Oil tank capable of realizing scrap-removing and cleaning

A fuel tank cleaning technology, which is applied in the field of hydraulic system fuel tanks, can solve problems such as doping, and achieve the effect of avoiding oil ingress and maintaining oil cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

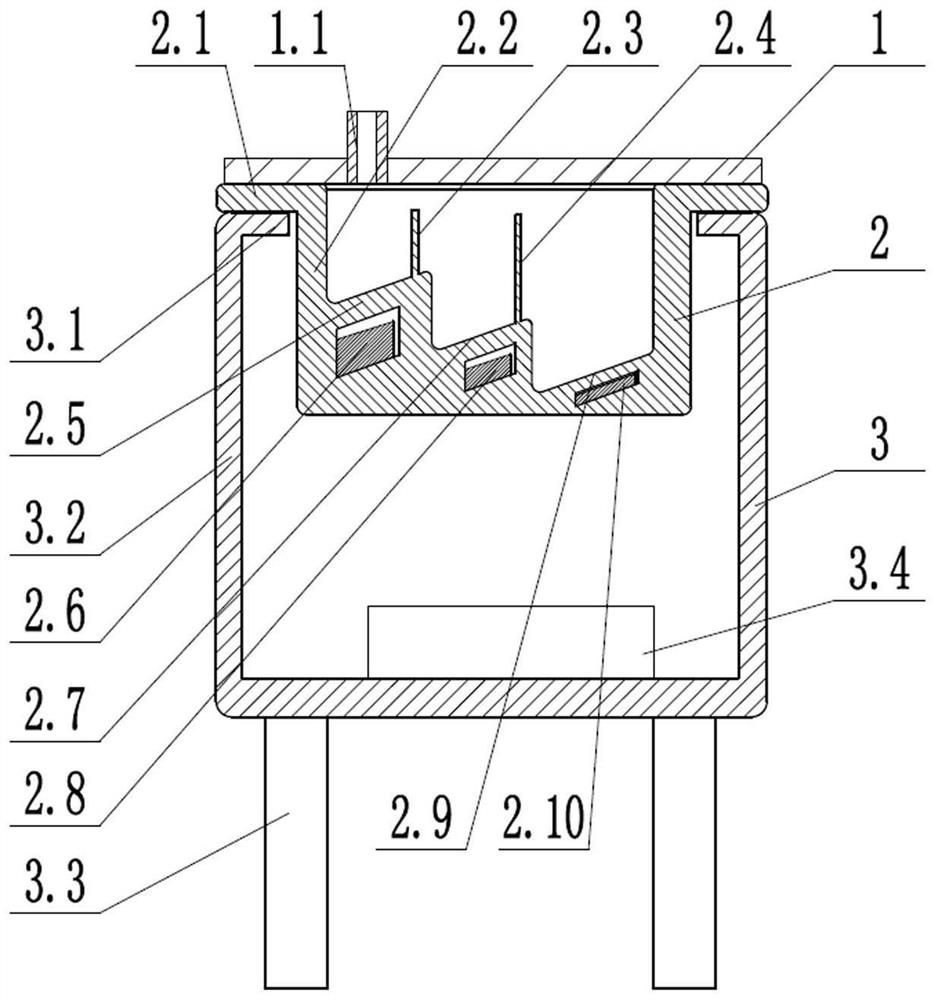

[0031] like Figure 1 to Figure 4 As shown, the cleaning oil tank for removing debris according to the present invention includes an inner oil tank 2 and an outer oil tank 3, the inner oil tank 2 is set on the upper part of the outer oil tank 3, and the upper part of the inner oil tank 2 is provided with an end cover 1.

[0032] in:

