Controllable preparation method of modified hydroxyapatite powder based on microfluidic control and hydroxyapatite nano particles

A hydroxyapatite and nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as reducing skin feel effect, poor dispersibility, etc., and achieve rich sources and particle size. Small, highly biocompatible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of Nanometer Hydroxyapatite Nuclei

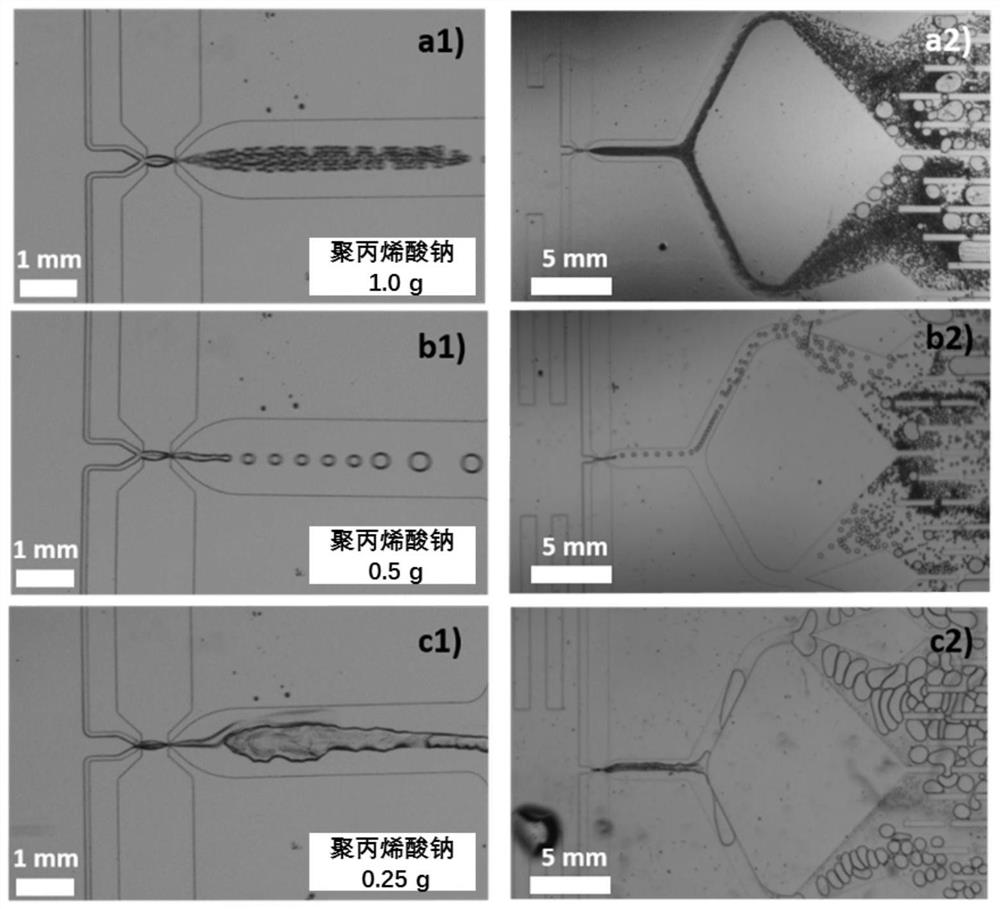

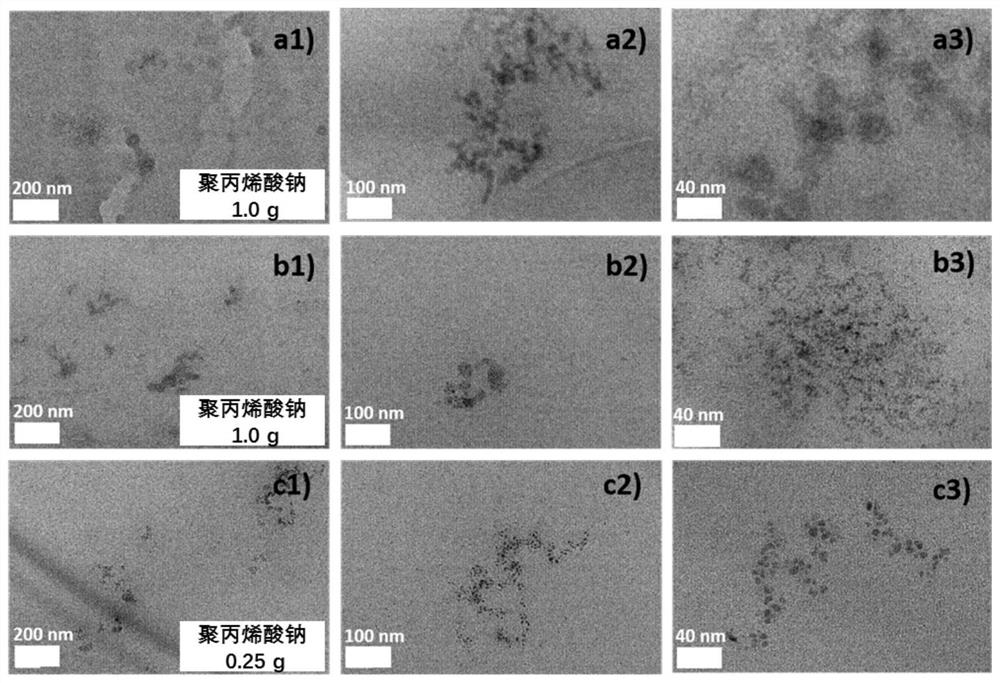

[0041] First prepare CaCl with a concentration of 0.01M 2 aqueous solution, adding a sodium polyacrylate aqueous solution with a molecular weight of 30,000 Da, and stirring and mixing the two for 6 hours. At the same time, the preparation concentration of 0.006M (NH 4 ) 2 HPO 4 aqueous solution, and adjust the pH to 10 with ammonia water. Three groups of parallel experiments were done, and the added sodium polyacrylate aqueous solution was 0-4 mg / mL.

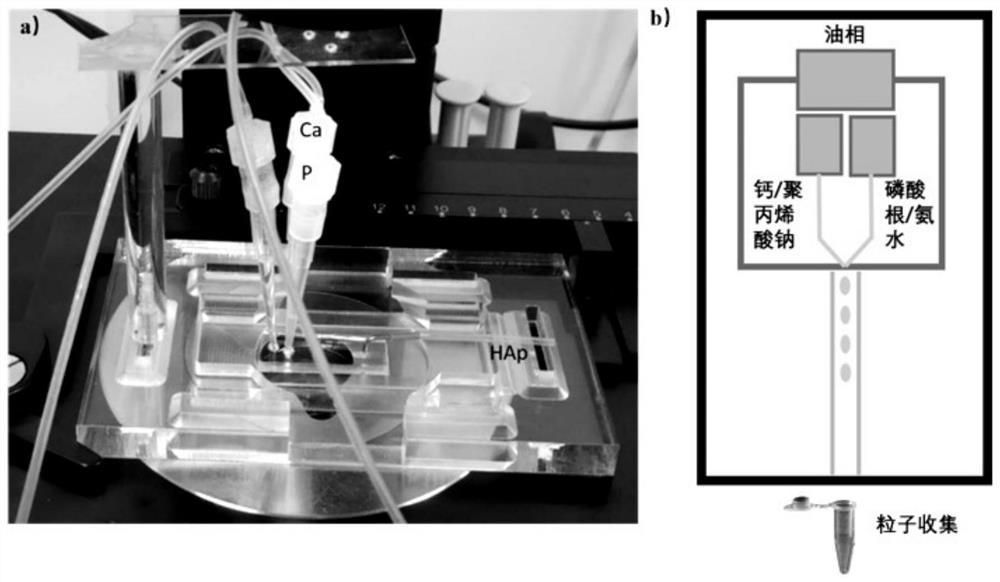

[0042] refer to figure 1 As shown, the oil phase solution is configured as the continuous phase of the microfluidic system, and the oil phase is composed of mineral oil, oleic acid and Span-80, and the ratio is 98:1:1. Place phase A and phase B of the calcium and phosphorus precursor solution in the two water phase channels of the microfluidic system, place C phase mineral oil in the oil phase channel, and simultaneously use air pressure to squeeze the two phases A an...

Embodiment 2

[0052] Preparation of Nanometer Hydroxyapatite Nuclei

