A new type of odorless paint room

A paint booth, a new type of technology, applied in the spray booth, separation method, dispersed particle separation and other directions, can solve the problems of large equipment, clean the paint smell of the paint environment, no paint space, etc., to ensure full utilization, smooth air circulation, paint Breathless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

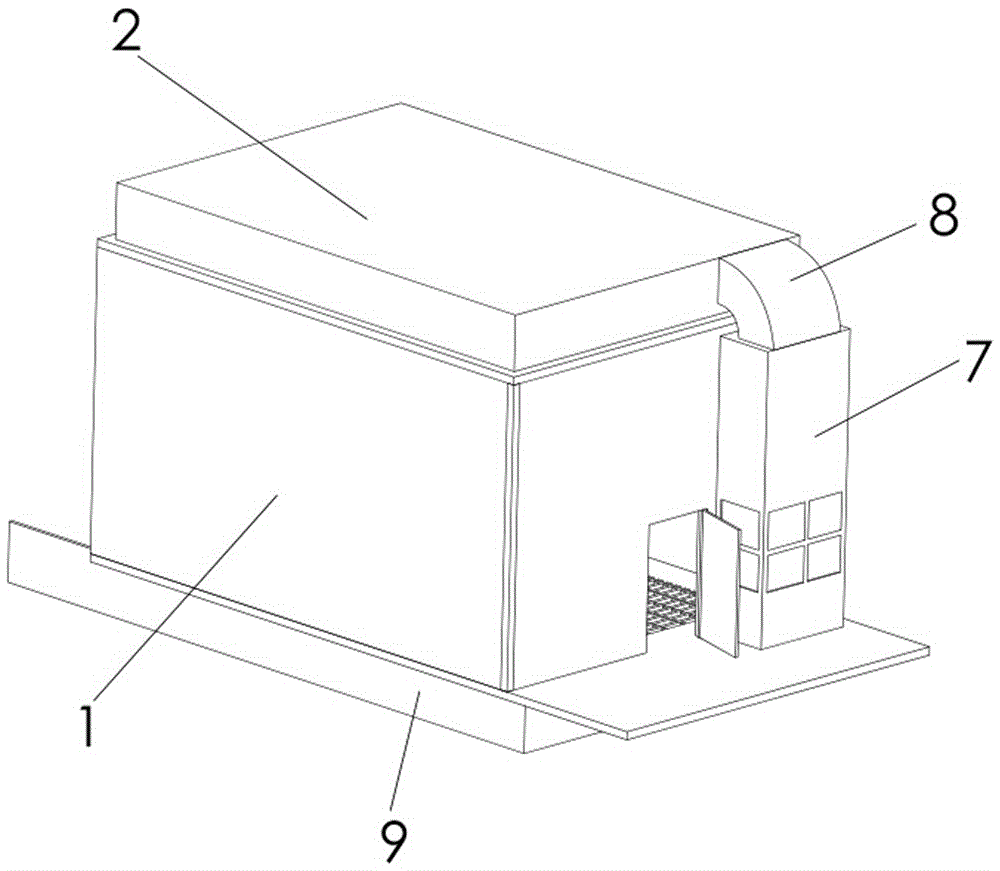

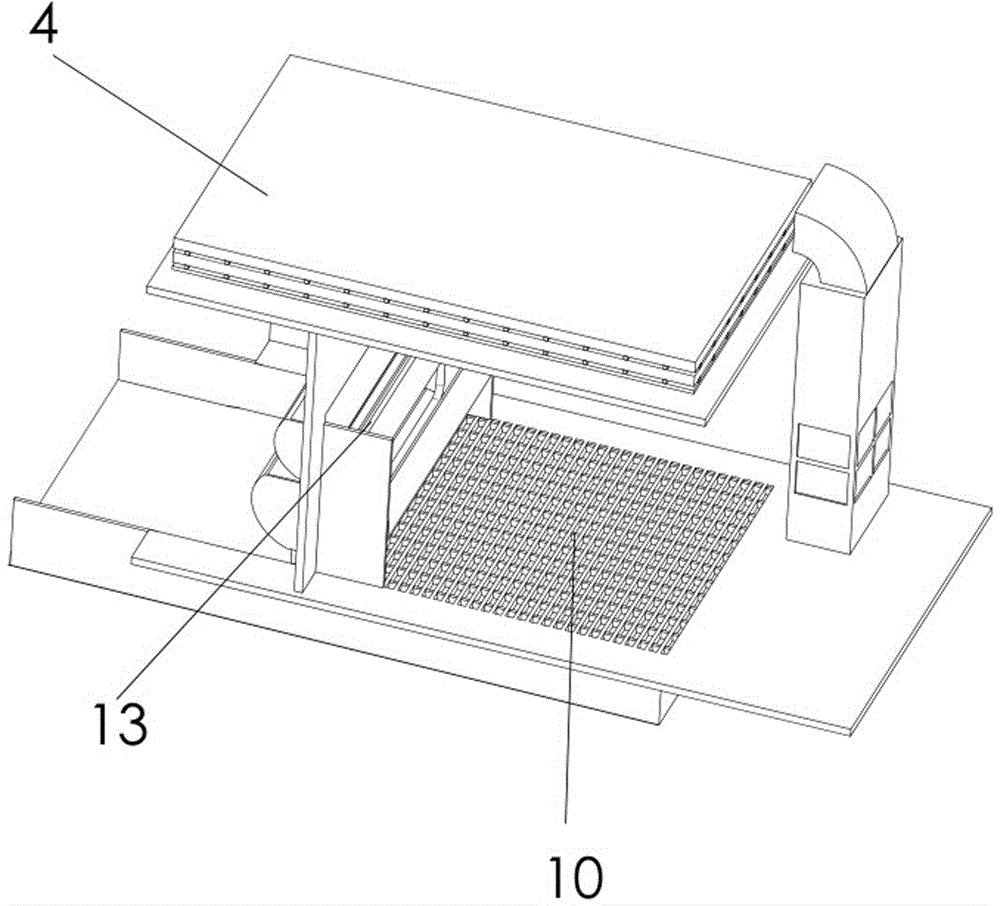

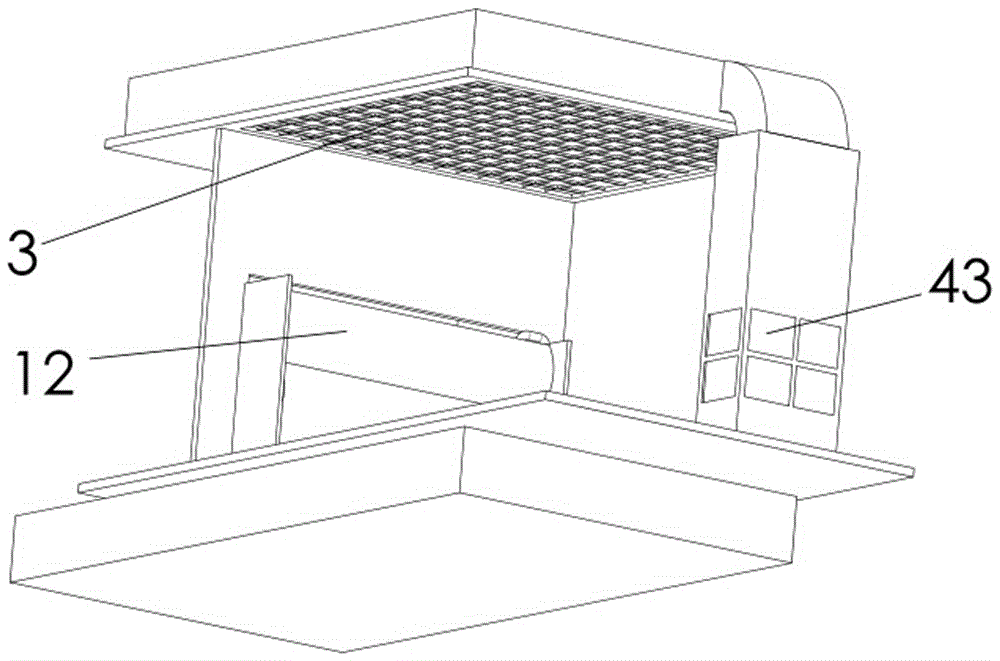

[0036] A new type of odorless paint room, including a room body enclosed by walls 1 and roof 2, an indoor floor located in the room, and an air supply device installed outside the room for supplying air from top to bottom in the room 1. A deodorizing and sewage device installed in the room for absorbing and discharging the paint smell, a top net frame 3 erected on the wall is arranged under the roof, and a top net frame for filtering and absorbing dust is laid on the top net frame Filter cotton 4, air supply cavity is formed between described filter cotton and the roof, and described air supply device comprises the exhaust air box 7 that is arranged on the outside of the room, is arranged on the exhaust port 71 on the exhaust air box and is used for the exhaust air of the exhaust air box. The wind drawn in by the machine is sent to the air supply pipe 8 of the air supply chamber, and a grid frame is set up on the air suction port, and a yarn layer 43 for filtering air is provid...

Embodiment 2

[0044] The difference from the above embodiment is that there are multiple layers of filter cotton on the top grid frame, and there are net pressing plates between the upper and lower filter cotton and on the top filter cotton, and the net pressing plates are metal mesh frame plates.

Embodiment 3

[0046] The difference from the above embodiment is that two long water tanks are arranged up and down on the shelf plate.

[0047] The invention uses the filtered natural wind blowing down from the roof to blow the sprayed and floating paint and the air with paint smell down to the drainage pool, where it is absorbed by the water and discharged from the paint room through the sewage outlet. The air is also circulated through the blowdown outlet. The air will also be mixed with some paint and paint smell. A water tank is also installed at the sewage outlet. The water in the water tank is full to form a water curtain to filter the air passing through the sewage outlet, so as to remove the air discharged from the paint room to the sewage outlet. The paint and paint smell, so that the paint smell and paint in the paint room are absorbed by the circulating water, and the circulating water is discharged from the sewage outlet for purification and recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com