Layered disinfection cabinet

A technology of disinfection cabinet and disinfection chamber, which is used in disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of inability to switch between upper and lower disinfection modes, high cost, and occupation of disinfection space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

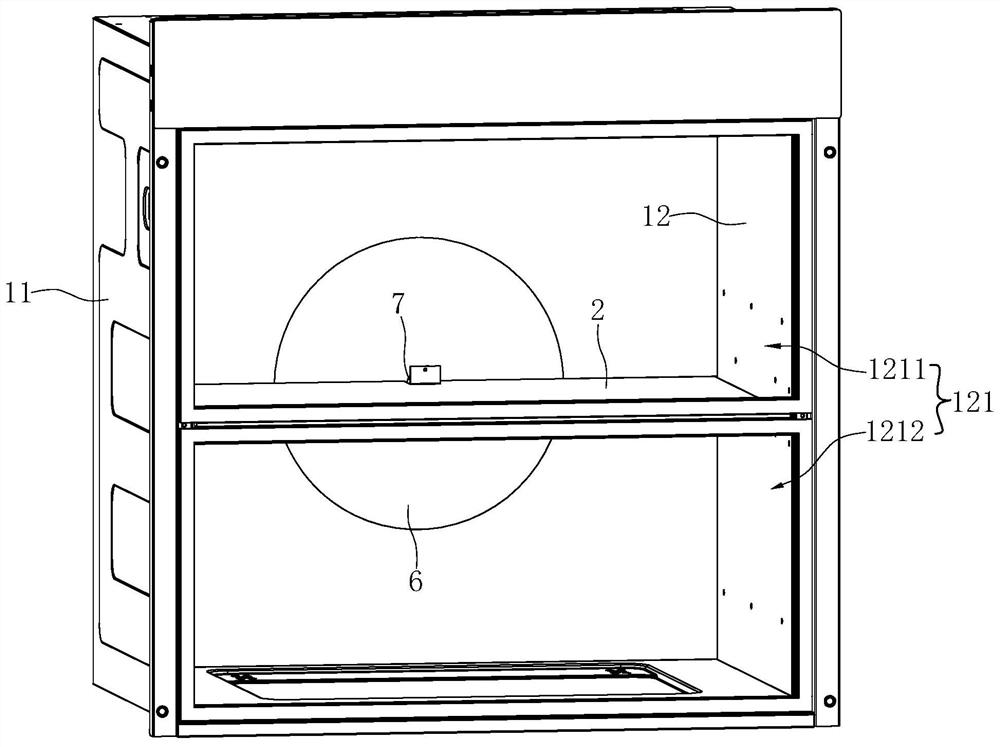

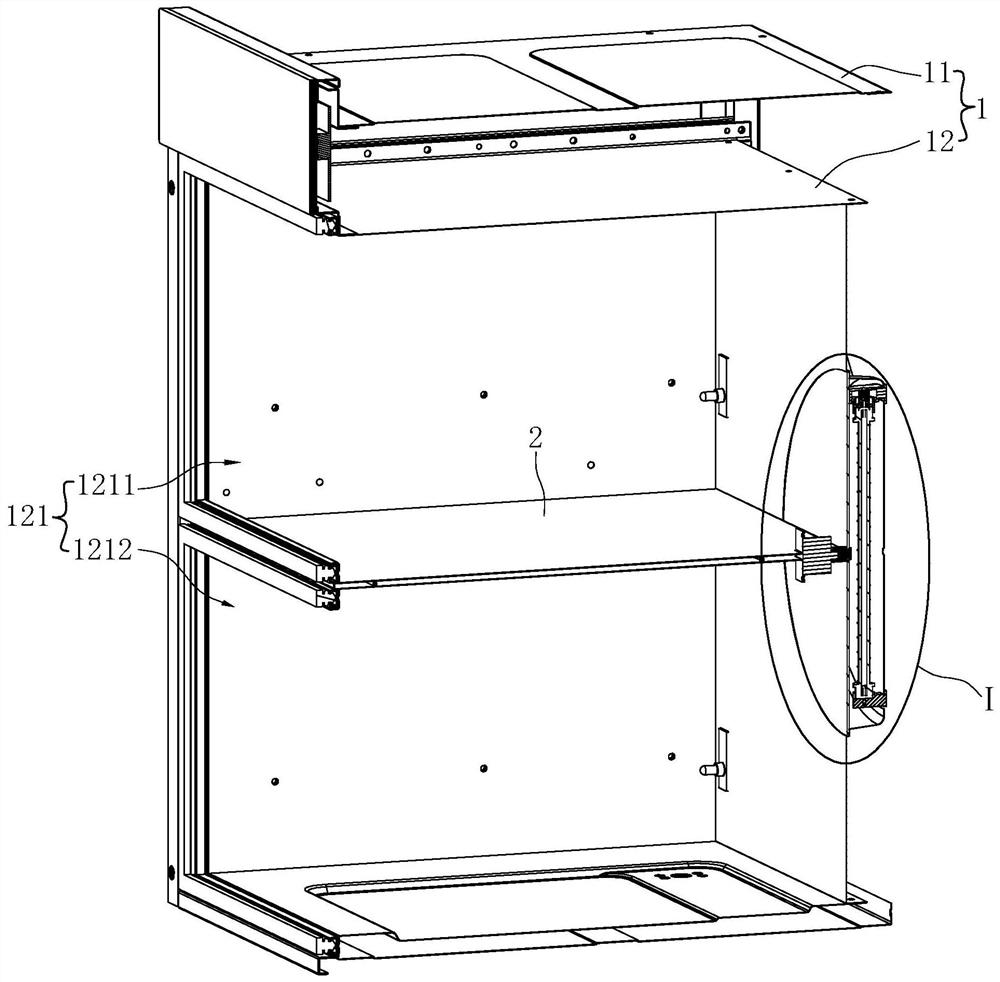

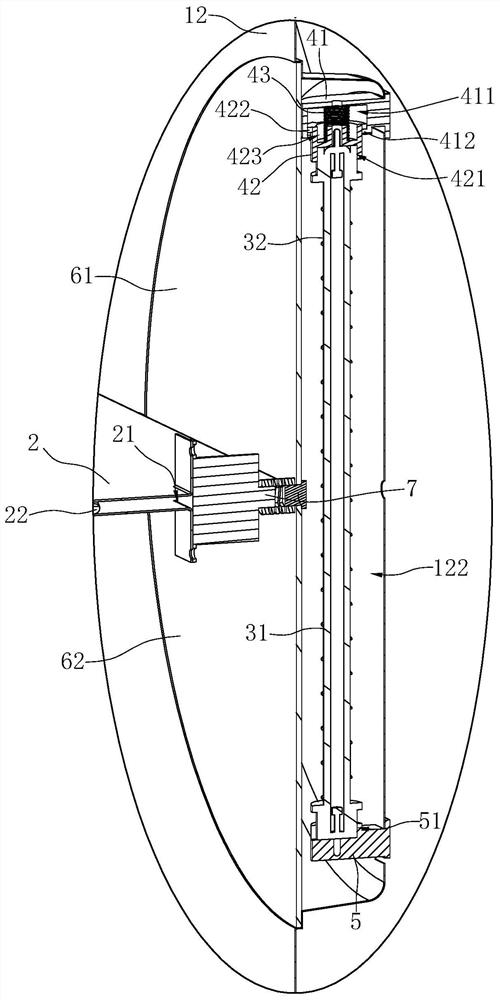

[0040] Such as Figure 1 to Figure 7 Shown is the first preferred embodiment of the layered disinfection cabinet of the present invention. The layered disinfection cabinet includes a cabinet body 1 , a partition plate 2 , a lamp tube 3 , a first lamp holder 4 , a second lamp holder 5 , a light filter cover 6 and a first driving member 7 .

[0041] Wherein, the cabinet body 1 includes an outer shell 11 and an inner tank 12 arranged in the outer shell 11. The inner tank 12 has a disinfection chamber 121, and the rear side wall of the inner tank 12 is partially recessed outward to form a recessed portion 122. The opening of the recessed portion 122 is marked as the first installation opening 1221 .

[0042] The partition plate 2 is arranged substantially horizontally in the middle of the disinfection chamber 121 , and divides the disinfection chamber 121 into a first chamber 1211 located above and a second chamber 1212 located below. The rear part of the partition plate 2 is pr...

Embodiment 2

[0057] Such as Figure 7 to Figure 9 Shown is the second preferred embodiment of the layered disinfection cabinet of the present invention. The difference with Example 1 is:

[0058] In this embodiment, a beam splitter 8 and a second driving member 9 are added.

[0059] Wherein, the reflector 8 is located in the above-mentioned recessed portion 122 , and the above-mentioned lamp tube 3 is located between the light filter cover 6 and the reflector 8 arranged side by side. In this embodiment, the side wall of the side wall of the reflector 8 facing away from the lamp tube 3 is partially pressed inward to form a plurality of bosses 81 arranged at intervals. The direction of the lamp tube 3 gradually decreases, and the side wall of the side wall of the reflector 8 facing the lamp tube 3 is partially pressed outward to form a plurality of grooves 82 arranged at intervals. It gradually decreases toward the direction of the lamp tube 3, thereby diffusely reflecting the pulse flash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com