Beveled container nozzle forming auxiliary device and beveled container nozzle forming device

An auxiliary device and container technology, which is applied in glass forming, glass re-molding, glass manufacturing equipment, etc., can solve the problems of not easy to fix to the support base, difficult to pinch the mouth and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

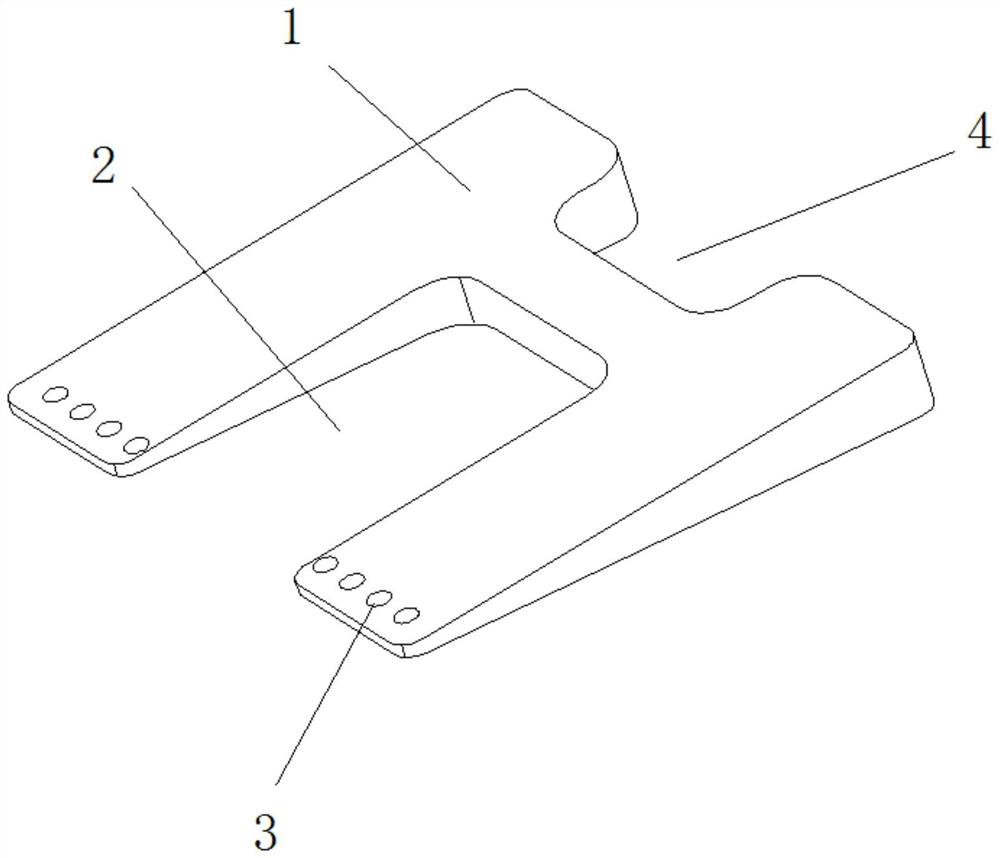

[0022] Embodiment 1, the present invention provides an auxiliary device for forming the mouth of a beveled container, see figure 1 , including a supporting plate 1, the supporting plate described here is a plate used to hold the obliquely cut container at the bottom, the thickness of one end of the supporting plate is greater than the thickness of the other end, so that an inclination is formed between the upper and lower sides of the supporting plate Angle; the supporting plate is provided with a first notch 2 at the end with a smaller thickness, which is used for the pinch wheel of the pinch mouth molding mechanism to pass through, and the two sides of the first notch are provided with positioning holes 3, and the positioning holes can generally be Made into threaded holes.

