Safe concentration process and system for sodium nitrophenolate wastewater

A technology of sodium nitrophenolate and concentration system, which is applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc. Efficient and safe concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

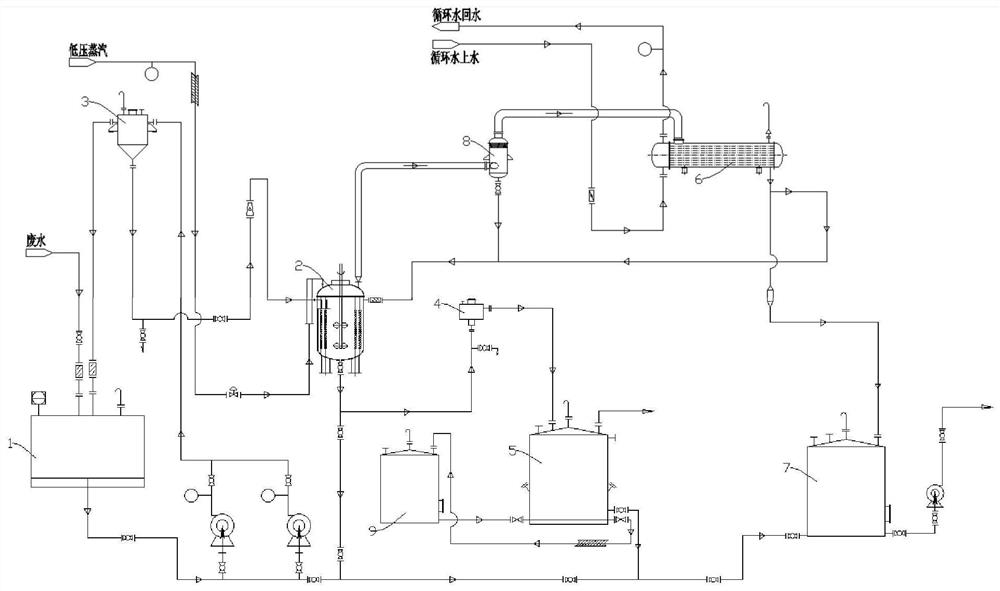

[0031] The safe concentration process of nitrophenol sodium salt wastewater comprises the following steps:

[0032] A1: Concentrate the sodium phenate waste water with 30% of the raw water in a vacuum with the residual steam of the factory building to obtain the pre-concentrated sodium phenate waste water, and transport the pre-concentrated sodium phenate waste water to the waste water pool for storage;

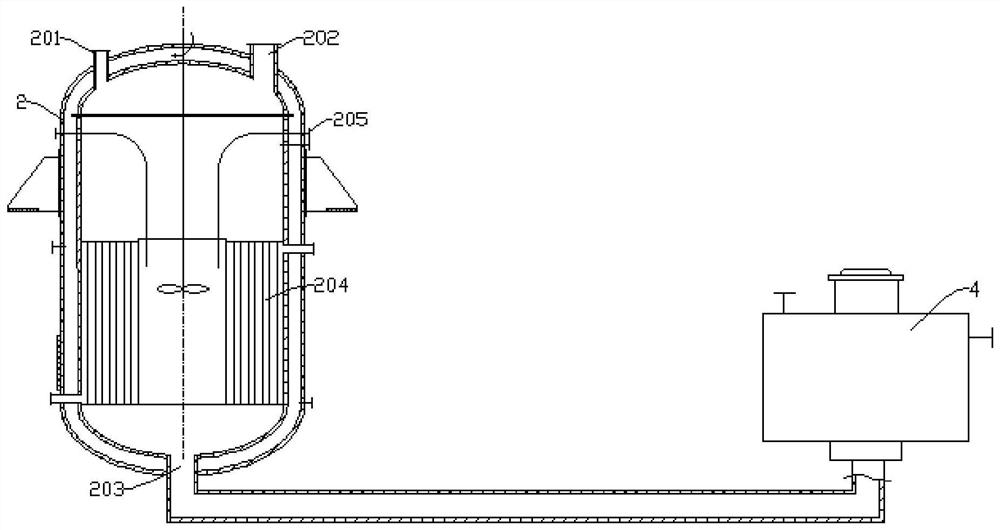

[0033] A2: The pre-concentrated sodium phenate wastewater is transported to the waste water transfer tank 1, and pumped from the waste water transfer tank 1 to the waste water high tank 3, and the pre-concentrated sodium phenate waste water in the waste water high tank 3 is measured and stabilized by a flow meter Conveying into the concentration tank 2 for concentration, controlling the flow rate of the pre-concentrated sodium phenate wastewater into the concentration tank 2 to be 2t / h; the temperature in the concentration tank 2 is set to 107°C; , the height of the liquid le...

Embodiment 2

[0045] The safe concentration process of nitrophenol sodium salt wastewater comprises the following steps:

[0046] A1: Concentrate the sodium phenate waste water with 40% of the raw water in a vacuum with the residual steam of the factory building to obtain the pre-concentrated sodium phenate waste water, and transport the pre-concentrated sodium phenate waste water to the waste water pool for storage;

[0047] A2: The pre-concentrated sodium phenate wastewater is transported to the waste water transfer tank 1, and pumped from the waste water transfer tank 1 to the waste water high tank 3, and the pre-concentrated sodium phenate waste water in the waste water high tank 3 is measured and stabilized by a flow meter Conveying into the concentration kettle 2 for concentration, controlling the flow rate of the pre-concentrated sodium phenate wastewater into the concentration kettle 2 to 2.5t / h; In the overflow box 4, the liquid level in the overflow box 4 is always kept the same a...

Embodiment 3

[0050] The safe concentration process of nitrophenol sodium salt wastewater comprises the following steps:

[0051] A1: Concentrate the sodium phenate waste water with 35% of the raw water in a vacuum with the residual steam of the factory building to obtain the pre-concentrated sodium phenate waste water, and transport the pre-concentrated sodium phenate waste water to the waste water pool for storage;

[0052] A2: The pre-concentrated sodium phenate wastewater is transported to the waste water transfer tank 1, and pumped from the waste water transfer tank 1 to the waste water high tank 3, and the pre-concentrated sodium phenate waste water in the waste water high tank 3 is measured and stabilized by a flow meter Conveying into the concentration kettle 2 for concentration, controlling the flow rate of the pre-concentrated sodium phenate wastewater into the concentration kettle 2 to be 2.3t / h; the temperature in the concentration kettle 2 is set to 80°C; In the overflow box 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com