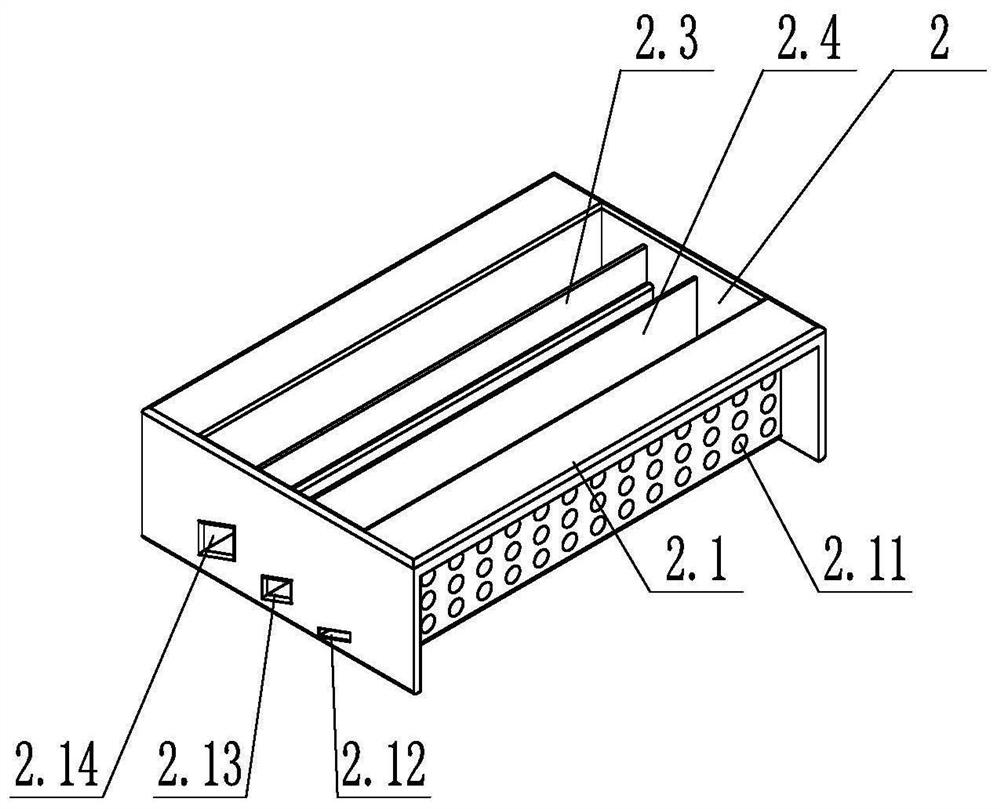

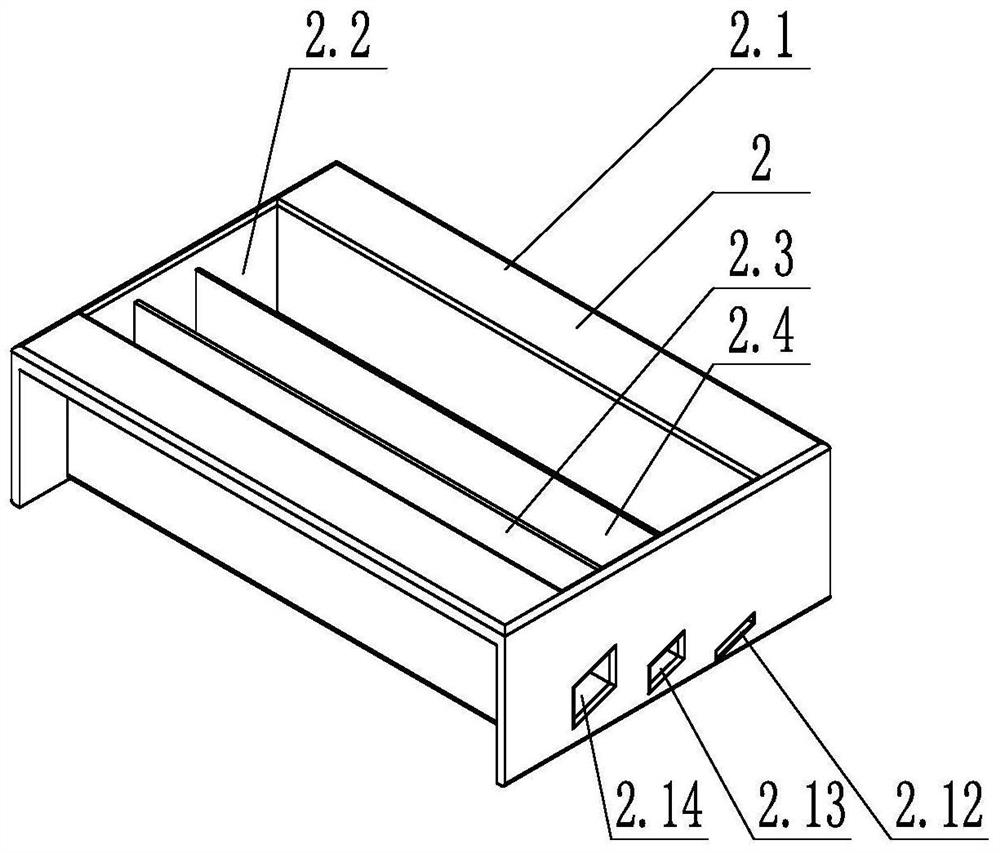

[0033] The inner oil tank 2 includes an inner oil tank body 2.2, and an outer frame plate 2.1 is provided on both sides of the top of the inner oil tank body 2.2, and a filter step is provided on the inner bottom of the inner oil tank body 2.2, and a filter step is provided on the inner oil tank body 2.2 on the other side of the filter step. Oil hole 2.11; a storage tank is provided below the filter step, a magnet is arranged in the storage tank, and the storage tank is not connected with the inner cavity of the inner oil tank; a filter screen can be provided on the filter step. Both ends of the accommodating tank are provided with plugs. Filte...

Embodiment 2

[0038] like figure 1 As shown, the filter steps include a first filter step 2.5, a second filter step 2.7 and a third filter step 2.9, the first filter step has an upward inclination angle of 20° relative to the horizontal line, and the second filter step has an upward inclination angle of 20° relative to the horizontal line. The third filter step has an upward inclination angle of 35° relative to the horizontal line. All the other are with embodiment 1.

Embodiment 3

[0040] like figure 1 As shown, the filter steps include a first filter step 2.5, a second filter step 2.7 and a third filter step 2.9, the first filter step has an upward inclination angle of 15° relative to the horizontal line, and the second filter step has an upward inclination angle of 25° relative to the horizontal line. The third filter step has an upward inclination angle of 30° relative to the horizontal line. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com