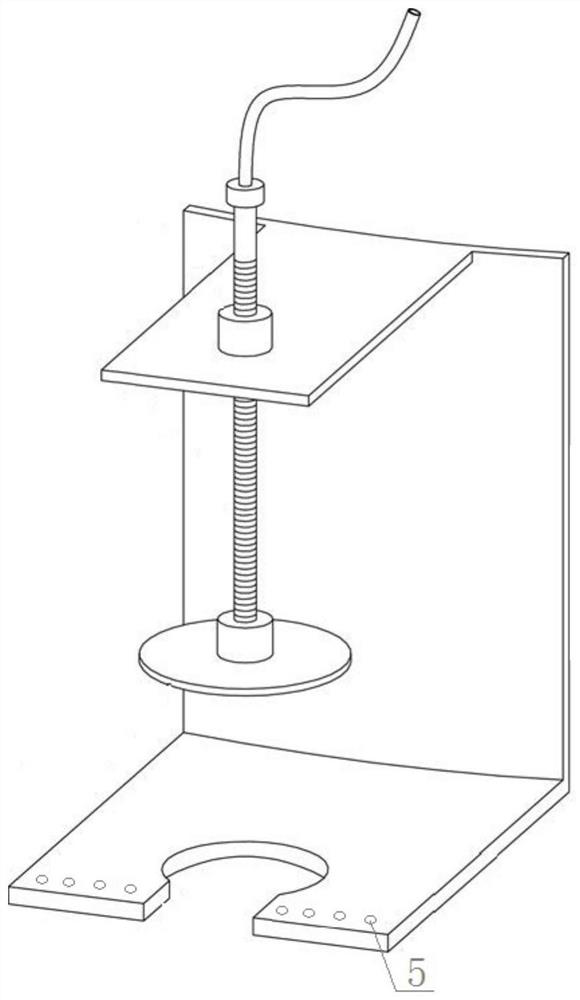

[0023] The mouth shape auxiliary device for oblique containers can be used in conjunction with the existing mouth pinching machine equipment. Specifically, it is fixed on the support base, and the suppo...

Embodiment 2

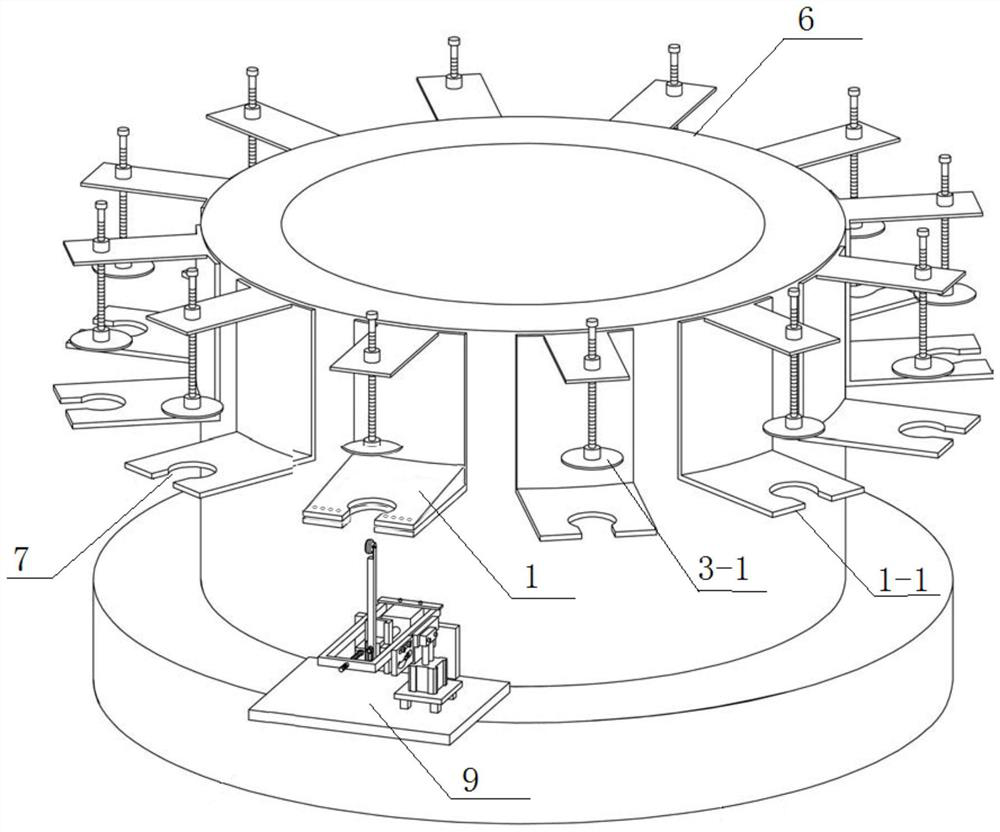

[0027] Embodiment 2, the present invention provides a kind of bevel container nozzle forming device, see image 3 , including the above-mentioned auxiliary device for forming the beveled container mouth, a spring pressure plate 3-1 that can move up and down, a support base 1-1, a pinching mouth molding mechanism 9, and a rotary table 6; the support base is connected to the rotary table ; The spring pressing plate is set on the rotary table above the support base, the pinch molding mechanism is located below the support base; Above: a third notch 7 is provided on the support base corresponding to the first notch, this structure can combine the above-mentioned slanted container mouth forming auxiliary device with the existing slanted container mouth forming device to form a new slanted container The mouth forming device can directly carry out the mouth pulling operation on the beveled container. When the worktable rotates, the fixed glass container becomes soft under the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com