Constant-temperature impregnation device for composite fiber winding

A technology of dipping device and constant temperature device, which is applied in the direction of coating, etc., can solve the problems of fiber fluffing, uneven fiber dipping, insufficient fiber dipping, etc., to achieve improved fiber wear, high temperature control range accuracy, and improved The effect of quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

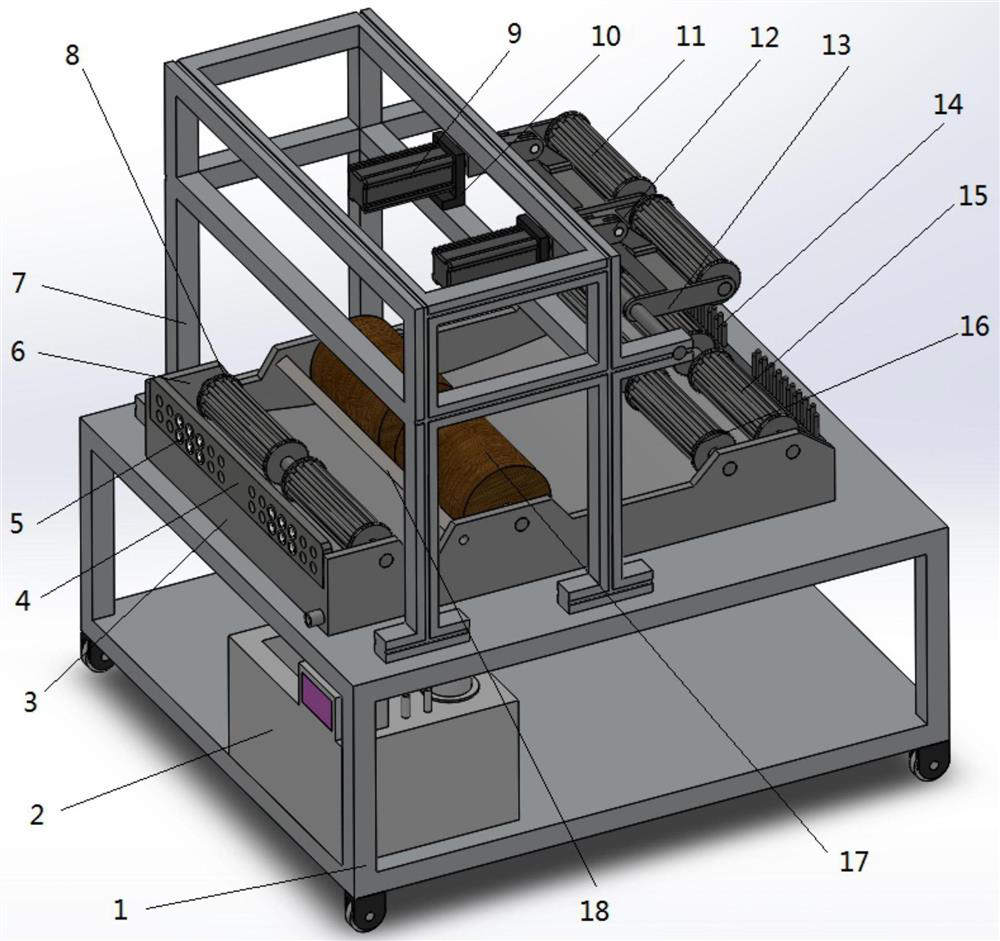

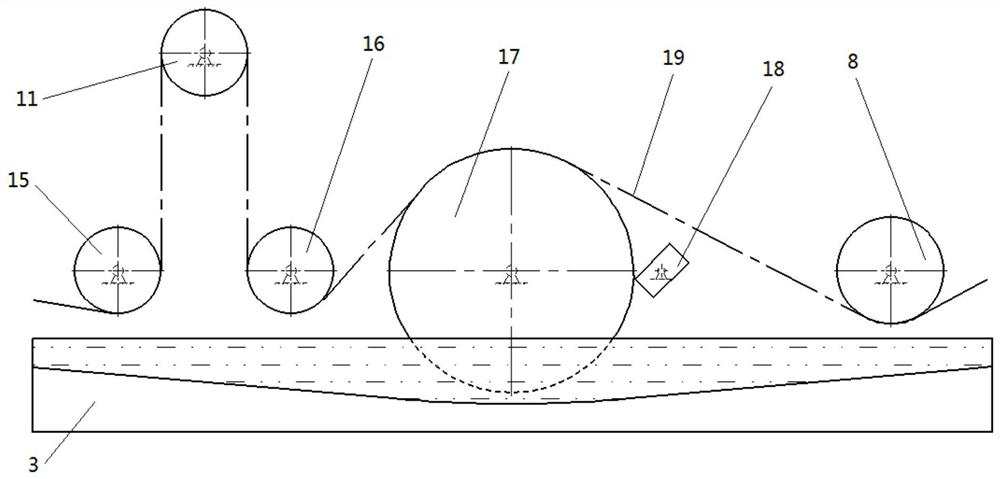

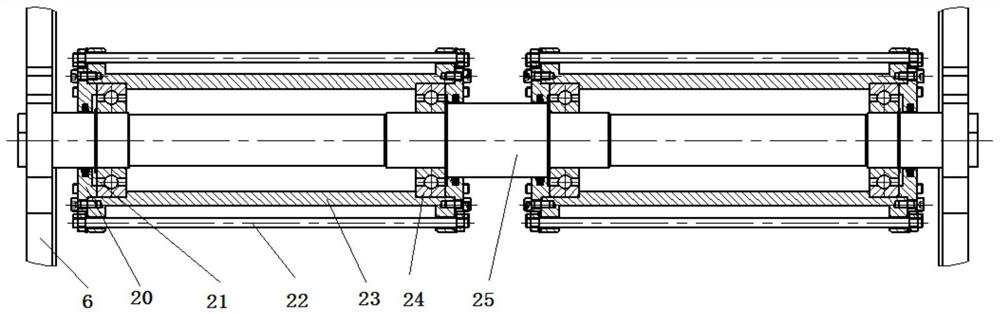

[0012] exist figure 1 and image 3 Among them, the main body of the base (1) of the dipping device is assembled from aluminum profiles, the upper part is connected with the installation panel, which is used to install the U-shaped glue tank (3), the side vertical plate (6) and the frame (7), and the lower part is connected with the installation panel , used to install the constant temperature device (2), the bottom of the base (1) is equipped with universal casters; the constant temperature device (2) uses oil or water as the heat transfer medium to heat and maintain the temperature of the glue in the U-shaped glue tank (3) Control, there is a water outlet and a return port on it, which are respectively connected to the water inlet and drain of the U-shaped rubber tank (3), and the medium is always in the cavity below the constant temperature device (2) and the U-shaped rubber tank (3) The inside is in a flowing state, and the constant temperature device (2) is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com