Oxygen-deficient molybdenum oxide/nickel sulfide/foamed nickel electrocatalyst and preparation method thereof

An electrocatalyst, nickel sulfide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., to achieve excellent catalytic hydrogen evolution activity, improve hydrogen evolution reaction performance, and enhance electrical conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

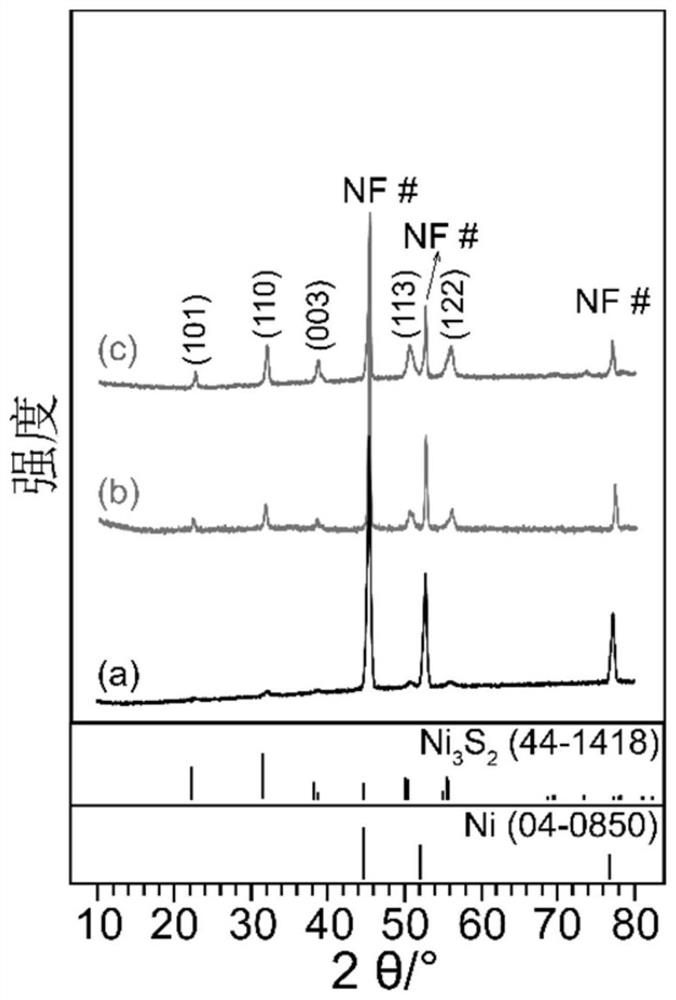

[0043] The invention provides a method for preparing an oxygen-deficient molybdenum oxide / nickel sulfide / nickel foam electrocatalyst, comprising the following steps:

[0044] Prepare 0.05-0.1mol / L molybdenum-containing compound solution, the solvent is selected from the composition of ethanol and water, wherein the volume ratio of ethanol and water is 1-2:1, and the molybdenum-containing compound is selected from sodium molybdate or molybdenum ammonium acid.

[0045] A sulfur-containing compound is added so that the molar ratio of molybdenum to sulfur is 1:4˜1:6, and the sulfur-containing compound is selected from thiourea or sodium thiosulfate.

[0046]Excessive nickel foam is added, hydrothermal reaction is carried out at 135-145° C. for 16-24 hours, and the oxygen-deficient molybdenum oxide / nickel sulfide / nickel foam electrocatalyst is obtained after cooling to room temperature.

[0047] The present invention is not particularly limited to molybdenum-containing compound, a...

Embodiment 1

[0063]

[0064] 0.483g (2.0mmol) sodium molybdate Na 2 MoO 4 2H 2 O was dissolved in a mixed solution composed of ethanol and deionized water, and the molybdenum-containing compound solution was obtained after magnetic stirring for 30 minutes. mol / L;

[0065] 0.760g (10mmol) thiourea CH 4 N 2 S was added to the molybdenum-containing compound solution, and magnetically stirred for 30 minutes to obtain a precursor solution, so that the molar ratio of molybdenum to sulfur was 1:5.

[0066]

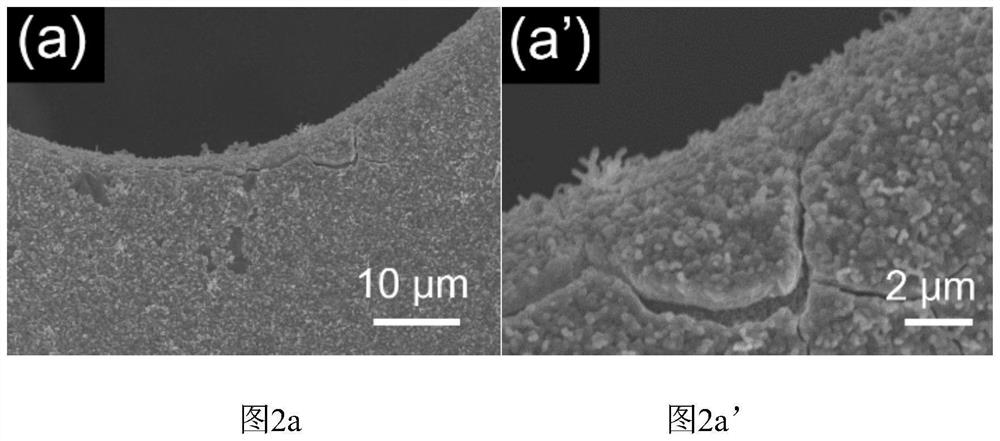

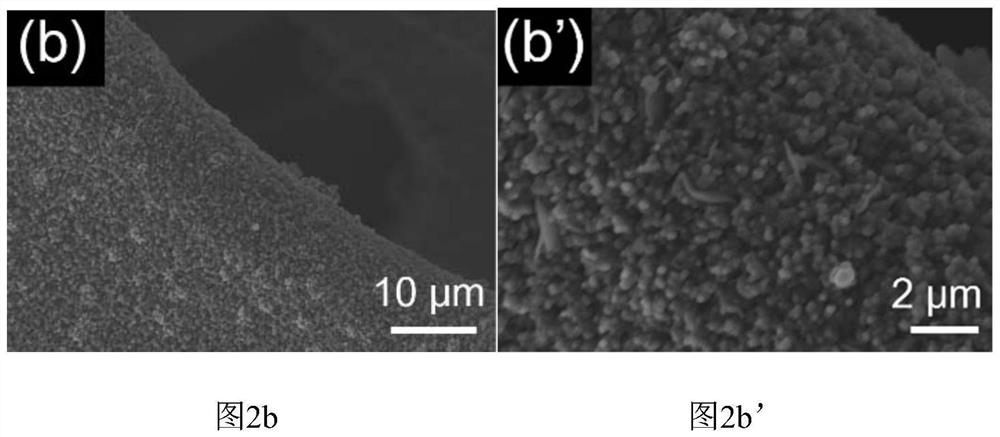

[0067] Put two pieces of 1×2cm pretreated nickel foam and precursor solution into a stainless steel hydrothermal reaction kettle lined with polytetrafluoroethylene, hydrothermally react at 140°C for 18h, and cool to room temperature to obtain the reaction product.

[0068]

[0069] The reaction product oxygen-deficient molybdenum oxide / nickel sulfide / nickel foam was washed three times with deionized water and ethanol, and then dried at 50°C for 12 hours to obtain dry oxygen-defici...

Embodiment 2

[0072] Except that the volume ratio of ethanol and water is 2:1, the rest is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com