Slide rail type multi-level vertical wind power generation device

A technology of wind power generation device and slide rail, which is applied in wind power generation, wind power generator, wind power generator at right angles to the wind direction, etc. It can solve the problems of difficult installation, large centrifugal force, easy to be blown over, etc., so as to increase the weight of the device, occupy Small ground area, enhanced effect of wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

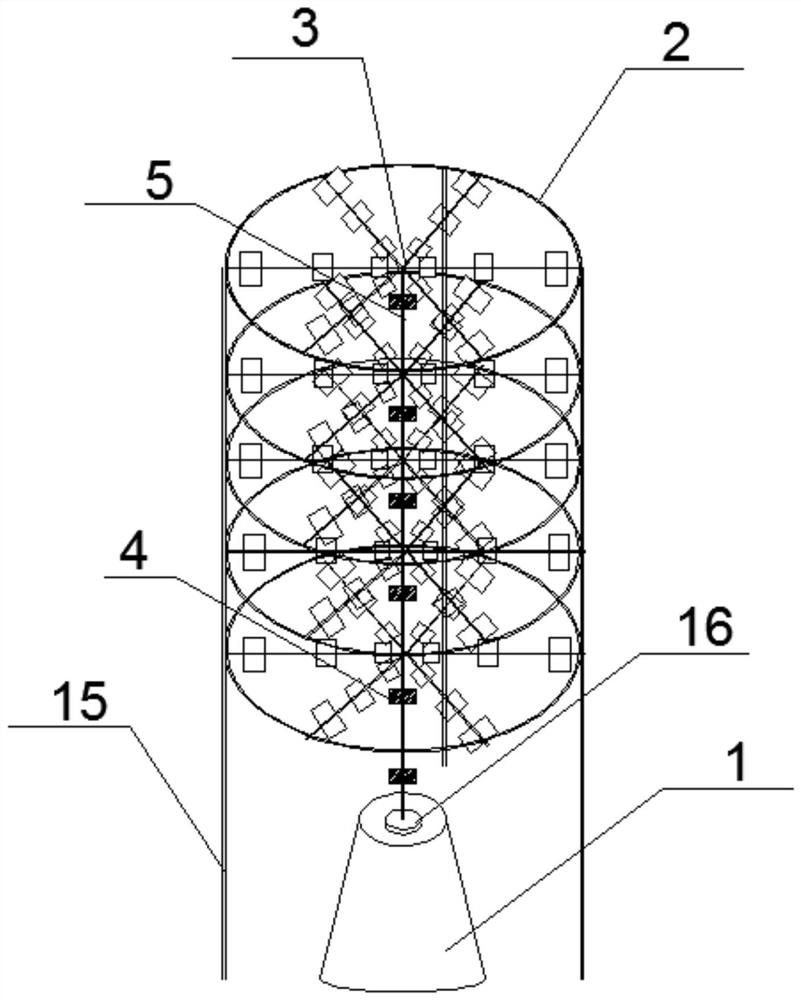

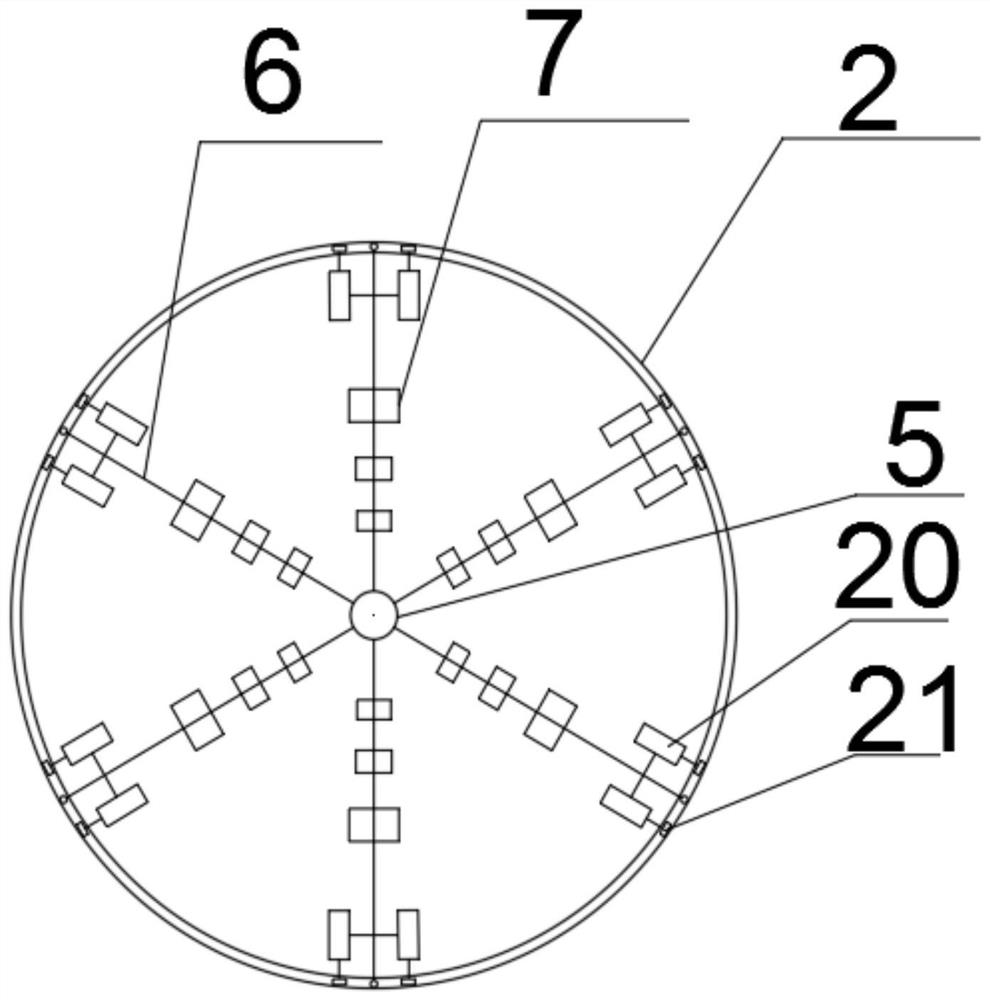

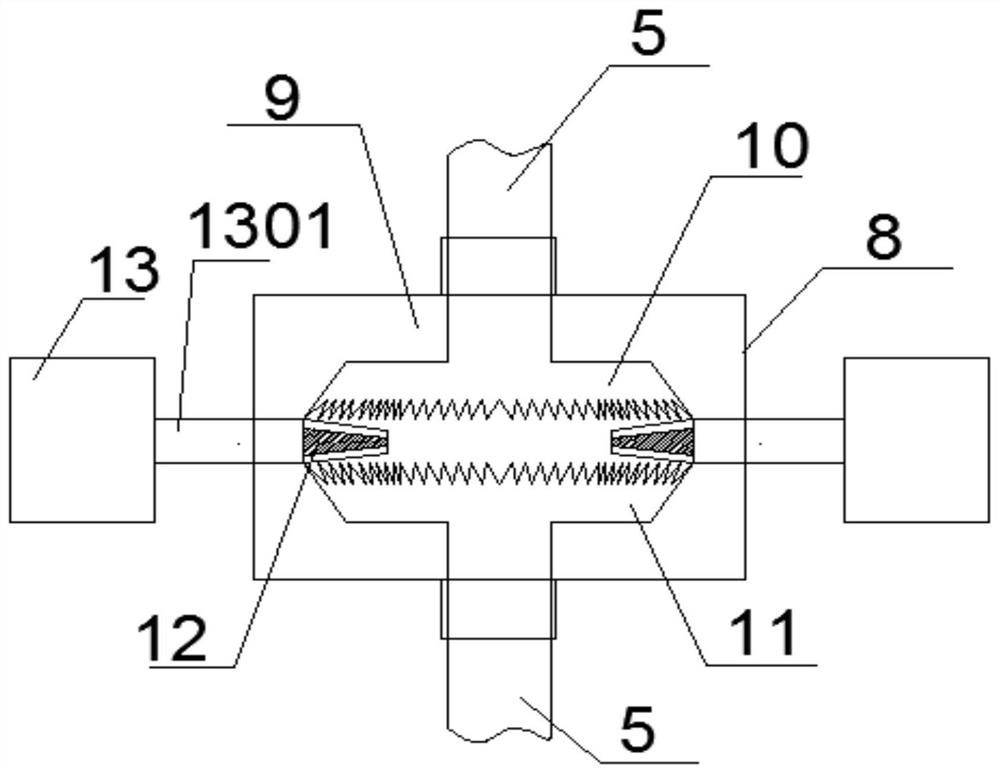

[0049] Specifically, such as figure 1 , as shown in 2, the power generation device of the present invention mainly includes a base 1, an annular support 2 and multiple sets of generating sets 3, the base 1 and multiple sets of generating sets 3 are arranged in the annular support 2, and the bottommost generating set 3. The base 1 is connected to the base 1 through the bearing 16. The base 1 is used to stabilize the stability of each generating set 3. Multiple sets of the generating sets 3 are sequentially connected in series through the transmission box 4 from bottom to top, so that the overall footprint is small and the power generation efficiency is high. The generating set 3 includes a plurality of support arms 6, impeller shafts 5 and blades 7 fixed on the support arms 6, one end of the plurality of support arms 6 is fixedly connected to the impeller shaft 5, and is radially distributed in the circumferential direction of the impeller shaft 5 , each support arm 6 is provid...

Embodiment 2

