Large workpiece riveting device

A technology for large workpieces and rivets, applied in the field of large workpiece rivets, can solve problems such as difficulty in grasping strength, physical harm to workers, and difficulty in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

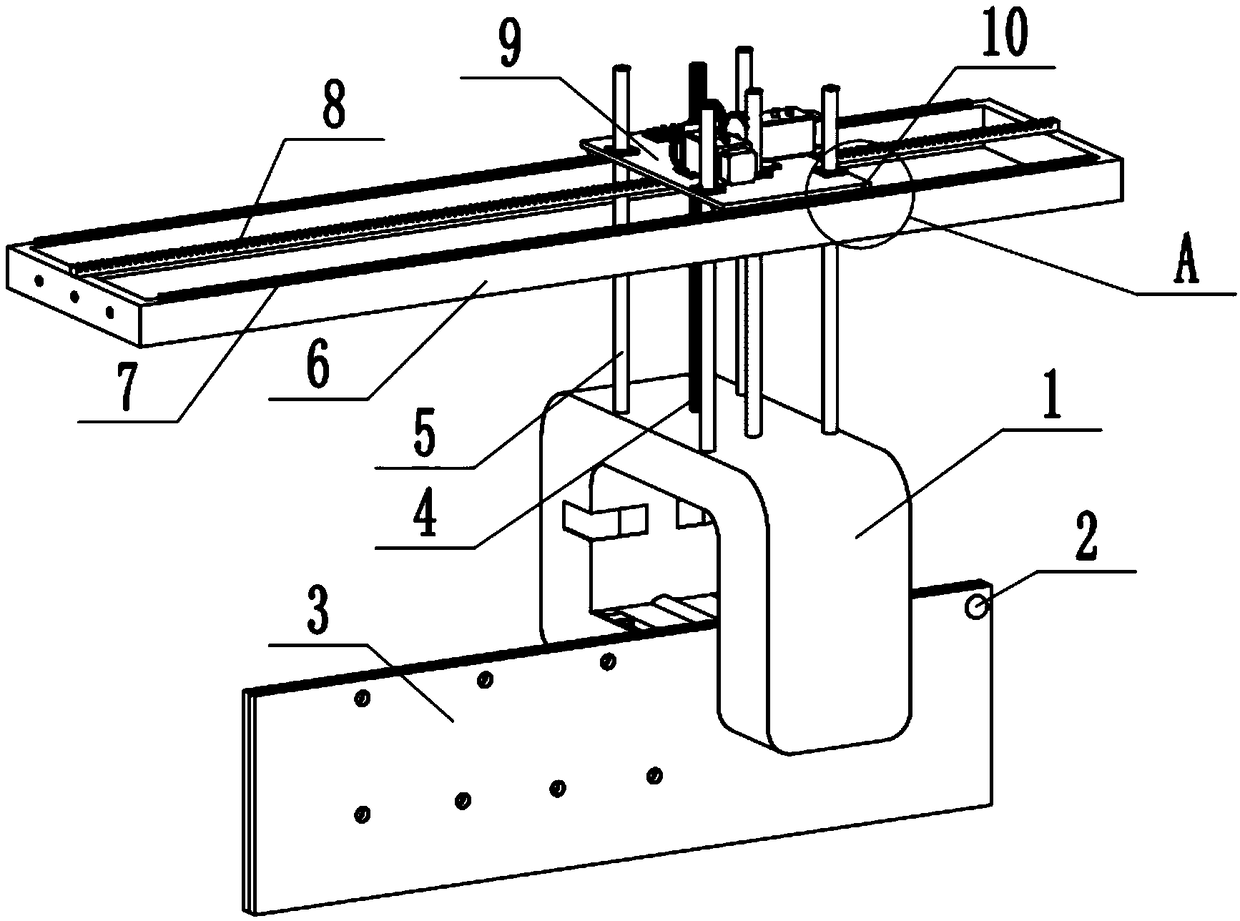

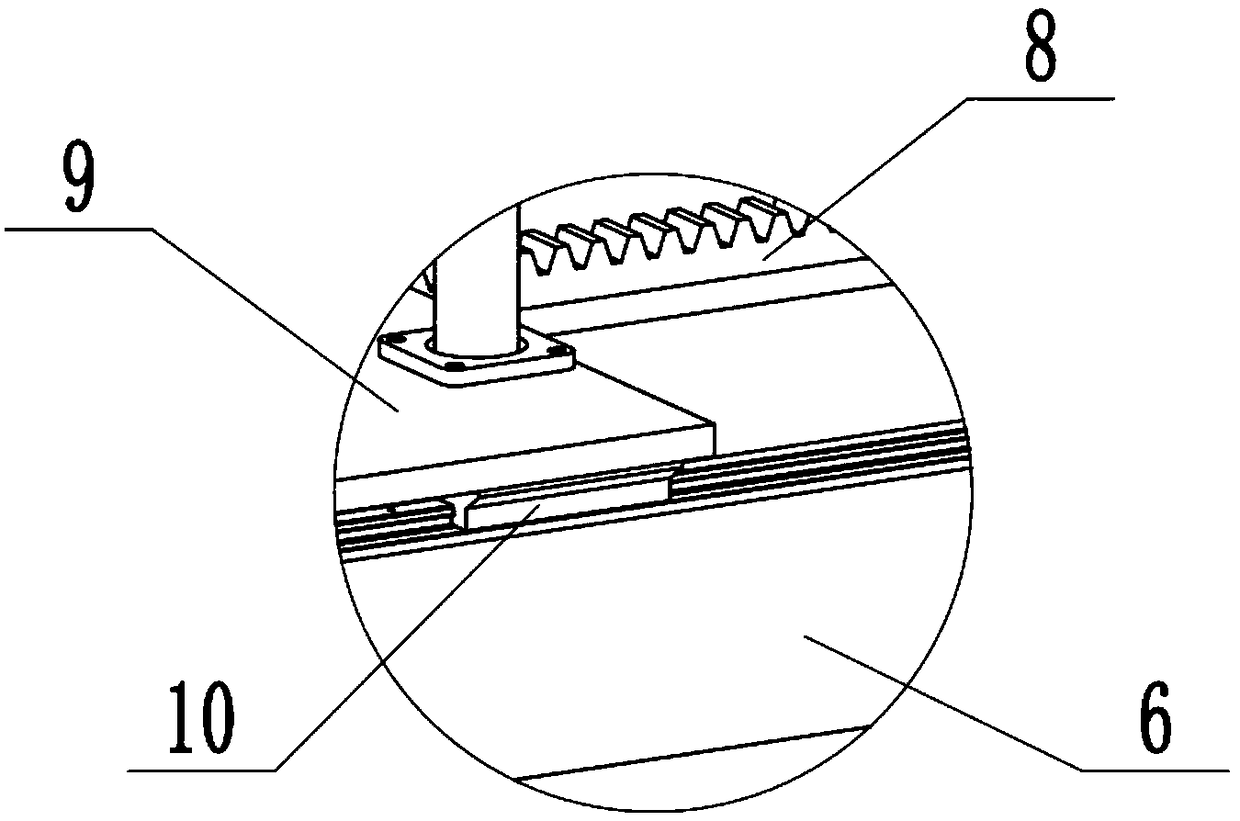

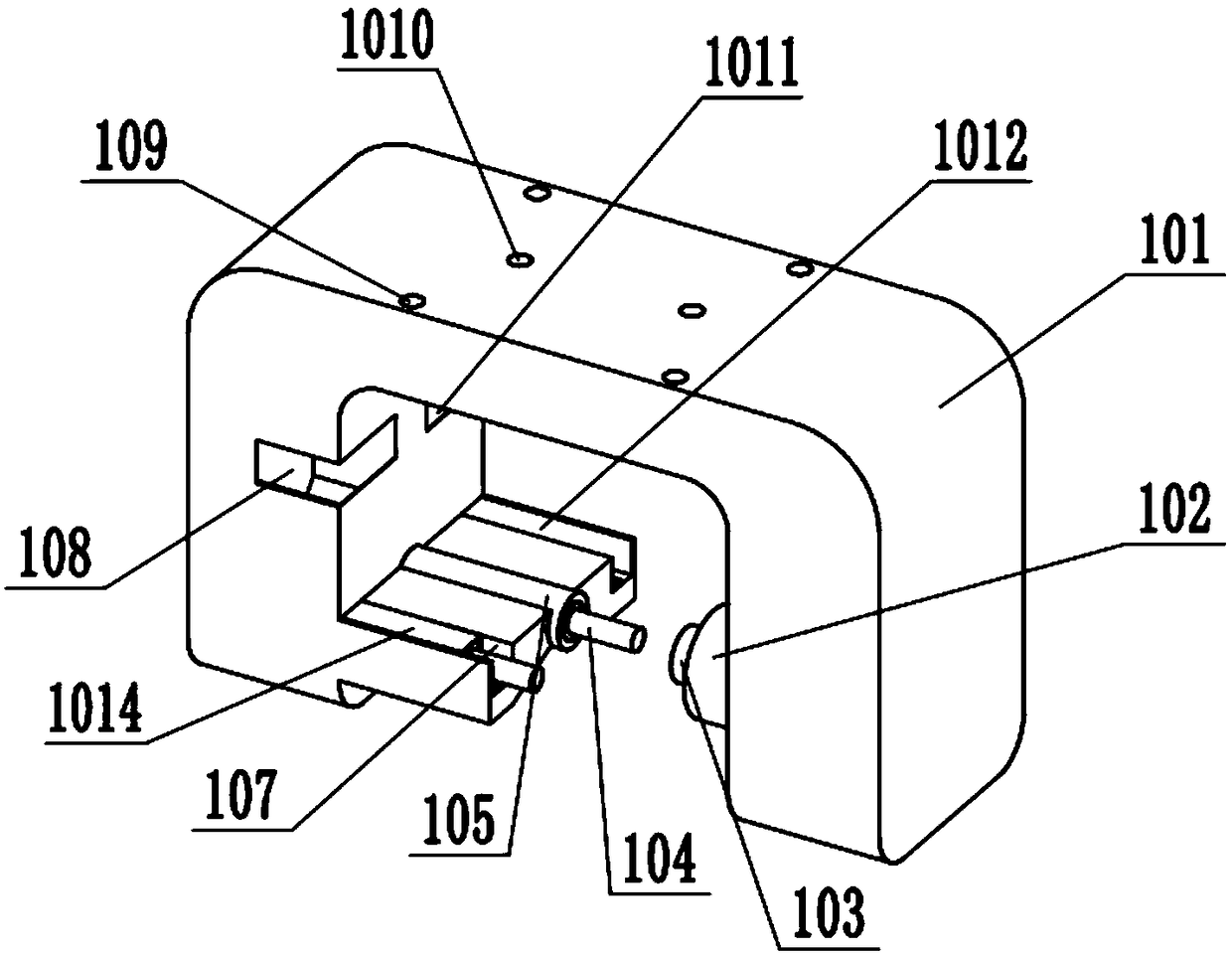

[0029] A method for riveting large workpieces, the method is to use the joint action of the upper assembly 9 and the lower assembly 1 to realize the free movement of the device in the horizontal and vertical directions, and realize the joint action of the first hydraulic cylinder 103 and the second hydraulic cylinder 105 The compression and intensification of the rivet 104 work, the device is composed of the lower assembly 1, the rivet 104 completed part 2, the large processing plate 3, the cylindrical rack 4, the optical axis 5, the support frame 6, the slide rail 7, the rack 8, the upper The component 9 and the slider 10 are composed of two large-scale processing boards 3, and the two large-scale processing boards 3 are aligned and placed, and the openings on the large-scale processing board 3 are aligned in pairs; the orange finished parts are installed on the Two large processing boards 3 are tightened at the opening of the large processing board 3; the large processing boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com