Vertical type paint spraying equipment

A kind of painting equipment and vertical technology, applied in the field of painting, can solve the problems of inconvenient movement, etc., and achieve the effects of weight reduction, good safety and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

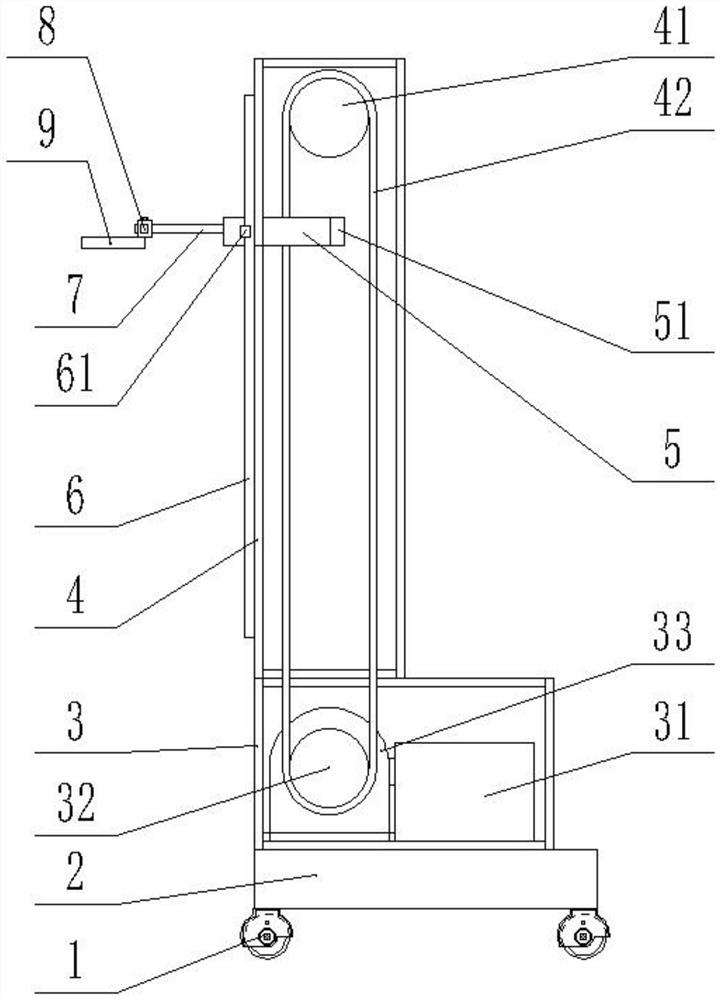

[0022] see Figure 1-4 , a vertical painting equipment, including a caster structure 1, a mobile base 2, a vertical support 4 and a spray gun 9,

