Efficient inflator pump

An air pump, high-efficiency technology, used in pumps, pump control, piston pumps, etc., can solve the problems of poor work continuity, long inflation time, low work efficiency, etc., to avoid wear, improve inflation efficiency, and improve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

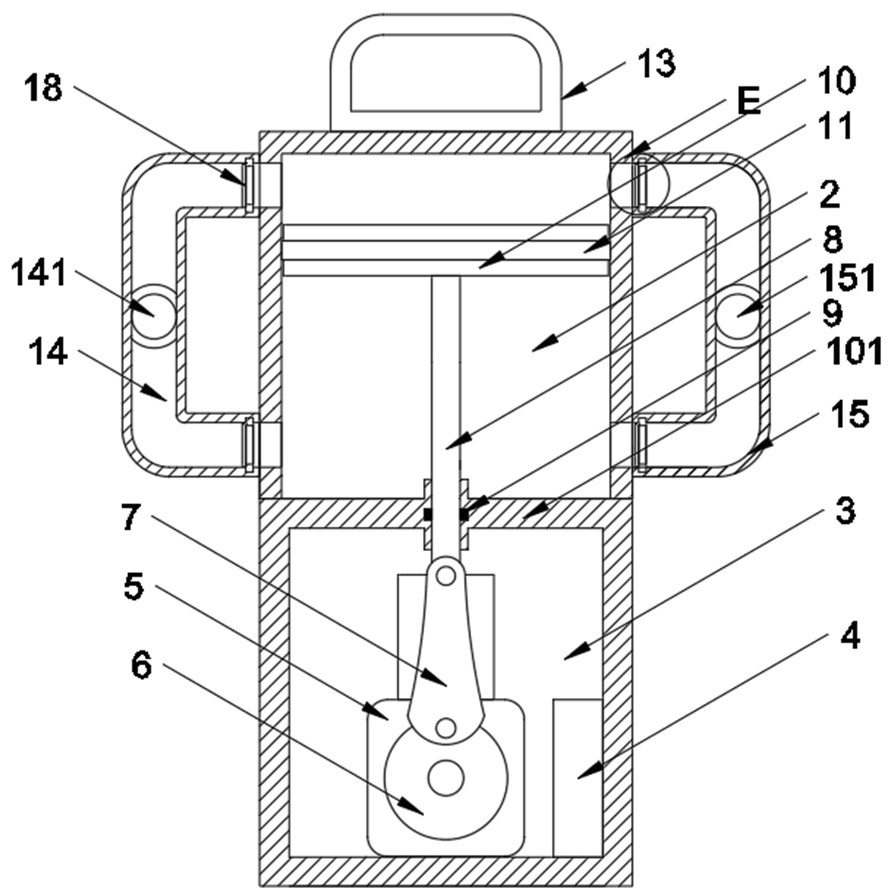

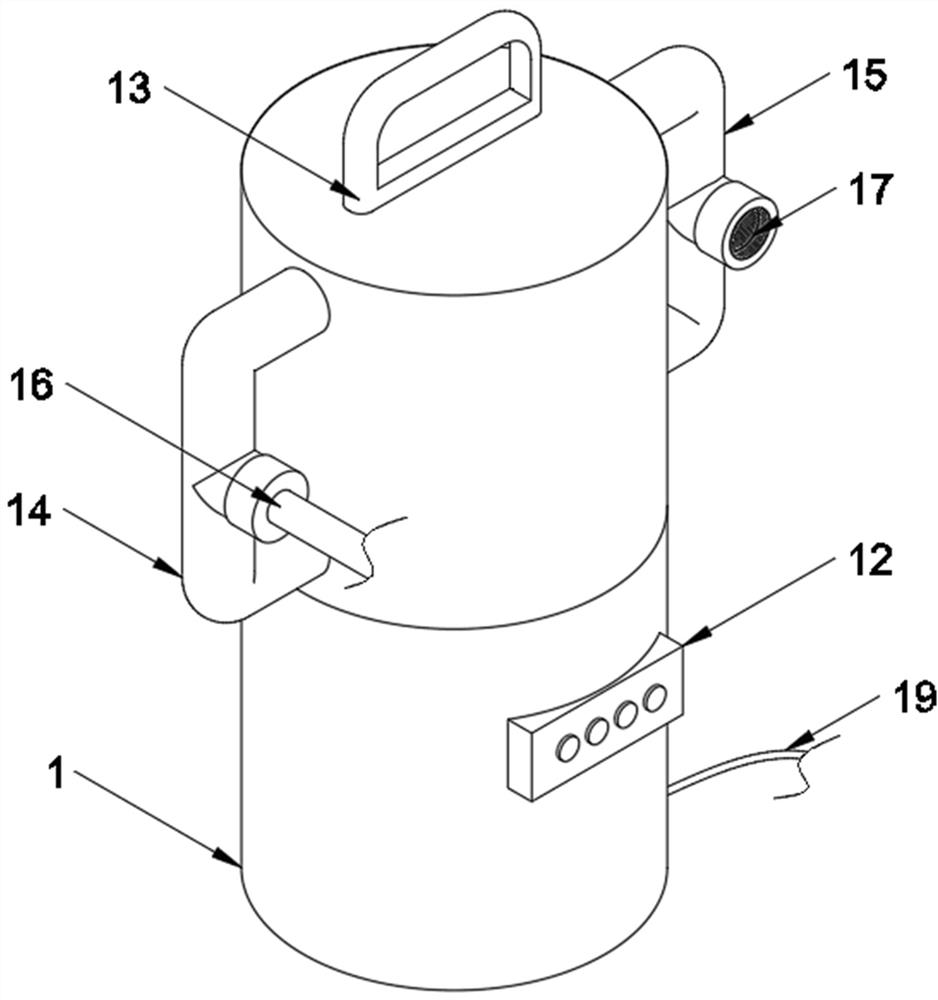

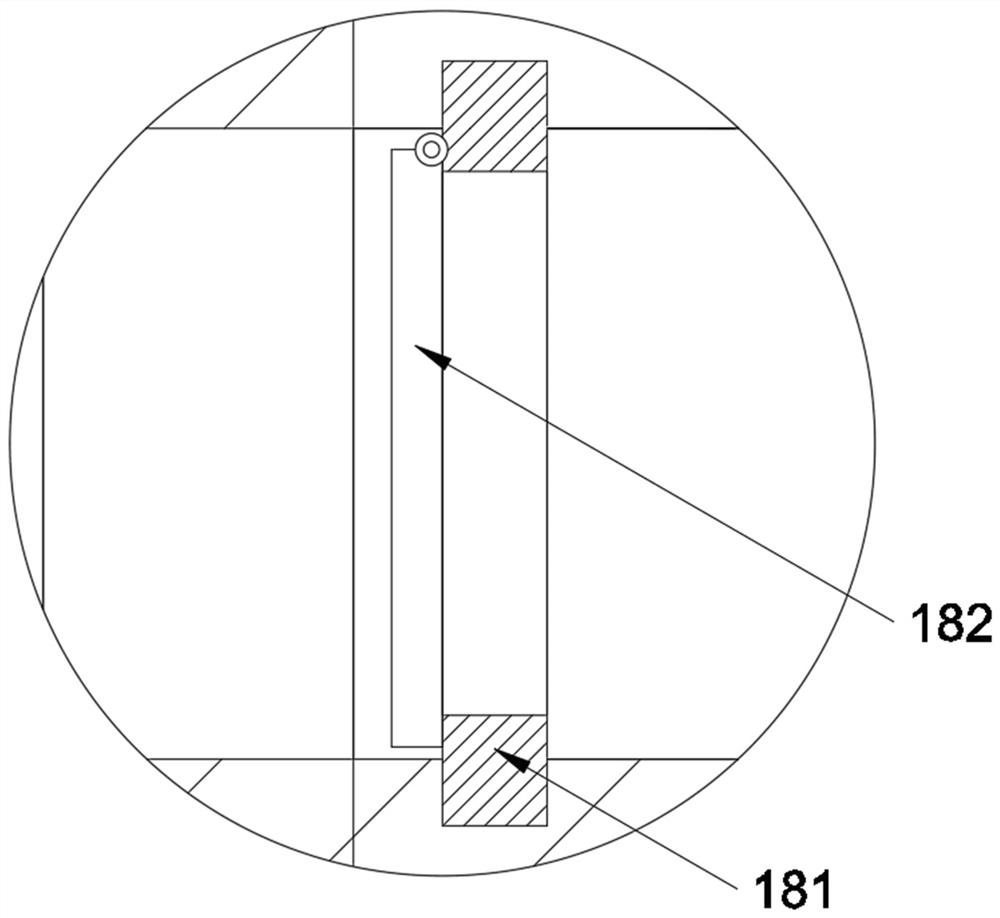

[0024] see Figure 1-Figure 5 , the present invention provides the following technical solutions: a high-efficiency air pump, including a housing 1, a handle 13 is fixedly installed on the top surface of the housing 1, and a control box 12 is fixedly installed on the front side of the housing 1, so The inner side of the housing 1 is divided into a compression compartment 2 and an electrical compartment 3 through a compartment plate 101. The bottom of the electrical compartment 3 is fixedly installed with a switching power supply 4 and a brushless DC motor 5, and the switching power supply 4 is fixedly connected to a power cord. 19. The output shaft of the brushless DC motor 5 is fixedly connected with a runner 6, the side of the runner 6 is eccentrically installed with a connecting rod 7, and the top end of the connecting rod 7 is fixedly connected with a piston 10, and the piston 10 A piston sealing ring 11 is fixedly installed on the side of the compression chamber 2, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com