Oil base mud and landing oil sand treatment device and technology

An oil-based mud and treatment device technology, which is applied to mixers with rotary stirring devices, transportation and packaging, chemical/physical processes, etc. The effect of reducing the extraction time, reducing the oil content of the mud and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

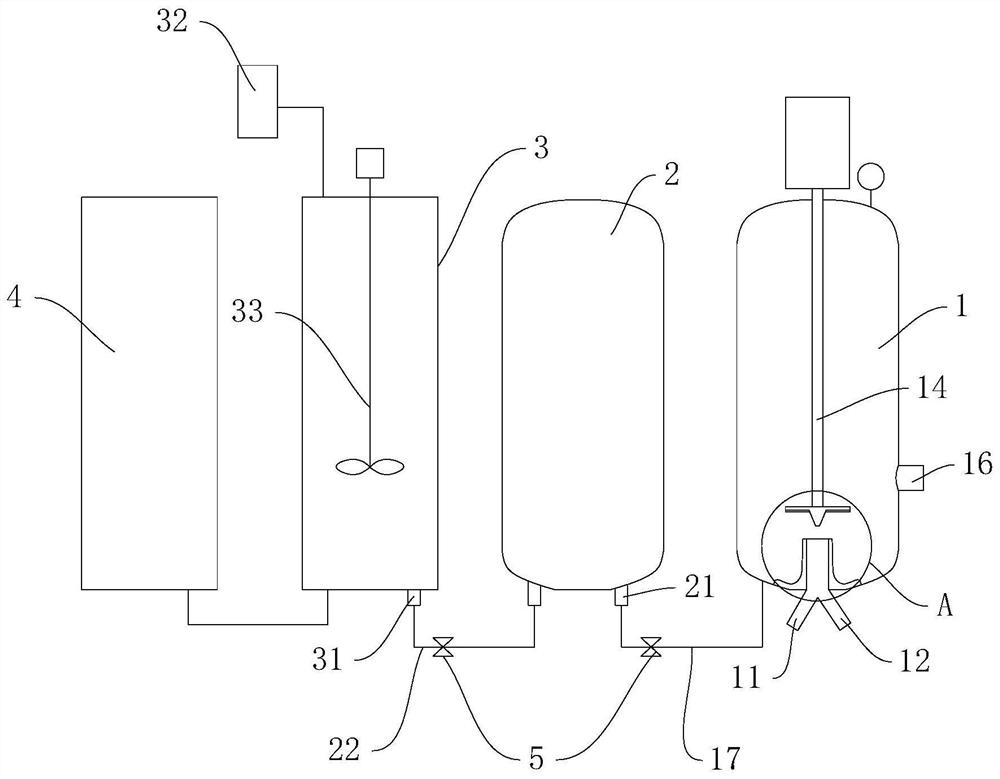

[0036] Embodiment 1, the oil-based mud treated in this embodiment has an oil content of about 30%, a treatment process for oil-based mud and ground oil sand, which is characterized in that it is carried out according to the following steps:

[0037] S1: Pass the oil-based mud and ground oil sand into the extraction tank through the mud feed port one;

[0038] S2: Adjust the temperature inside the extraction kettle 1 to 38°C, adjust the pressure inside the extraction kettle 1 to 8.5MPa, feed the extraction agent and co-extraction agent into the feed pipe 1 and feed pipe 2 respectively, 15ml of extractant per gram of mud , the ratio of extraction agent to co-extraction agent is 45:1, the extraction agent is CO2, and the co-extraction agent includes: 12 parts of ethanol, 10 parts of ethyl propionate; 6 parts of propiophenone;

