A kind of preparation method of bio-based flame retardant and the method for preparing flame-retardant polyurethane foam

A polyurethane foam and flame retardant technology, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of poor flame retardancy, small addition, and affecting the mechanical properties of polyurethane foam, and achieve mechanical properties Balanced with flame retardant performance, excellent effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a bio-based flame retardant, comprising the following steps;

[0035] (1) After adding distilled water to the phytic acid aqueous solution with a mass fraction of 70% for dilution, continuously and slowly add sodium carbonate powder therein, after stirring evenly, until the pH value of the system is 7.0, stop adding sodium carbonate powder to obtain phytic acid Sodium aqueous solution, wherein the volume ratio of phytic acid aqueous solution and distilled water is 10:5;

[0036] (2) After mixing the tannic acid aqueous solution and ethylene glycol with a mass fraction of 5% according to the ratio of 3:1 by volume, then adding sodium phytate aqueous solution and 98% concentrated sulfuric acid aqueous solution to it , after the temperature was raised to 45°C in an oil bath, the reaction time was 3.5h, and the filter cake was repeatedly washed with distilled water for 3 times, and the white solid was collected and dried to obtain tannin phytate, ref...

Embodiment 2

[0038] A method for preparing a flame-retardant polyurethane foam with a bio-based flame retardant, comprising the following steps:

[0039](1) After mixing paraformaldehyde, ethylene glycol, melamine, and urea in a mass ratio of 1.0:2.0:3.3:1.0, raise the temperature of the mixture to 105°C, and keep it warm for 28 minutes. Add ammonium chloride, adjust the pH value of the system to 4.0, continue the reaction for 28 minutes, add diethanolamine to it, adjust the pH value of the system to 9.3, and continue the curing reaction at 80°C for 60 minutes to obtain ethylene glycol modified melamine Resin, referred to as EMF resin;

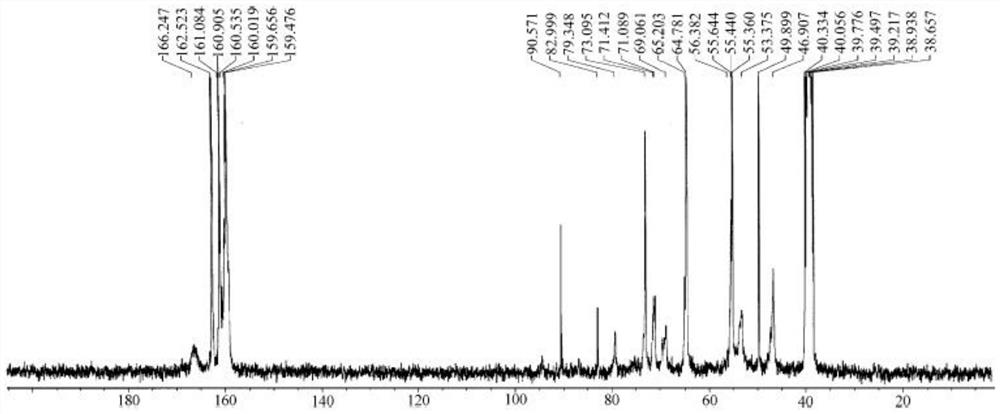

[0040] use 13 The C-NMR spectrum characterized the molecular microstructure of EMF. Such as figure 2 Shown, DMSO-d6 38.657~40.334, 46.907—NH— C h 2 —NH—, 49.899 C h 2 OH, 53.375—N(CH 2 —) — C h 2 NH—, 55.360—CO—NH C h 2 OCH 3 , 55.440—CO—N(CH 2 —) C h 2 OCH 3 , 55.644 —C=N—NHCH 2 o C h 3 (on the triazine ring), 56.382-C=N-N(CH 2 o C ...

Embodiment 3

[0044] In this example, when preparing the bio-based macromolecular intumescent flame retardant, the mass ratio of ethylene glycol-modified melamine resin to tannin phytate is 50:15, and the rest of the operation steps are exactly the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com