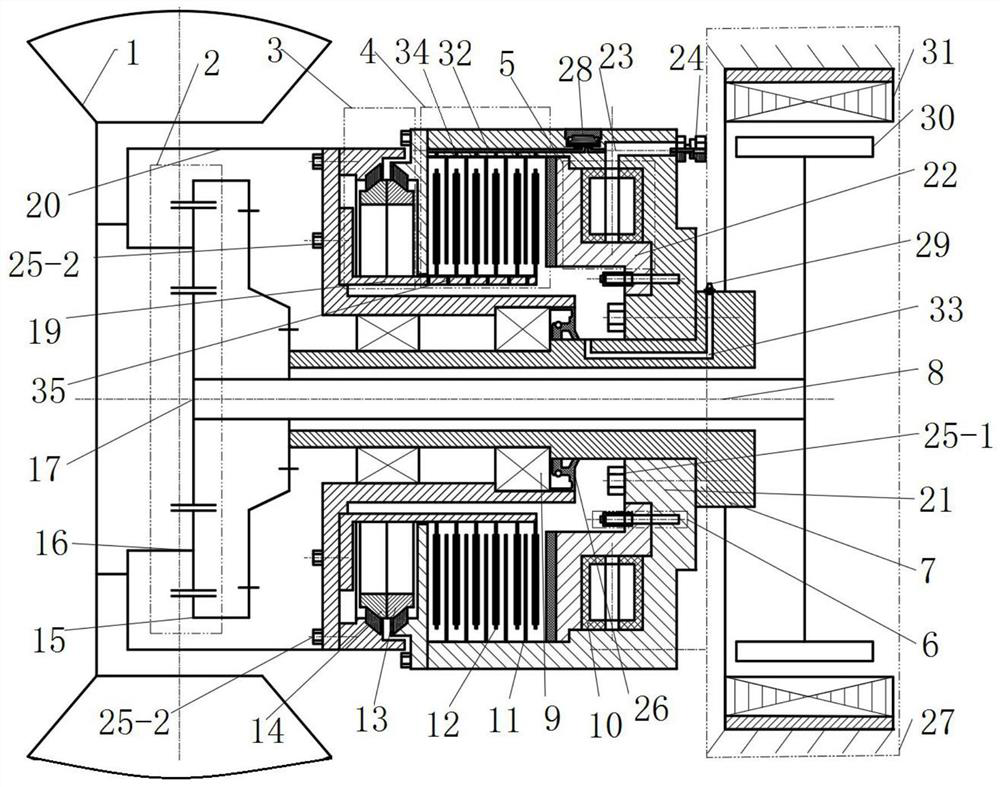

A heavy-duty electric vehicle wheel power and braking system assembly

A technology for electric vehicles and braking systems, which is applied in the direction of brake types, brake components, axial brakes, etc., which can solve the problems of large impact on brake performance, easy heat generation of brakes, and inconvenient vehicle design, so as to save installation space , good braking performance and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0087] This embodiment provides a braking method for the hub full-disc brake described in Embodiment 1, and the specific steps include:

[0088] When braking, at first the motor / generator integrated machine 27 is made to work in the generator mode, and the motor / generator integrated machine 27 produces a braking torque. The mechanical energy of the vehicle is converted into electrical energy and stored in the battery; after the vehicle speed is reduced, it is braked by the full disc brake.

[0089] When the brake is applied, the controlled high-pressure gas enters the cylinder of the pressurizing unit 5 through the cylinder valve 24 from the cylinder air channel 23 . The cylinder pushes the cylinder pressure plate 22 to move toward one side of the brake dynamic friction plate 12 . The cylinder pressure plate 22 drives the static friction plate 11 to contact with the dynamic friction plate 12 and squeeze each other to generate braking torque. The braking torque is transmitted...

Embodiment 3

[0095] This embodiment provides a heat dissipation method for the wheel power and braking system assembly of the heavy-duty electric vehicle in Embodiment 1, including the following steps:

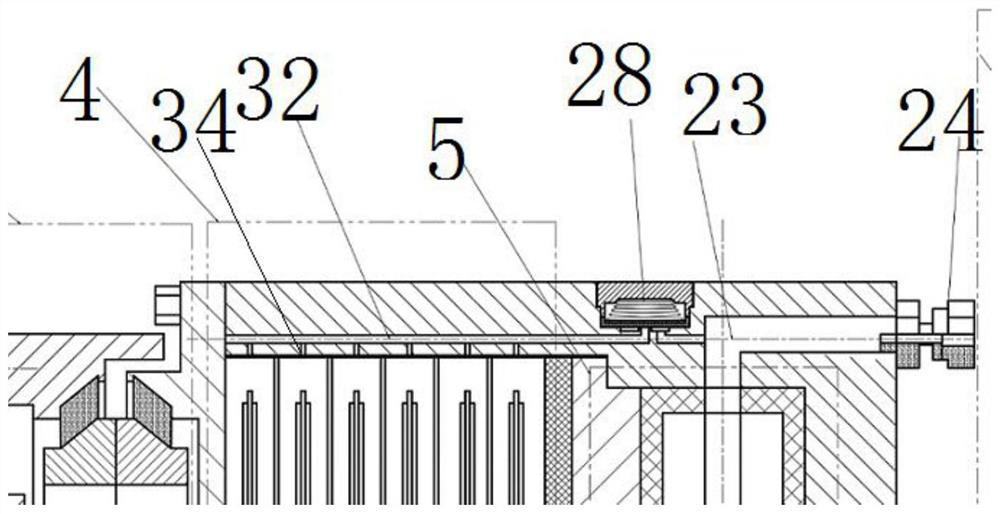

[0096] Step S1: delivering cooling gas to the interior of the brake assembly 4 through the cylinder air passage 23;

[0097] Step S2: When the air pressure in the air passage 23 of the cylinder reaches the opening pressure of the overflow valve 28, the air inlet passage 32 for cooling is communicated with the air passage 23 of the cylinder;

[0098] Step S3: The cooling air flows sequentially through the cylinder air passage 23, the overflow valve 28, the heat dissipation air inlet 32 and the air intake hole 34 and enters the interior of the brake assembly 4, and the high-temperature air flow inside the brake assembly 4 passes through the exhaust hole 35 and the heat dissipation The exhaust channel 33 flows out of the brake assembly 4 and takes away the heat generated by the friction bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com