LED structure and LED screen thereof

A technology of LED structure and LED chip, which is applied in the direction of instruments, electrical components, circuits, etc., can solve the problems of increasing the overall weight of the LED screen, increasing the overall weight of the LED structure, and failing to achieve efficient heat dissipation, so as to improve the brightness of lighting and lighting The effect of improving the range of use and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

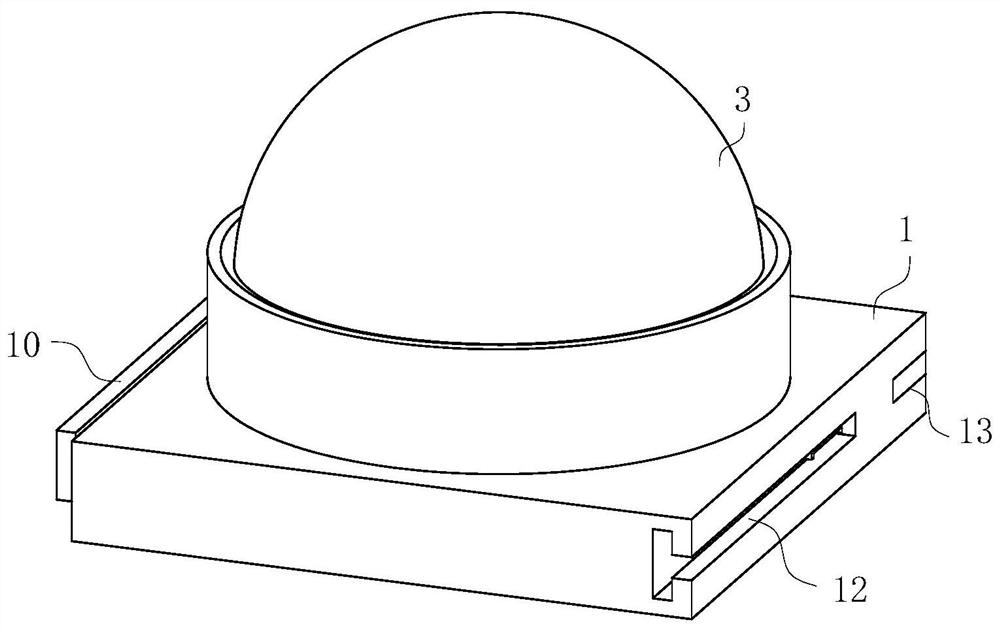

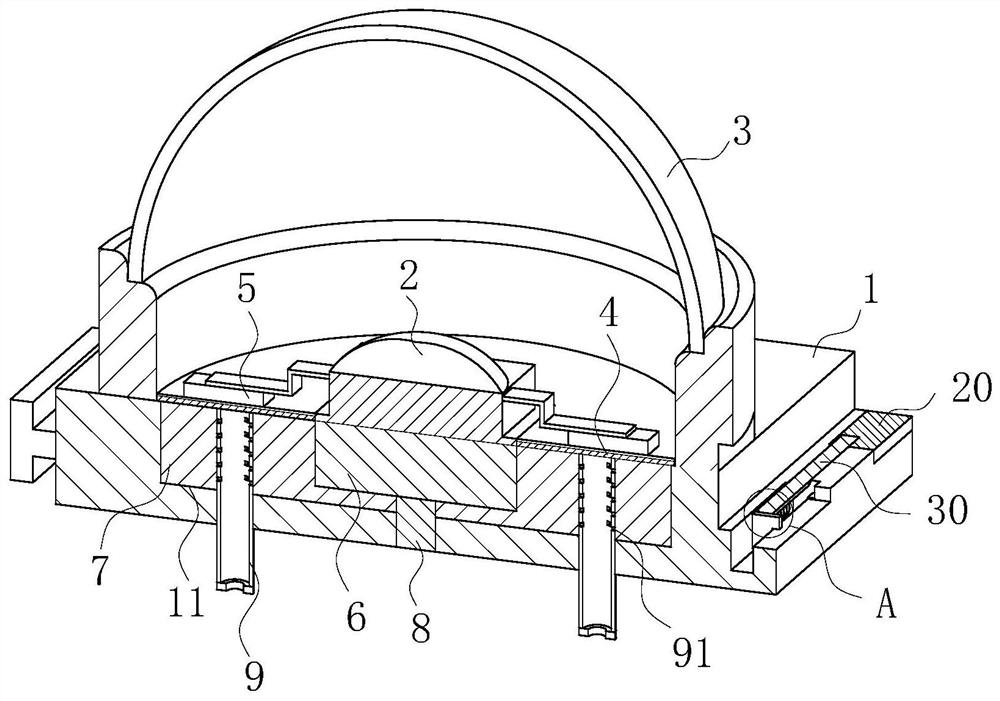

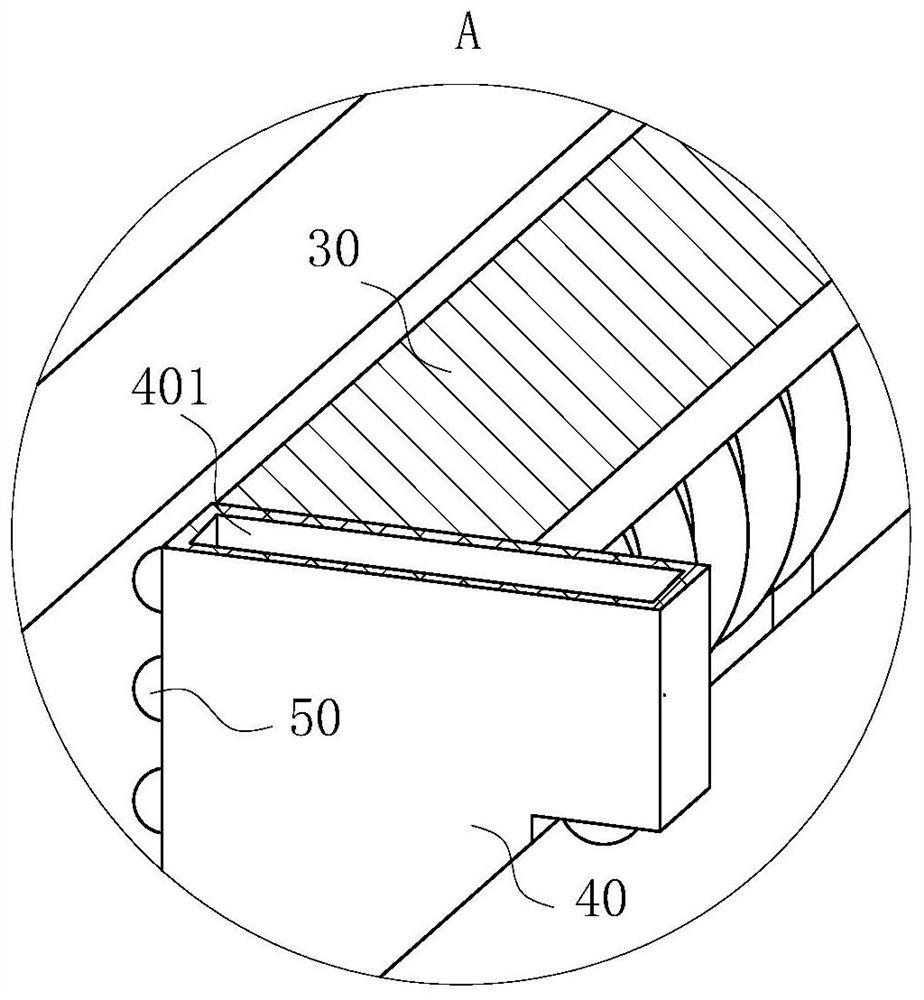

[0027] As an embodiment of the present invention, one side of the aluminum substrate 1 is provided with a T-shaped sliding groove 12, and the other side of the aluminum substrate 1 is provided with a T-shaped sliding bar 10; Porous aluminum foam material; the T-shaped slider 10 and the T-shaped slider groove are slid and mated with each other; when working, when multiple LED structures are spliced, the T-shaped slider on the side of one of the aluminum substrates 1 can be first 10 is aligned with the notch of the T-shaped chute 12 opened on the side wall of another aluminum substrate 1, and then the aluminum substrate 1 is pushed, so that the T-shaped slider 10 can be slid and inserted into the T-shaped chute 12, and then two adjacent The interconnection of multiple LED structures not only improves the stability of the interconnection of multiple LED structures, but also the T-shaped slider 10 uses through-hole foamed aluminum material, which can reduce the overall weight of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com