Installation method for oblique crossing steel pipe and grid column type outer frame barrel body structure

A technology of oblique steel pipes and installation methods, which is applied in the direction of building construction, construction, and building materials processing, can solve the problems of long construction period, complicated installation method, low construction safety and reliability, and achieve short construction period and high construction efficiency. Simple method, high construction safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

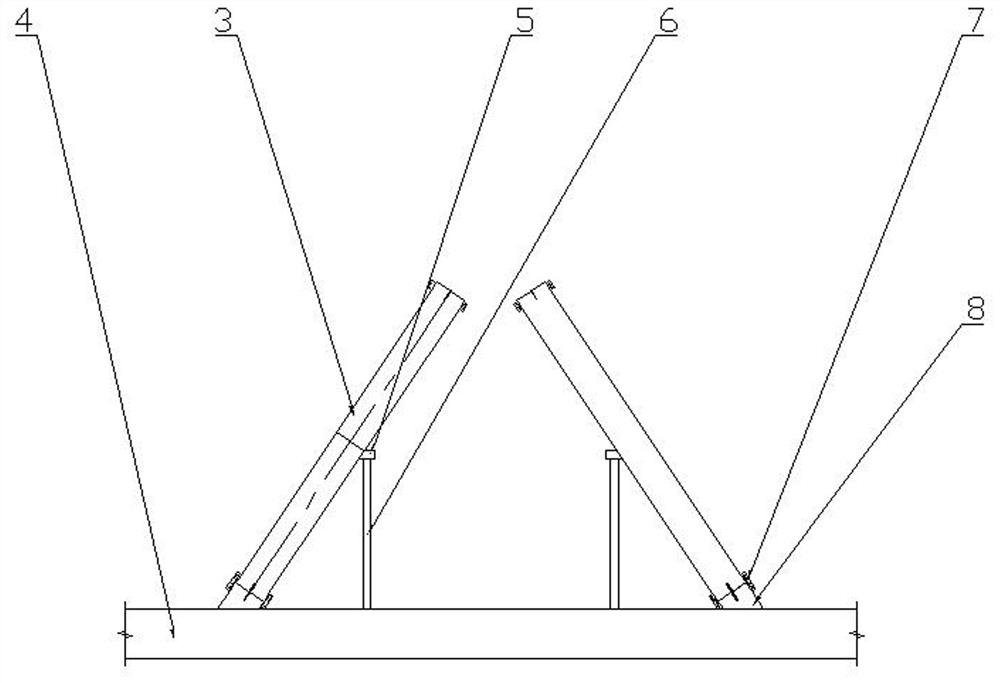

[0027] Embodiment: As shown in the figure, a method for installing an outer frame cylinder structure of oblique steel pipe grid columns includes the following steps:

