Welding method of novel high alloy austenitic heat-resistant stainless steel

A heat-resistant stainless steel, welding method technology, applied in welding equipment, welding accessories, welding/welding/cutting items, etc., can solve the problems of welding hot cracks and low mechanical properties of welded joints, achieve excellent molding, and ensure welding work efficiency , to avoid the effect of excessive heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

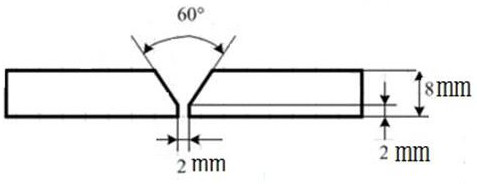

Image

Examples

Embodiment 1

[0031] In the second pass, the current is 180A, the voltage is 18.0V, the welding speed is 0.22m / min, and the heat input is 0.707 KJ / mm;

[0032] According to the national standard GB / T2651-2008 "Welded Joint Tensile Test Method", the welded joint sample of the present invention is processed into a standard tensile test sample, and the tensile test is carried out. The yield strength is ≥ 306 Mpa, and the tensile strength is ≥ 561 Mpa.

Embodiment 2

[0034] For the second pass, the current is 180A, the voltage is 18.0V, the welding speed is 0.25m / min, and the heat input is 0.622 KJ / mm;

[0035] According to the national standard GB / T2651-2008 "Welded Joint Tensile Test Method", the welded joint sample of the present invention is processed into a standard tensile sample, and the tensile test is carried out. The yield strength is ≥ 324 Mpa, and the tensile strength is ≥ 583 Mpa.

Embodiment 3

[0037] In the second pass, the current is 180A, the voltage is 18.0V, the welding speed is 0.3m / min, and the heat input is 0.518KJ / mm;

[0038] According to the national standard GB / T2651-2008 "Welded Joint Tensile Test Method", the welded joint sample of the present invention is processed into a standard tensile sample, and the tensile test is carried out. The yield strength is ≥ 313 Mpa, and the tensile strength is ≥ 573 Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com