Pipeline placing device for building engineering

A construction engineering and pipeline technology, applied in the field of pipeline placement devices for construction engineering, can solve problems such as damage to workers and collapse, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

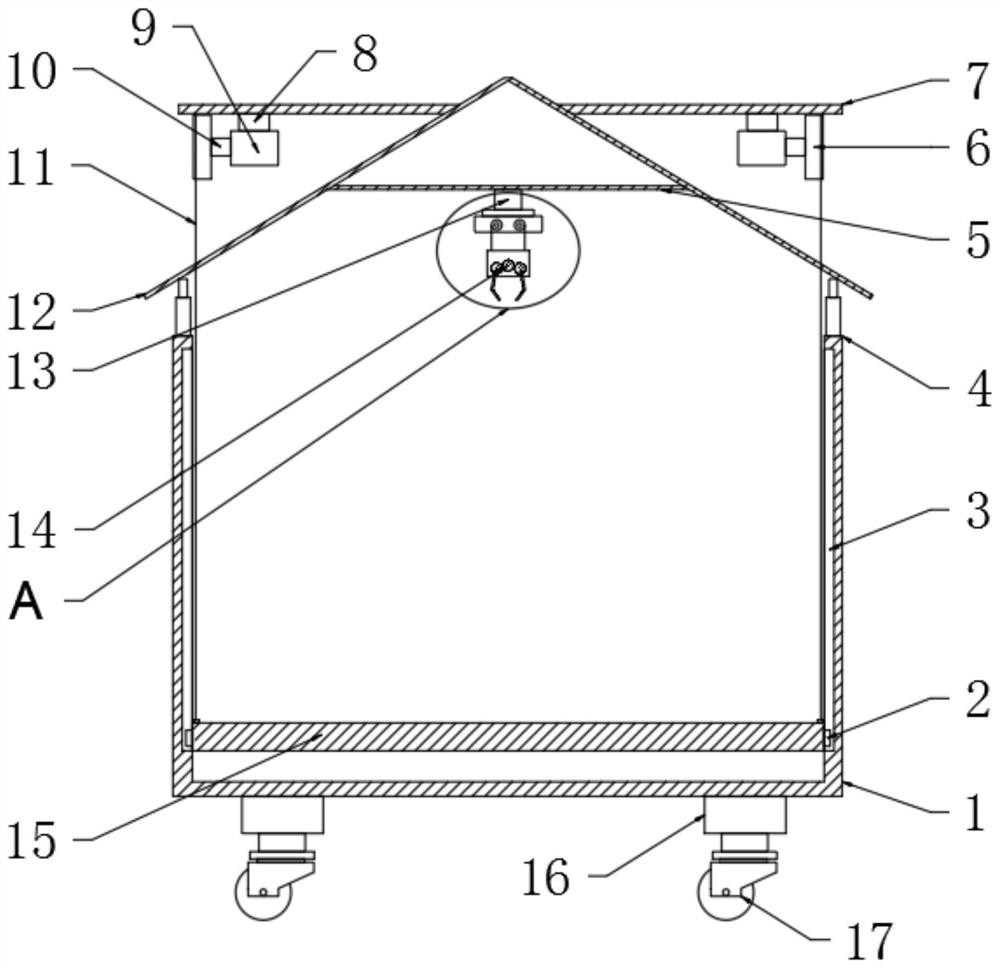

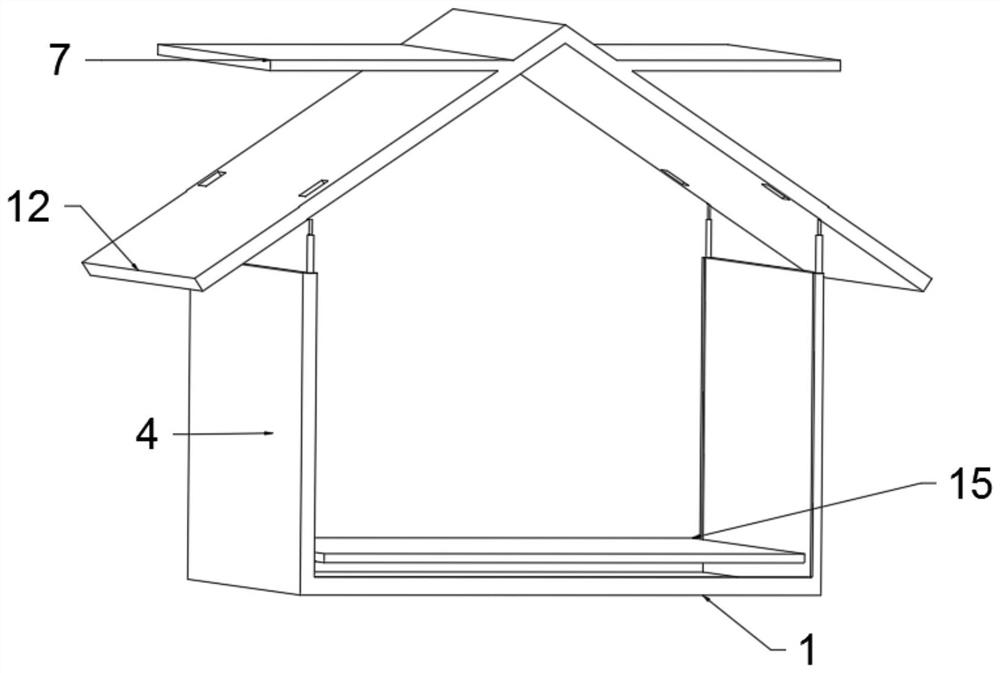

[0020] see Figure 1-4 , a pipeline placement device for construction engineering, comprising a base 1, a placement plate 15 and a pipeline removal structure, a placement plate 15 is arranged above the base 1, a pipeline removal structure is arranged above the placement plate 15, and the pipeline The unloading structure includes a single pipe unloading mechanism and an integral unloading mechanism, a side support bar 4 is arranged on the upper side of the base 1, and a top slant plate 12 is provided at the end of the side support bar 4, and the top slant A horizontal plate 1 is arranged inside the middle of the plate 12, a horizontal plate 2 7 is arranged on the outside of the top slant plate, a single pipe removal mechanism is arranged under the horizontal plate 1 5, and a horizontal plate 2 7 is arranged below the sides An integral removal mechanism, the end of the overall removal mechanism is provided with a traction rope 11, the side of the placement plate 15 is provided w...

