Improved rebar straightening frame

A straightening frame and improved technology, applied in the field of improved steel bar straightening frame, can solve the problems of large straightening centrifugal force, low production efficiency, and deformation of the straightening frame, and achieve the improvement of concentricity and rotational speed, sealing and dustproofing. Good effect, the effect of preventing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

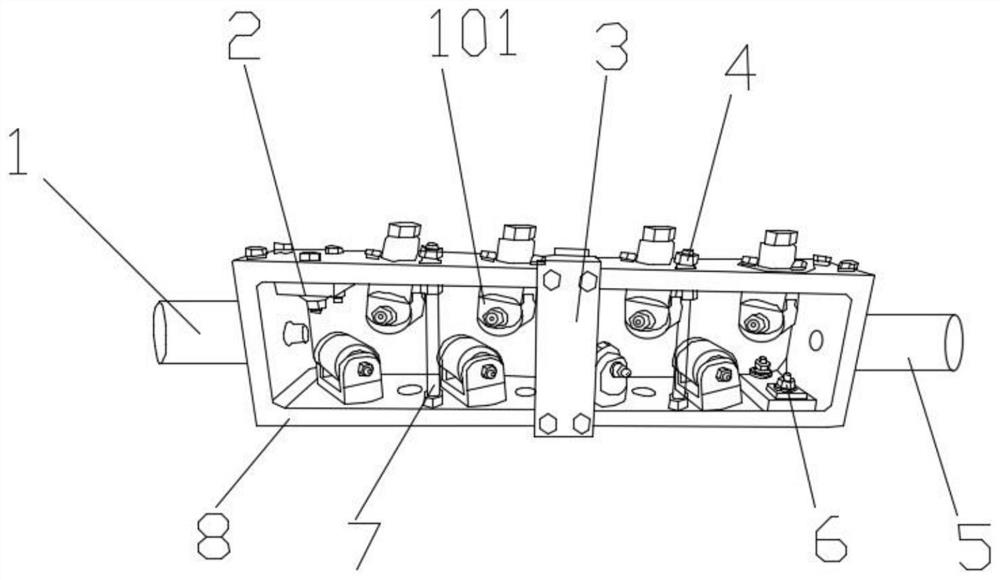

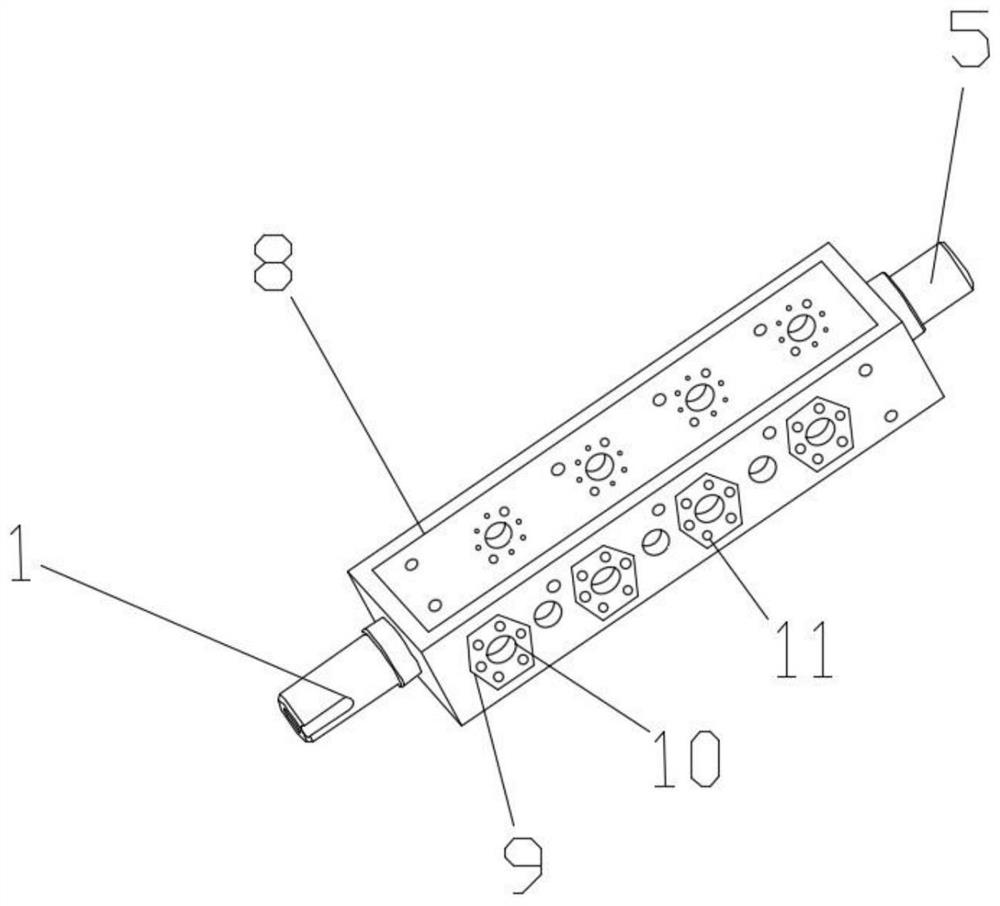

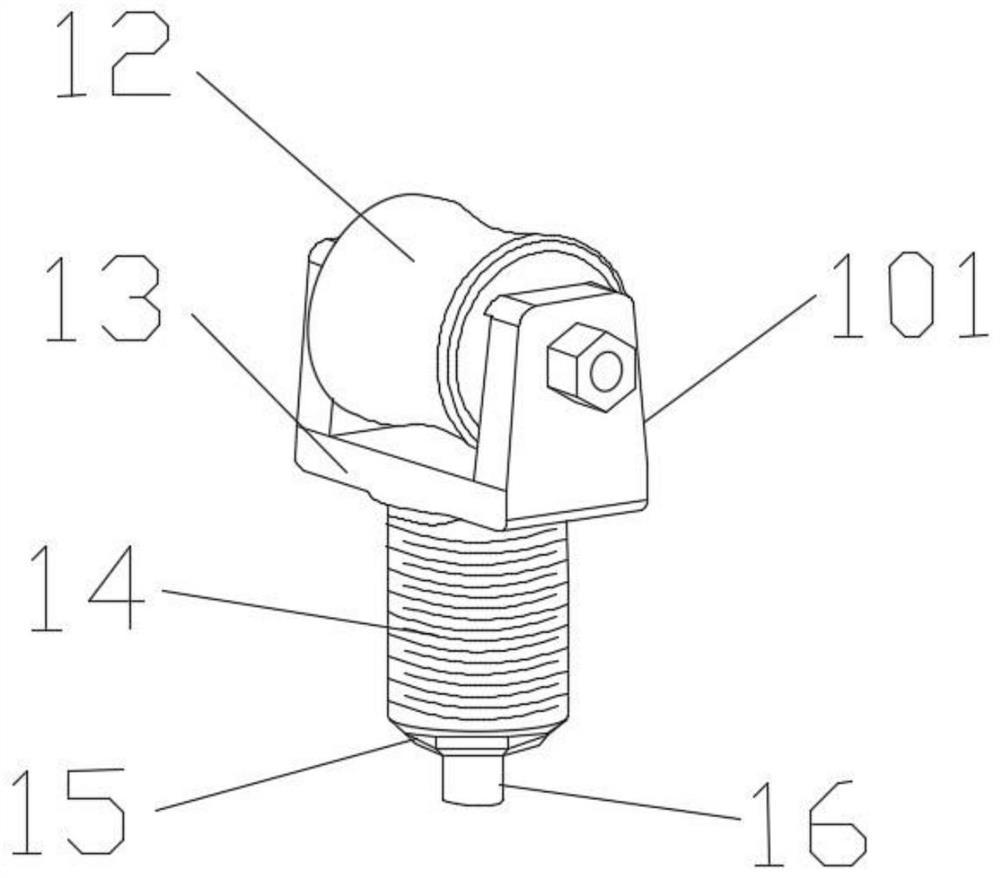

[0028] An improved steel bar straightening frame, including a first connecting pipe 1, a straightening frame body 8, a second connecting pipe 5, a straightening wheel device 101, a reinforcing platen 3, a fixing rod 7, and a milling disc 9, the described The straightening frame frame body 8 is a rectangular frame body with a hollow inside, and the two ends of the narrow side are respectively connected with the first connecting pipe 1 and the second connecting pipe 5; the straightening wheel device 101 is installed in the The inner sides of the frame body 8 of the straightening frame; the reinforcing plate 3 is fixedly installed on both sides of the frame body 8 of the straightening frame; the fixed rod 7 communicates with the frame body 8 of the straightening frame, and is fixedly installed on the On the straightening frame body 8; the milling disk 9 is hexagonal, embedded in the side of the straightening frame body 8, and the inside is provided with a milling disk groove 10 an...

Embodiment 2

[0038] In this embodiment, the main structure of the straightening frame body 8 is the same as that in Embodiment 1, the difference is that a bearing 17 or a gasket 18 is engaged in the inner groove of the wheel cavity on both sides of the straightening wheel 12, and the adjustment There are two bearings 17 or sealing pads 18 engaged on both sides of the straight wheel 12, and the bearings 17 and the sealing pads 18 have the same size and can be replaced with each other. The straightening wheel 12 is fixedly installed on the straightening wheel fixing frame 13 through the screw rod 19; the sealing gasket 18 is cylindrical, the center of the circle is provided with a round hole matching the size of the screw rod 19, and the outer side of the cylinder is provided with a concave groove; the screw rod One end of 19 is provided with an engaging part 21 for clamping with the gasket 18, and the other end is provided with a screw thread to cooperate with the nut; the diameter of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com