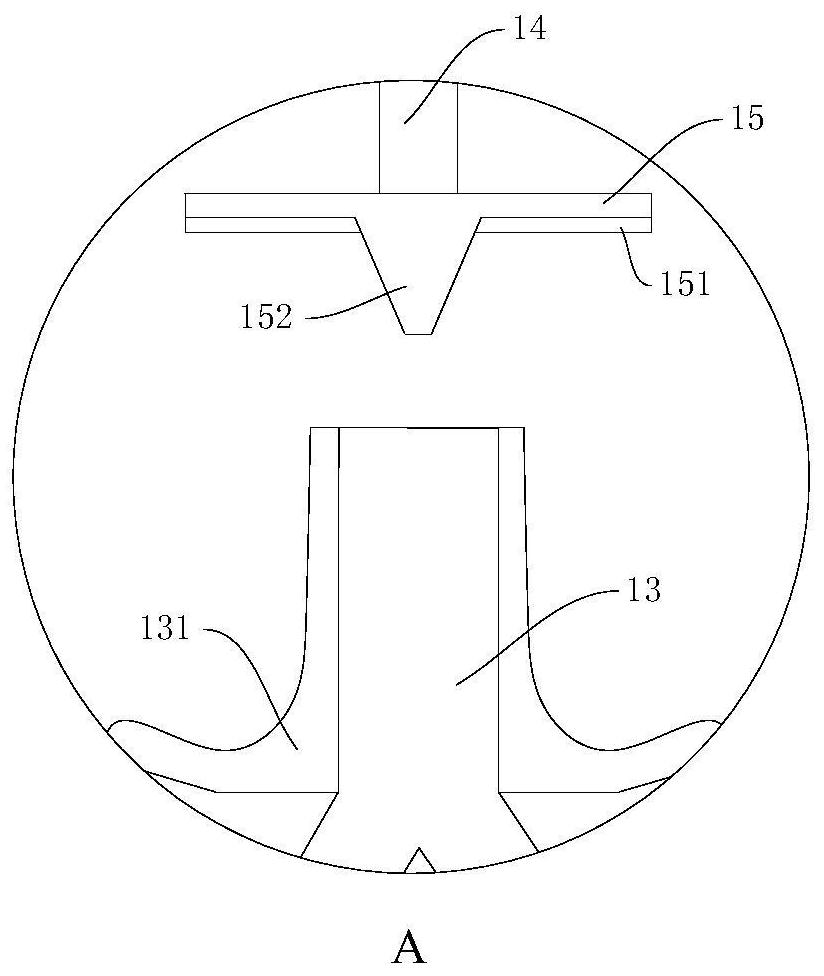

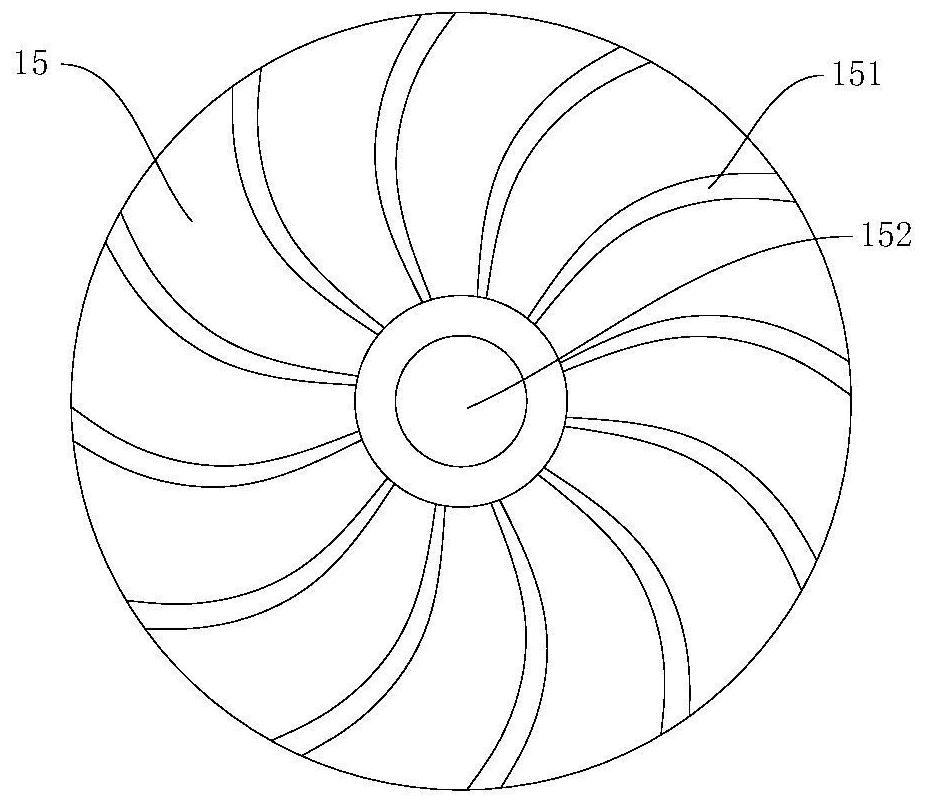

[0039] S3: While feeding the extraction agent and co-extraction agent, rotate the rotating rod at a speed of 20r / s, and the mixing plate mixes the mud wit...

Embodiment 2

[0043] Embodiment 2, the oil-based mud treated in this embodiment has an oil content of about 30%, a treatment process for oil-based mud and ground oil sand, which is characterized in that it is carried out according to the following steps:

[0044] S1: Pass the oil-based mud into the extraction tank through the mud feed port one;

[0045] S2: Adjust the temperature inside the extraction kettle 1 to 42°C, adjust the pressure inside the extraction kettle 1 to 9MPa, feed the extraction agent and the co-extraction agent into the feed pipe 1 and the feed pipe 2 respectively, 18ml of extractant per gram of mud, The ratio of extraction agent to co-extraction agent is 42:1, the extraction agent is CO2, and the co-extraction agent includes: 12 parts of ethanol, 10 parts of ethyl propionate; 6 parts of propiophenone;

[0046] S3: While feeding the extraction agent and co-extraction agent, rotate the rotating rod at a speed of 20r / s, and the mixing plate mixes the mud with the extractio...

Embodiment 3

[0050] Embodiment 3, the oil-based mud treated in this embodiment has an oil content of about 30%, a treatment process for oil-based mud and ground oil sand, which is characterized in that it is carried out according to the following steps:

[0051] S1: Pass the oil-based mud into the extraction tank through the mud feed port one;

[0052] S2: Adjust the temperature inside the extraction tank 1 to 47°C, adjust the pressure inside the extraction tank 1 to 9.5MPa, feed the extractant and co-extractant into the feed pipe 1 and feed pipe 2 respectively, 16ml of extractant per gram of mud , the ratio of extractant to co-extractant is 38:1, the extractant is CO2, and the co-extractant includes: 12 parts of ethanol, 10 parts of ethyl propionate; 6 parts of propiophenone;

[0053] S3: While feeding the extraction agent and co-extraction agent, rotate the rotating rod at a speed of 20r / s, and the mixing plate mixes the mud with the extraction agent and co-extraction agent. The extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com