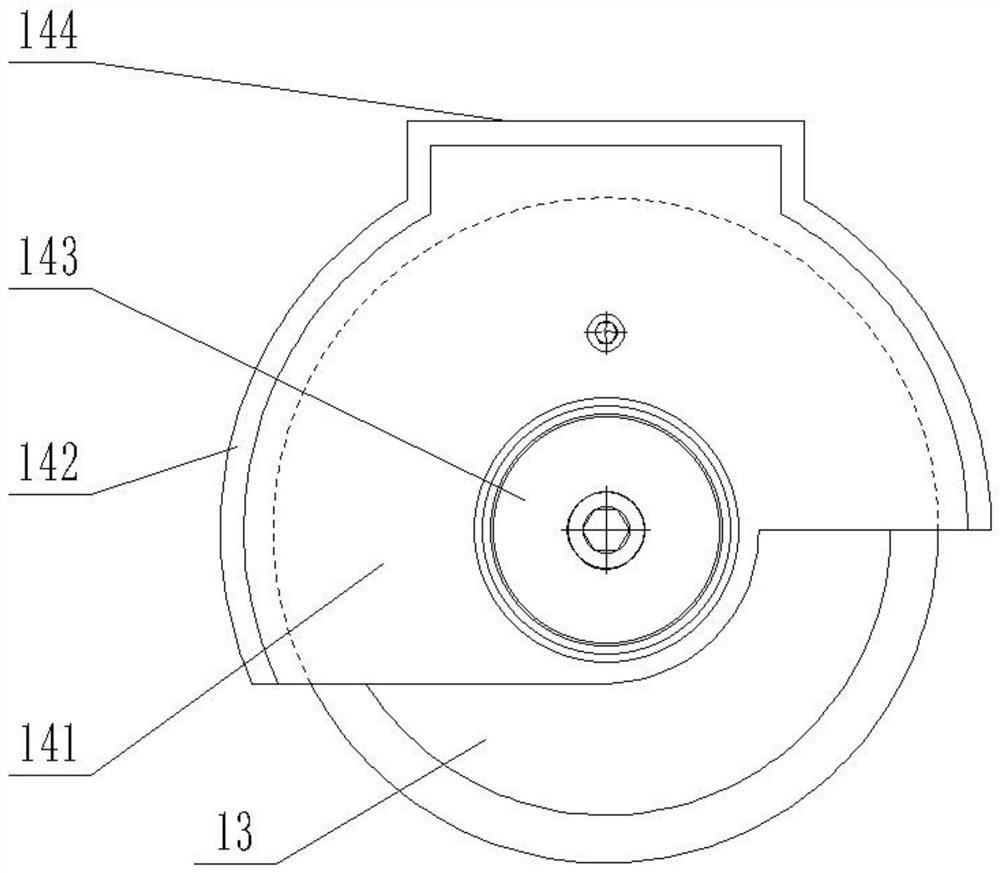

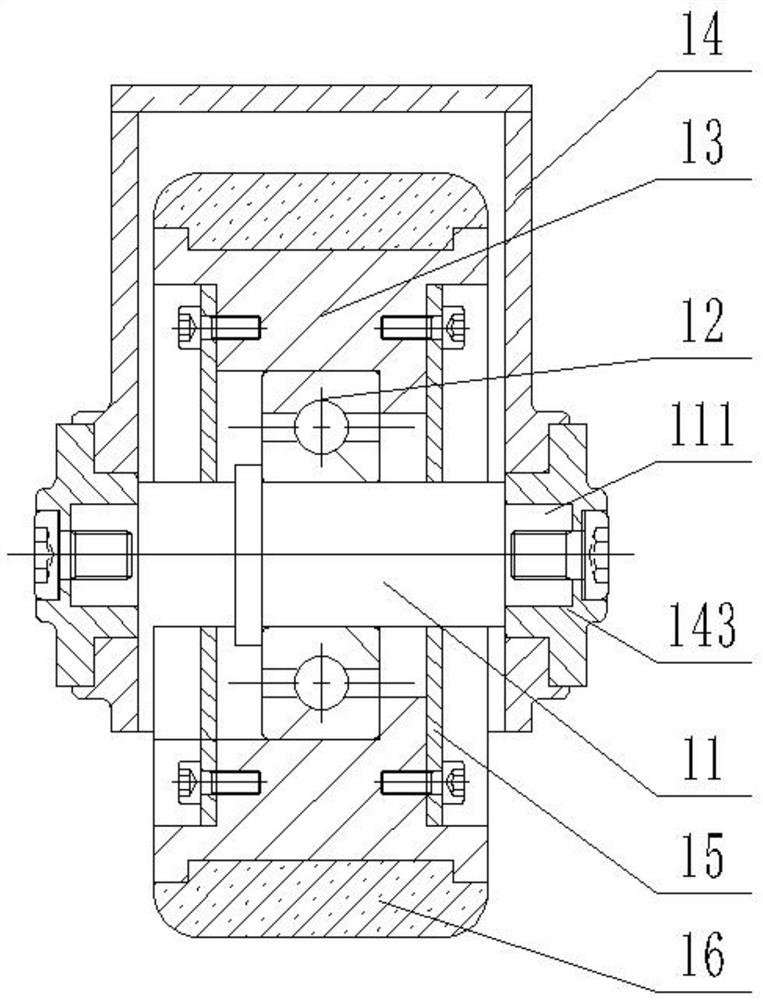

[0023] The four corners of the bottom of the mobile base 2 are provided with a caster structure 1. Because the stability of the one-way wheel is relatively good, the caster structure 1 adopts a one-way wheel. The caster structure 1 includes a wheel shaft 11, a radial ball bearing 12 , the wheel hub 13 and the wheel frame 14, the radial ball bearing 12 is fixedly sleeved on the said wheel shaft 11, the wheel hub 13 is fixed on the radial ball bearing 12, and the tire 16 of rubber material is fixedly sleeved on the wheel hub 13; the wheel shaft 11 Both ends are fixed with the wheel frame 14 by screws;

[0024] The wheel frame 14 includes a tire protection structure 142 and an axle support structure 141 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com