Automatic protection safety elevator

An automatic protection and elevator technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of high labor intensity, affecting construction safety, and potential safety hazards, saving labor costs, reducing accident rates, The effect of saving work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

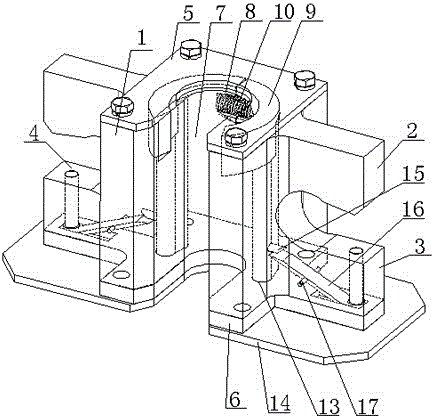

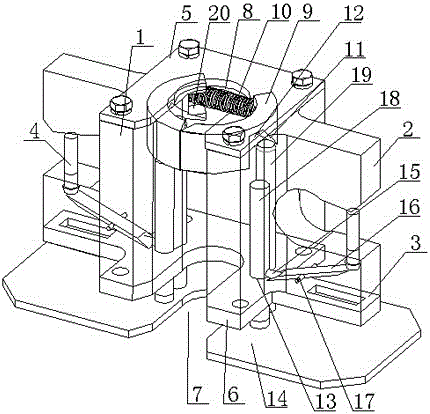

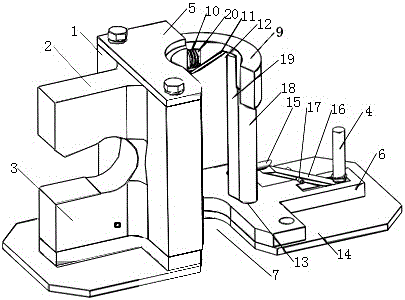

[0015] refer to Figure 1-Figure 3 , the automatic protection safety elevator, including the elevator body 1, the left and right sides of the elevator body 1 are respectively provided with lifting lugs, the lifting lugs are detachably connected with the lifting rings, the lifting lugs include the upper lifting lug 2 and the lower lifting lug 3, and the lower lifting lugs Ears 3 are movable to be provided with ring lock pins 4 for preventing the rings from coming off.

[0016] On the upper end surface and the lower end surface of the elevator body 1, the elevator upper cover plate 5 and the elevator lower cover plate 6 are respectively fixedly installed, and the elevator upper cover plate 5 is fixed on the elevator body 1 by fastening bolts and spring washers. of the upper end. The valve 9 can be positioned in the annular groove 8 through the elevator upper cover plate 5, and the up and down movement of the valve 9 and the spring 10 is restricted.

[0017] The upper elevator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com