Method for in-situ preparation of TEM sample of nanoscale particles in sample with complex structure

A complex structure, in-situ preparation technology, applied in the fields of planetary science and planetary exploration, can solve the problems of wasting sample resources, unavoidable sample contamination, inability to perform polishing, etc., to reduce pollution, simplify operation procedures, and overcome area damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

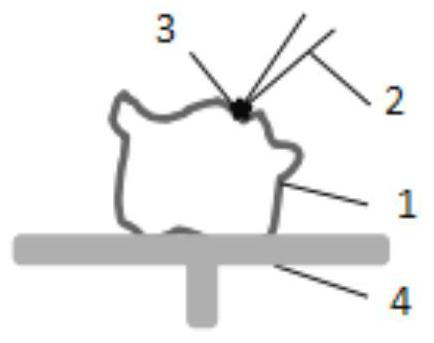

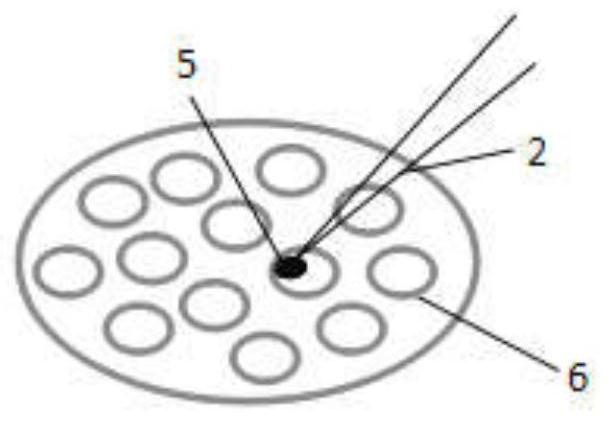

[0036] In this example, a TEM sample of nanoscale particles in samples with a complex structure was prepared in situ using a double beam electron microscope, and a schematic diagram of extracting nanoscale particles on the sample surface and fixing nanoscale particles on a copper grid by using a double beam electron microscope is as follows Figure 1~2 As shown, the specific steps are as follows:

[0037] (1) The sample used in this example is a dolomite block sample, which has irregular shape, uneven appearance, complex surface phase structure, and differences in composition and morphology of different parts of the surface, so the surface of the sample cannot be pre-polished. And there are nanoscale particles on the sample, and these nanoscale particles are aggregated together to form nanoparticle clusters.

[0038] Fix the sample on the sample holder with carbon conductive tape and copper conductive tape, such as image 3 As shown, the sample holder is then placed on the sa...

Embodiment 2

[0043] In this example, a TEM sample of nanoscale particles in a sample with a complex structure was prepared in situ using a double-beam electron microscope, and the steps were as follows:

[0044] (1) The sample used in this example is a simulated lunar soil sample. In order to ensure in-situ extraction, the sample is not suitable for dispersion treatment with alcohol, and there are nano-scale particles on the sample, and these nano-scale particles gather together to form nano-particle clusters cluster.

[0045] Fix the sample on the sample holder with carbon conductive tape, then place the sample holder on the sample stage in the sample chamber of the double-beam electron microscope, install the copper mesh in the slot horizontal to the sample stage, and make the copper mesh and the sample stage On the same level, seal the sample chamber and evacuate the sample chamber. After the vacuum degree of the sample chamber meets the requirements, use the scanning electron microscop...

Embodiment 3

[0050] In this example, a TEM sample of nanoscale particles in a sample with a complex structure was prepared in situ using a double-beam electron microscope, and the steps were as follows:

[0051] (1) The sample micron SiO used in this embodiment 2 A powder sample that has nanoscale particles on its surface that aggregate together to form nanoparticle clusters.

[0052] Fix the sample on the sample holder, then place the sample holder on the sample stage in the sample cavity of the double-beam electron microscope, install the copper mesh in the slot horizontal to the sample stage, so that the copper mesh and the sample stage are on the same level , seal the sample cavity and evacuate the sample cavity. After the vacuum degree of the sample cavity meets the requirements, use the scanning electron microscope function of the double-beam electron microscope to observe the surface morphology of the sample and find the nanoparticle cluster area of interest, such as Image 6 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com