Automatic loading and once-bending equipment for binding post semi-finished product

An automatic feeding and terminal technology, which is used in metal processing equipment, forming tools, contact manufacturing, etc., can solve the problems of complex terminal forming process and lack of terminal posts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

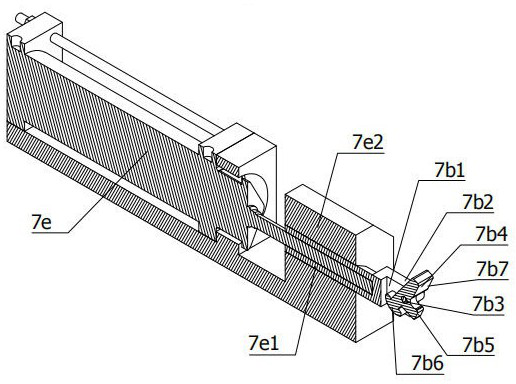

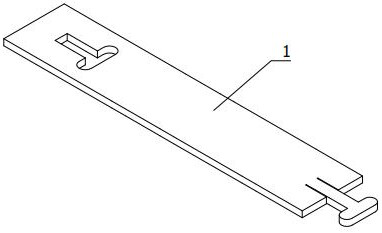

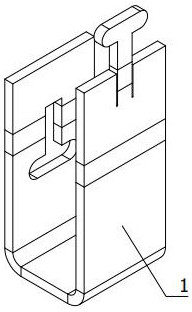

[0045] An automatic bending production line for terminal semi-finished products, which is applied to bending processing terminal 1, so that terminal 1 can be figure 1 The first forming state shown is sequentially bent into figure 2 , image 3 The second and third molding states are shown, such as Figure 4 , 5 As shown, it includes a workbench, a material collection mechanism 8, a controller, and a sequentially arranged feeding mechanism 2, a first material transfer mechanism 3, a first bending mechanism 4, a second material transfer mechanism 5, and a third material transfer mechanism. Mechanism 6, the second bending mechanism 7, the material collecting mechanism 8 is arranged on the side of the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com