[0051] Specifically, such as Figure 9 As shown, a bracket 22 is welded or bolted between any adjacent two support arms 6, the bracket 22 can be set in an arc shape, and a plurality of auxiliary generators 20 are evenly distributed in a fan shape on the bracket 22, and the auxiliary generators 20 are fixed by bolts On the support 22, the rotor of the auxiliary generator 20 is radially along the annular support 2 and towards the annular support 2, which further increases the weight of the whole device and makes the stability and wind resistance of the device better, such as Figure 4-7 , shown in 10 and 11, the top surface of the annular support 2 is provided with an annular groove track 19, and the circular block 21 at the end of the guide wheel 14 and the rotor is located in the groove track 19, so that in the sliding process, the guide wheel 14 and the Circular block 21 is not easy to drop from ring support 2, is smeared with polytetrafluoroethylene on groove track 19 surfac...

Embodiment 3

[0053] Specifically, such as figure 1 As shown, the total number of layers of the generator set 3 is at least two layers. Since the rotation direction of any two adjacent layers of the generator set 3 is opposite, the wind blowing in from any direction can be collected, further improving the power generation of the generator set 3. Adaptability under various working conditions, and at the same time improve the collection and conversion efficiency of wind energy to electric energy, achieve the purpose of maximizing the use of wind energy to increase production capacity, and realize the increase of power generation current. The direction is opposite, so that the rotation directions of the adjacent two-layer generator sets 3 are opposite, which can offset the centrifugal force generated by the mutual rotation of the two-layer generator sets 3 on the impeller shaft 5, thereby protecting the impeller shaft 5 from damage and prolonging the service life of the power generation device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com