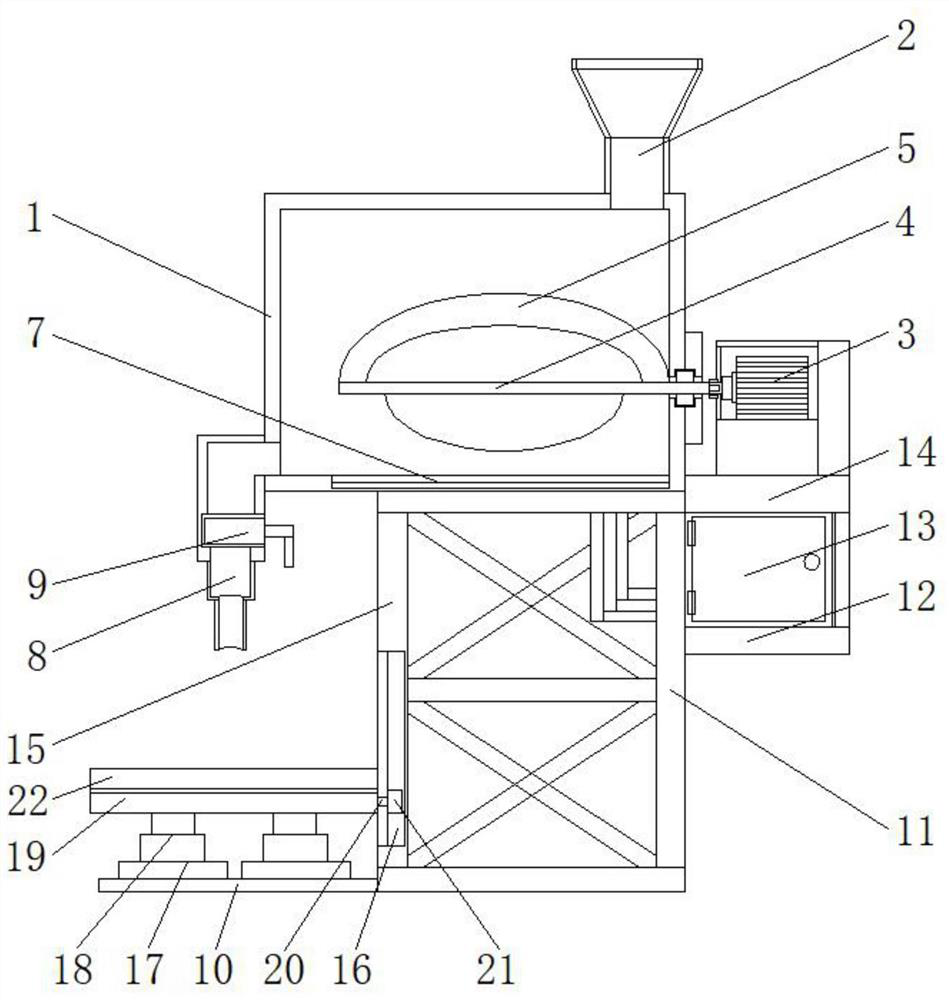

[0024] The support mechanism includes a base 10, the back of the base 10 is fixedly connected with a support frame 11, the upper surface of the support frame 11 is fixedly connected with the lower surface of the liquid holding tank 1 through a flat plate, and the back surface of the support frame 11 is fixedly connected with a support plate 12, The upper surface of the support plate 12 is fixedly connected with a distribution box 13, the lower surface of the heating plate 7 is electrically connected with the electrical appliances inside the distribution box 13 through a circuit, and the back side of the output pipe 8 is provided with a groove that is compatible with the clamping plate 9. And the shape of the clamping plate 9 is φ type, the upper surface of the distribution box 13 is fixedly connected with a fixed plate 14, and the number of the transmission rods 4 is three, and two of the transmission rods 4 pass through the belt and the motor on the back of the liquid tank 1 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com