[0053] First prepare CaCl at a concentration of 0.01M to 0.04M 2 aqueous solution, adding a sodium polyacrylate aqueous solution with a molecular weight of 30,000 Da and a final concentration of 4 mg / mL, and stirring and mixing the two for 6 hours. At the same time, the preparation concentration of 0.006M (NH 4 ) 2 HPO 4 aqueous solution, and adjust the pH to 10 with ammonia water. The oil phase solution was configured as the continuous phase of the microfluidic system, and the oil phase was composed of mineral oil, oleic acid and Span-80 at a ratio of 98:1:1. Place A and B phases of calcium and phosphorus precursors in the two water phase channels of the microfluidic system, and place C phase mineral oil in the oil phase channel. At the same time, the two phases A and B are extruded into the reaction system by air pressure, and the primary crystal nucleus of calcium phosphate is formed at the intersection of the two...

Embodiment 3

[0056] Preparation of nano-hydroxyapatite

[0057] First prepare CaCl with a concentration of 0.01M 2 aqueous solution, adding a sodium polyacrylate aqueous solution with a molecular weight of 30,000 Da and a final concentration of 4 mg / mL, and stirring and mixing the two for 6 h. At the same time, the preparation concentration of 0.006M (NH 4 ) 2 HPO 4 aqueous solution, and adjust the pH to 10 with ammonia water. Aqueous solution of sodium polyacrylate was added.

[0058] The oil phase solution was configured as the continuous phase of the microfluidic system, and the oil phase was composed of mineral oil, oleic acid and Span-80 at a ratio of 98:1:1. Place A and B phases of calcium and phosphorus precursors in the two water phase channels of the microfluidic system, and place C phase mineral oil in the oil phase channel. At the same time, the two phases A and B are extruded into the reaction system by air pressure, and the primary crystal nucleus of calcium phosphate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com