Embodiment 2

[0027] Compared with Embodiment 1, the improvement of this embodiment lies in that: a telescopic rod 16 is provided under the base 1 , and a universal wheel 17 is provided at the end of the telescopic rod 16 . In the transportation process, universal wheels 17 can be used to move and transport the whole box body, which is convenient and fast.

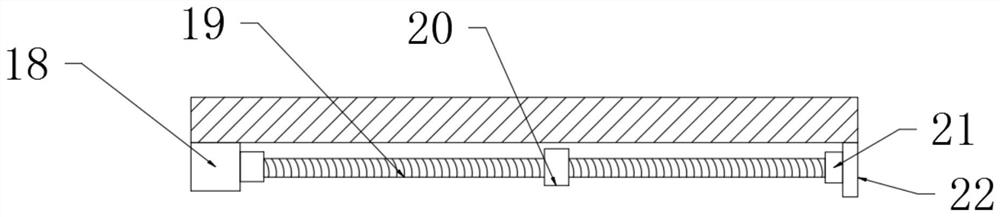

[0028] The working principle of the present invention is: place the pipeline on the placement plate 15, and when it needs to be extracted for utilization, a single pipeline is needed, and the horizontal motor 18 is used to drive the horizontal ball screw 19, so that the fixed sleeve 20 moves laterally, so that the clamping structure 14 Arrive at a suitable position, then according to the rotation of gear one 30, drive the rotation of gear two 29 and gear three 25, so that the clamping block 27 expands, and the pipe is approached, and then the gear two 29 and gear three 25 are reversely rotated to clamp At the same time, the suction cup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com