Sulfur-tolerant methanation system and method for coal-based natural gas

A technology for sulfur-resistant methanation and coal-to-natural gas, which is applied in chemical instruments and methods, gasification process, granular/powder fuel gasification, etc. The effect of improving the degree of methanation reaction and increasing the production load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

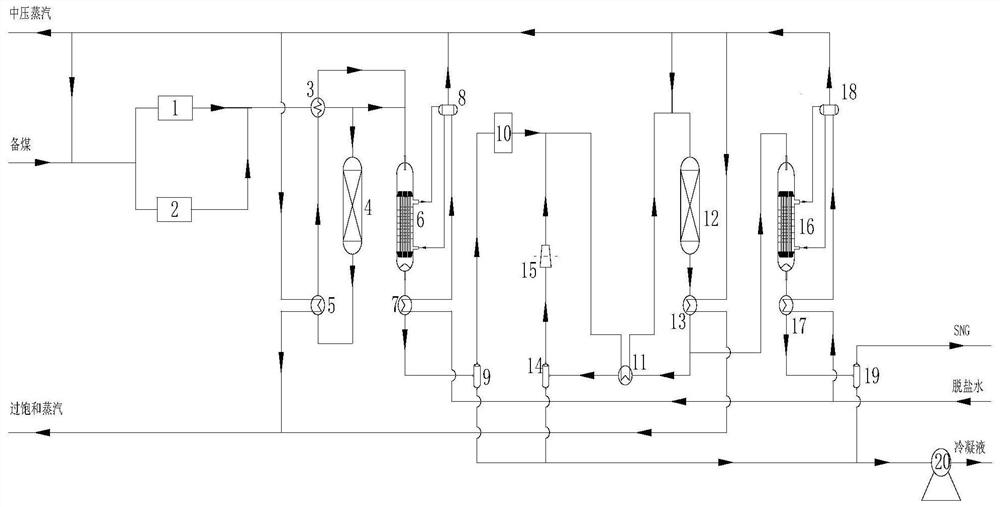

[0030] figure 1 It is the new coal-to-natural gas sulfur-resistant methanation process system of the present invention. The qualified coal particles prepared in the coal preparation section are distributed to the crushed coal gasification process 1, and the remaining pulverized coal and unqualified coal particles are processed and distributed to pulverized coal or water coal Slurry gasification process 2, the crude gas mixed pipeline generated by the two-way gasification process passes through the gas-gas heat exchanger I3 after heat exchange, and then enters the series-parallel adiabatic sulfur-resistant methanation reactor 4 and the uniform temperature sulfur-resistant methanation reactor The sulfur-resistant methanation reaction is carried out in 6, the crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com