Rotating disc type automatic flame welding machine and welding method thereof

A turntable and flame technology, applied in the direction of gas flame welding equipment, welding equipment, welding equipment, etc., can solve the problems of cumbersome operation, virtual welding, and inability to guarantee welding accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

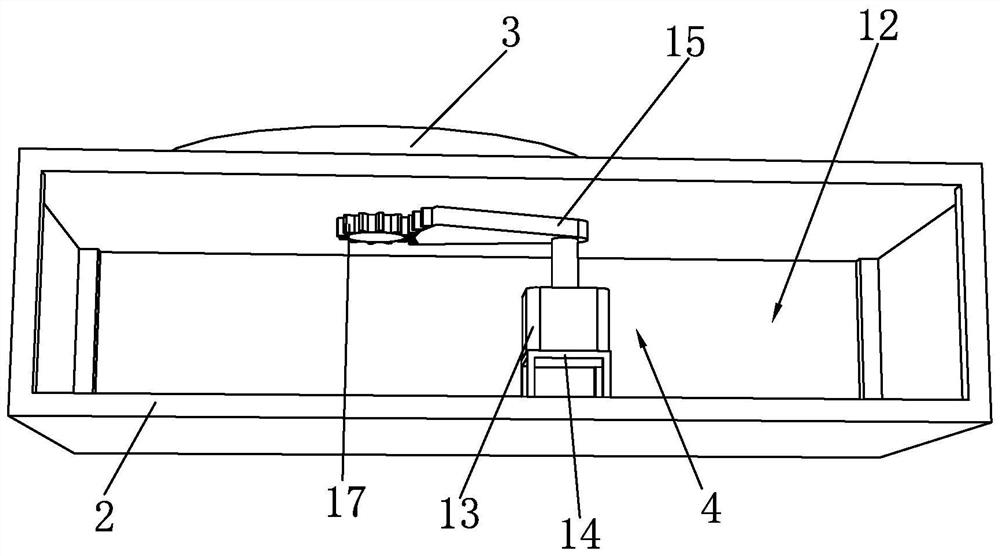

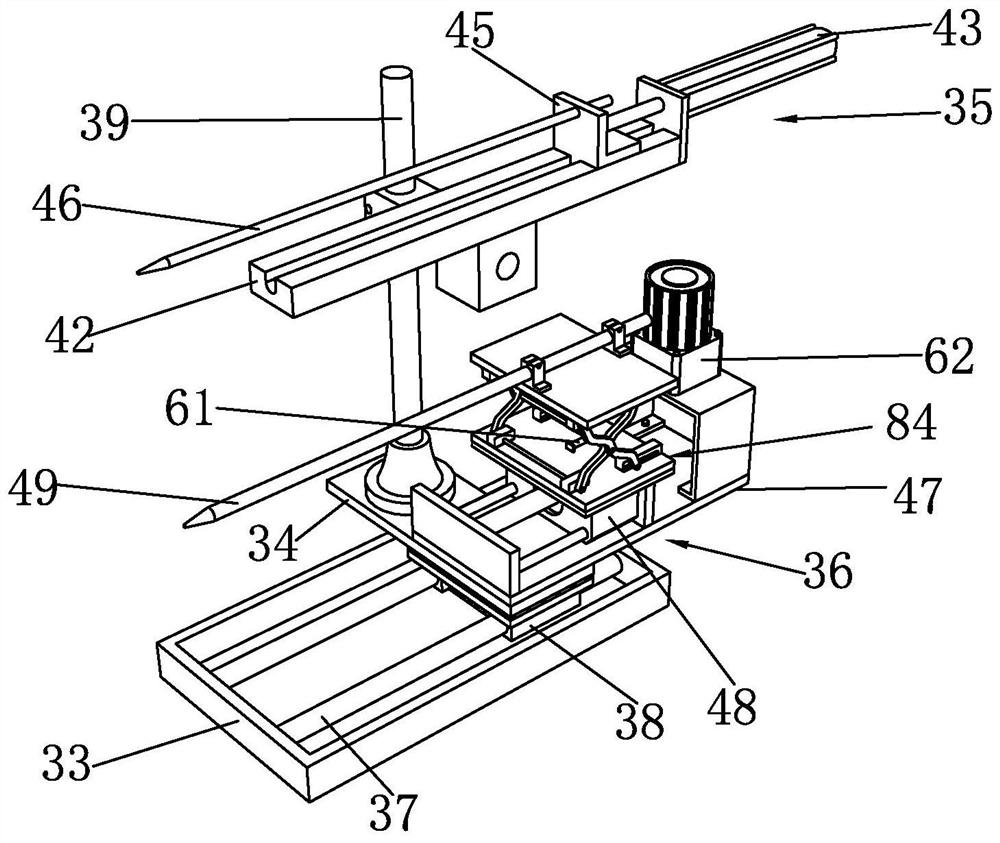

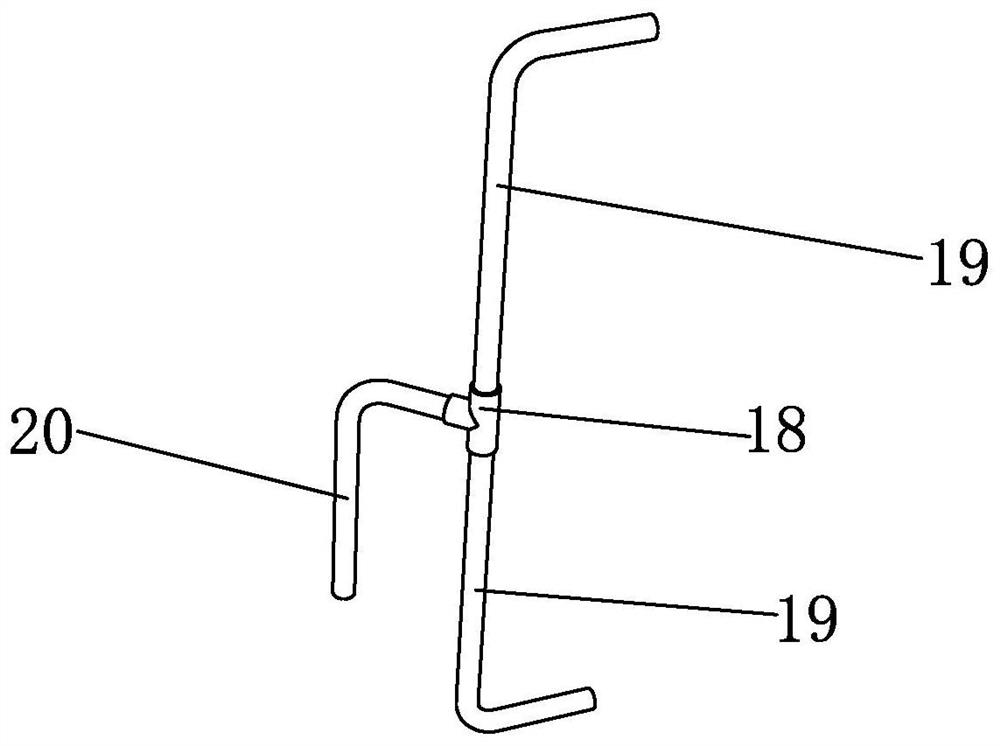

[0041] Such as Figure 1 to Figure 7 Shown is a turntable type automatic flame welding machine of the present invention, including a body 1, a welding frame 2 is provided on the body 1, a turntable 3 is provided on the top of the welding frame 2, and a driving assembly 4 is provided on the bottom of the welding frame. The turntable 3 is driven to rotate. The welding frame 2 is located on one side of the turntable 3 with a feeding device 5, and the other side of the welding frame 2 is provided with a welding device 6. The turntable 3 corresponds to the feeding device 5 and the welding device 6 with evenly arranged clamping devices Device 7, the loading device 5 transports the workpiece 8 to the clamping device 7 for clamping, the welding device 6 welds the workpiece 8 on the clamping device 7, and the clamping device 7 is provided with a clamping frame 9 and a clamping frame 9 There is a high-speed precision cam divider 10 on the top of the high-speed precision cam divider 10, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com