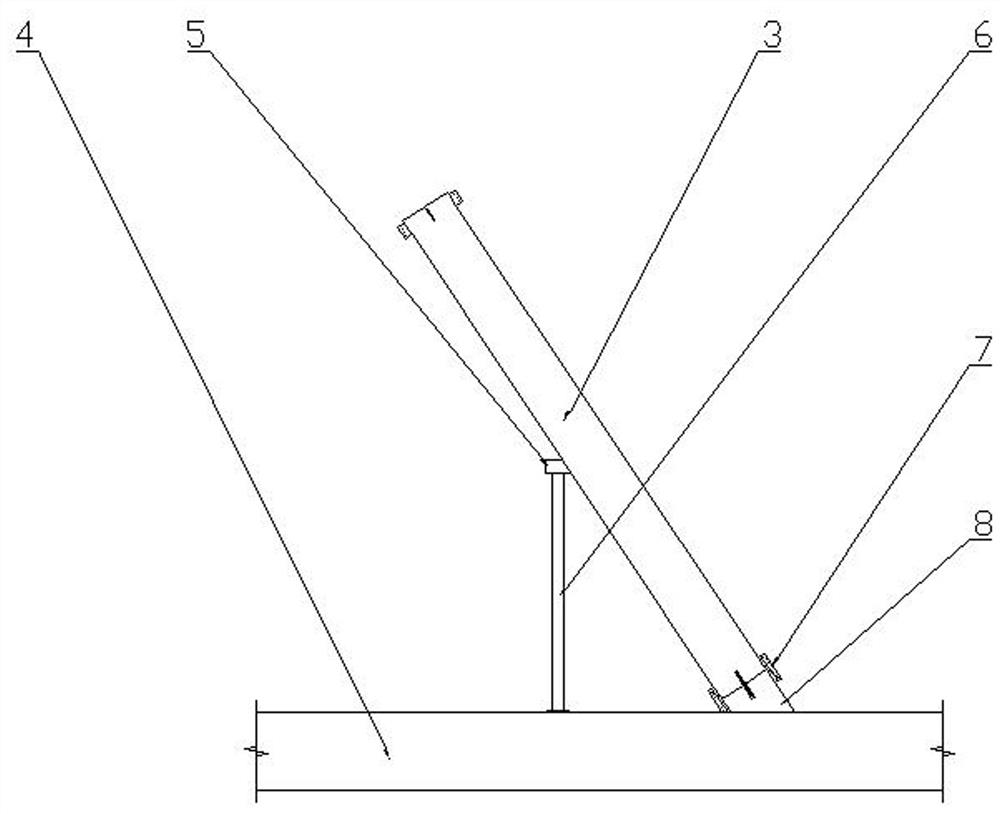

[0028] Step 1: Position the supporting steel pipe 8 on the base 4, and complete the welding and fixing process of the supporting steel pipe 8 and the base 4 according to the installation slope and span of the grid column 3.

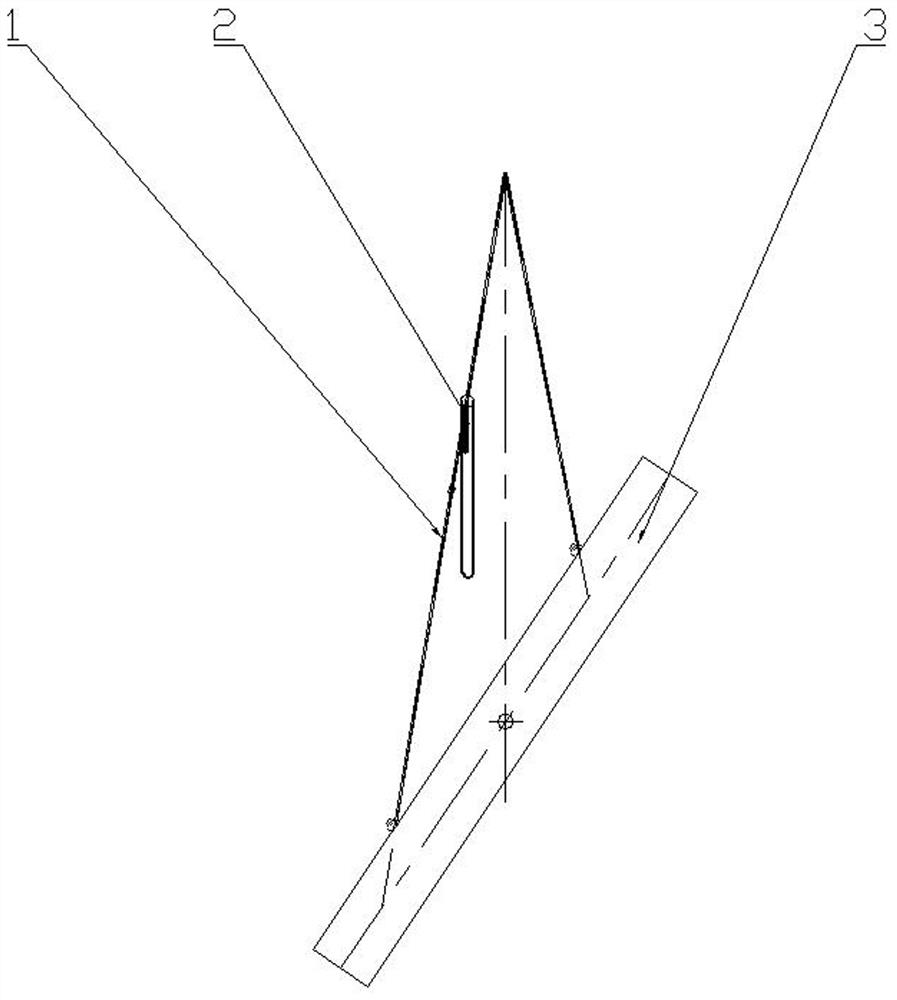

[0029] The second step: then adjust the angle inclination of the sling 1 through the chain hoist 2 to align the hoisting process of the grid column 3 . The length of the sling 1 , the position of the hanging point and the angle are determined by the installation length, angle and center of gravity position of the grid post 3 . The connecting length between the sling 1 and the lower part of the grid column 3 is 12 meters, and the connecting length between the sling 1 and the upper part of the grid column 3 is 7 meters.

[0030] Step 3: After the grid column 3 is aligned with the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com