Milling and grinding device for eliminating upwarp diseases of railway sleepers

A technology for railway track milling and grinding, which is applied in the directions of roads, tracks, laying tracks, etc., and can solve the problems of low efficiency and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

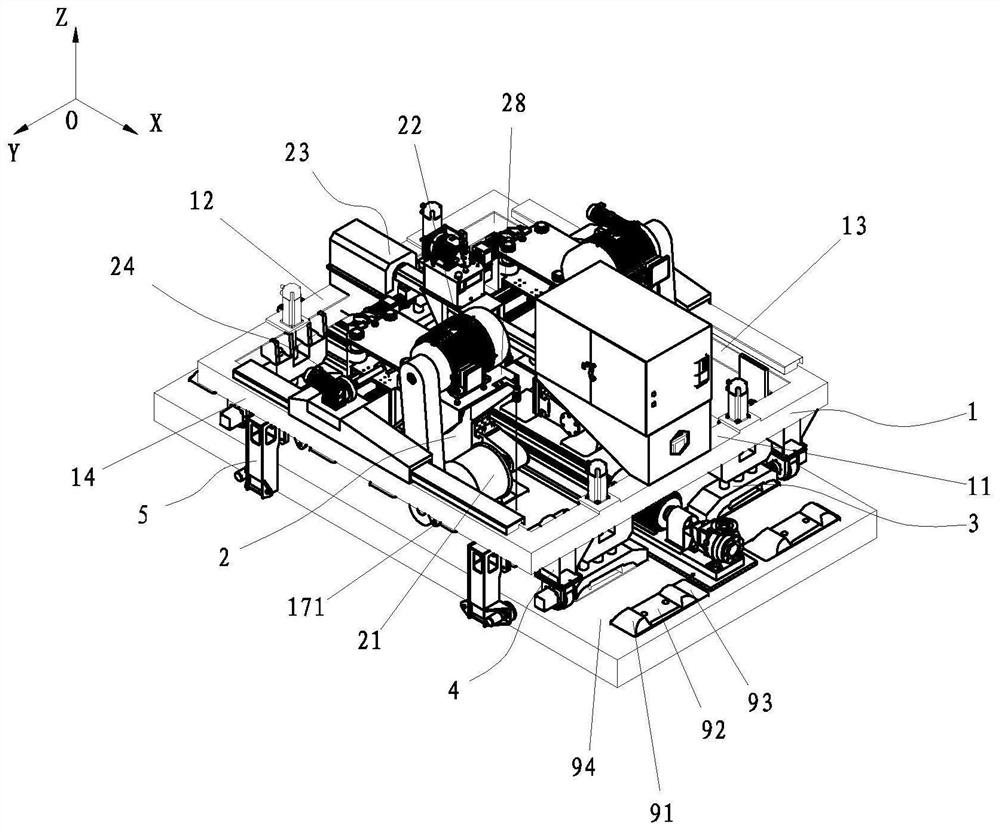

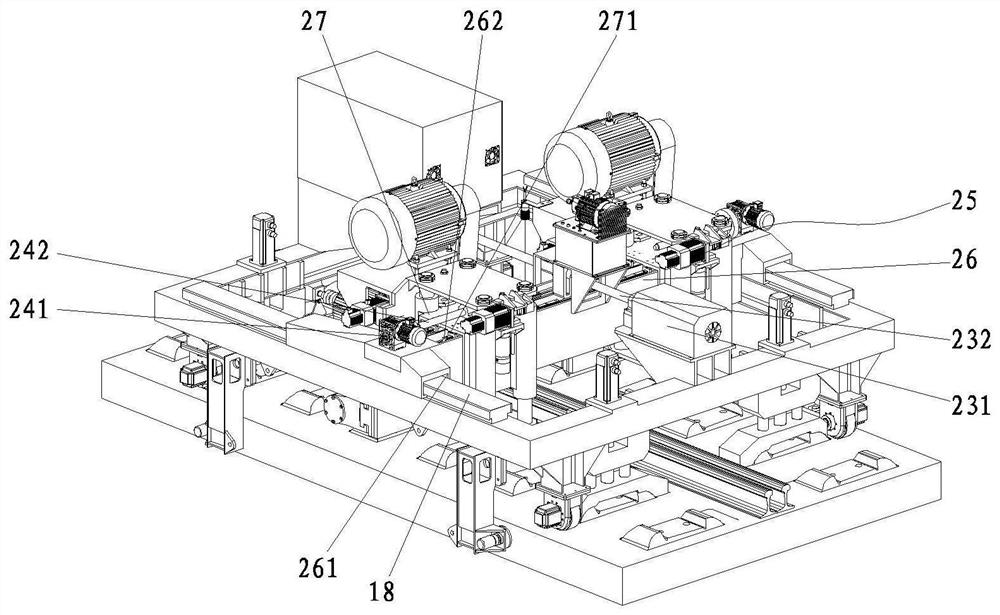

[0071] In the figure, the coordinate axes X, Y, and Z respectively represent the front-to-back direction, the left-right direction and the up-down direction of the present invention, and the coordinate axis X points to the front direction, the coordinate axis Y points to the right direction, the coordinate axis Z points to the upward direction, and the coordinate axes X, Y The intersection point of , Z is point O.

[0072] Such as Figure 1-13 As shown, a milling device for eliminating arching defects on railway sleepers, which includes a processing cutter head 21 for milling and grinding the sleeper, a cutter head rotating drive device 22 for driving the processing cutter head to run, and a device for driving the processing cutter head to move The cutter head moves the driving mechanism. Also comprise mobile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com