A method and device system for producing 1,2-hexanediol

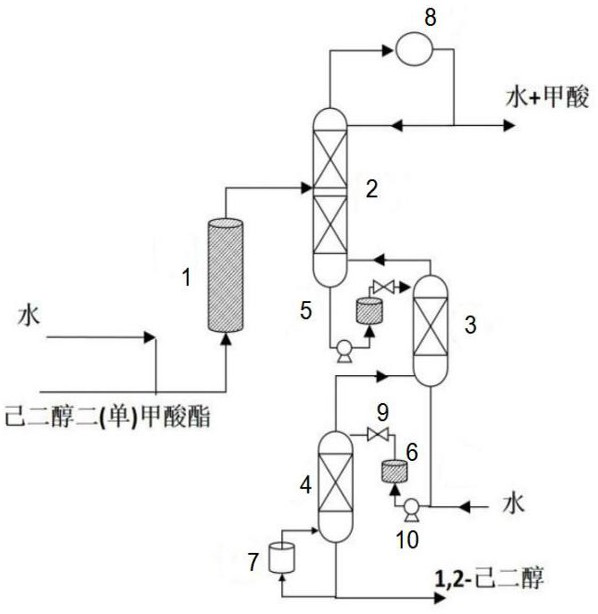

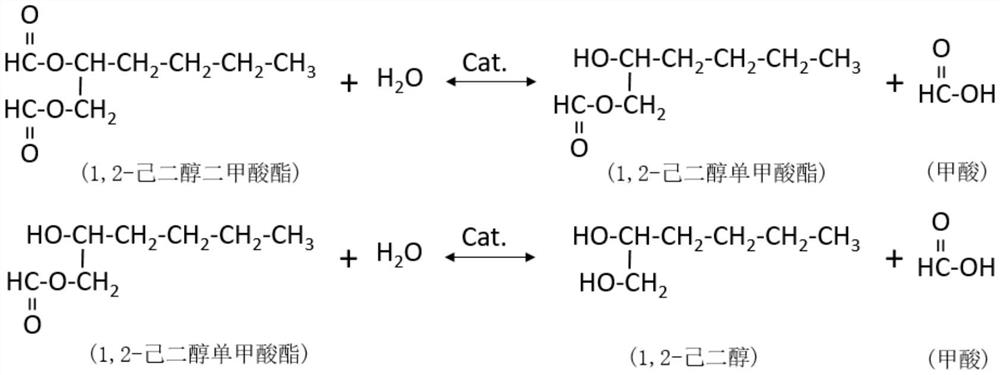

A technology of hexanediol, -II is applied in the field of hydrolysis reaction to prepare 1,2-hexanediol, which can solve the problems of low product yield and the like, and achieve the effects of simple process technology, improving conversion rate, and breaking the limit of hydrolysis balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The feed flow rate of 1,2-hexanediol dicarboxylate and water mixed liquid is 1000kg / h, and the feed molar composition: 1.2-hexanediol dicarboxylate:water=1:2. Send the mixed solution into the pre-reactor for pre-reaction, the residence time is 120min, and the pre-reaction temperature is 95°C. The theoretical board numbers of tower section-I, tower section-II and tower section-III are 20, 10 and 10 respectively. The residence time of reactor I and reactor II is 45min, and the temperature of the reactor is controlled to be 110°C. Tower section-I has a top pressure of 15kpa and a reflux ratio of 4. 145kg / h of supplementary water is fed to the bottom of the reactor II, 594.5kg / h of water and formic acid are produced at the top of the tower, and 564.3kg / h of crude 1,2-hexanediol is produced at the bottom of the tower. According to the material balance calculation, the single-pass hydrolysis rate of 1,2-hexanediol dicarboxylate is 99.1%. The crude product can obtain 99.5% ...

Embodiment 2

[0051] The feed flow rate of 1,2-hexanediol dicarboxylate and water mixture is 1000kg / h, 25°C, and the feed molar composition: 1.2-hexanediol dicarboxylate:water=1:4. Send the mixed liquid into the pre-reactor for pre-reaction, the pre-reaction temperature is 95°C, and the residence time is 60min. The number of theoretical boards of Tower Section-I, Tower Section-II and Tower Section-III are 24, 10 and 10 respectively. The residence time of reactor I and reactor II is 60min, and the temperature of the controlled reactor is 100°C. Tower section-I has a top pressure of 20kpa and a reflux ratio of 2. 148kg / h of supplementary water is fed to the bottom of the reactor II, 650.9kg / h of water and formic acid are produced at the top of the tower, and 481.3kg / h of crude 1,2-hexanediol is produced at the bottom of the tower. According to the material balance calculation, the single-pass hydrolysis rate of 1,2-hexanediol dicarboxylate is 99.3%. The crude product can obtain 469kg / h of ...

Embodiment 3

[0053] The feed flow rate of 1,2-hexanediol monoformate and water mixed liquid is 1000kg / h, 25°C, and the feed molar composition: 1.2-hexanediol monoformate: water = 1:2. Send the mixed liquid into the pre-reactor for pre-reaction, the pre-reaction temperature is 95°C, and the residence time is 100min. The number of theoretical boards of Tower Section-I, Tower Section-II and Tower Section-III are 24, 10 and 10 respectively. The residence time of reactor I and reactor II is 50min, and the temperature of the controlled reactor is 105°C. Tower Section-I has a top pressure of 15kpa and a reflux ratio of 3. 198kg / h of supplementary water is fed to the bottom of the reactor II, 540.6kg / h of water and formic acid are produced at the top of the tower, and 649.7kg / h of crude 1,2-hexanediol is produced at the bottom of the tower. According to the material balance calculation, the single-pass hydrolysis rate of 1,2-hexanediol dicarboxylate is 99.1%. The crude product can obtain 99.5% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com