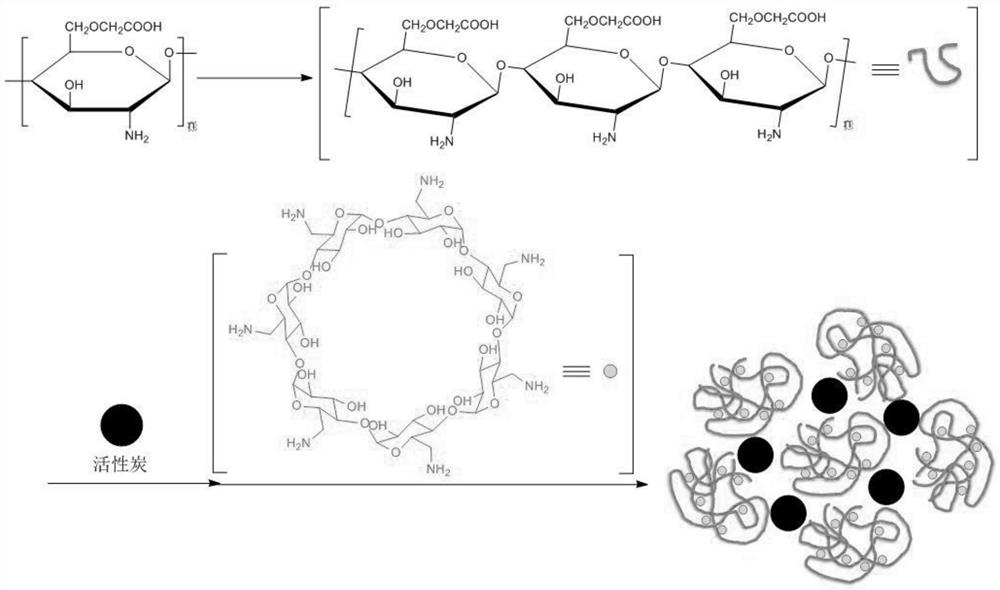

Carboxymethyl chitosan-cyclodextrin-activated carbon composite material and application thereof

A technology of carboxymethyl chitosan and composite materials, applied in the directions of alkali metal compounds, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of solid waste pollution, high operating costs, short service life, etc. , to achieve the effect of low purification cost, convenient operation and excellent water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

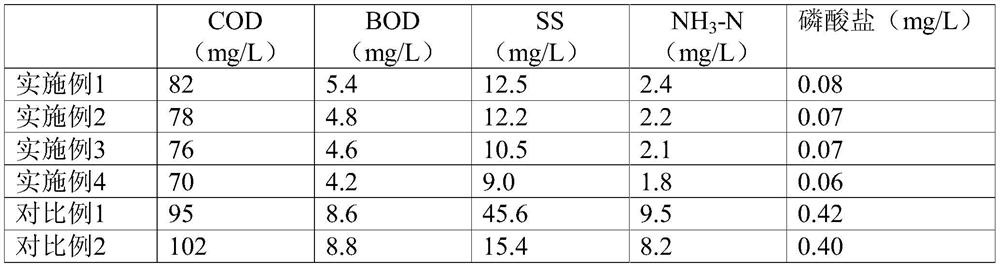

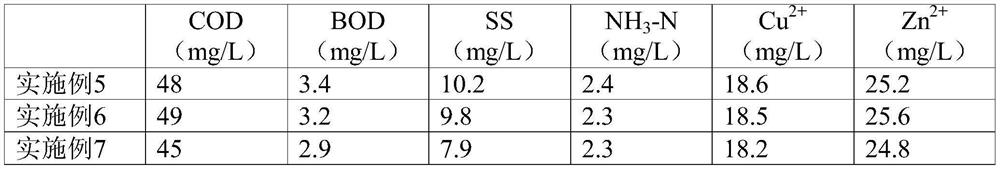

Examples

Embodiment 1

[0037] A carboxymethyl chitosan-cyclodextrin-activated carbon composite material is prepared according to the following steps:

[0038] ① Preparation of carboxymethyl chitosan:

[0039] Add chitosan to isopropanol, continue stirring for 30-60 minutes, add sodium hydroxide, control the temperature of the reaction solution at 35°C during the addition process, stop adding sodium hydroxide when the pH value of the reaction solution is 8.5, Continue to stir for 30 minutes, then dropwise add chloroacetic acid isopropanol solution, control the temperature of the reaction solution below 45°C during the dropwise addition, raise the temperature to 50°C after the dropwise addition, stir and react for 6 hours, add the first ethanol precipitation, filter, filter The cake is washed with second ethanol and dried to obtain carboxymethyl chitosan;

[0040] The mass concentration of chloroacetic acid in the chloroacetic acid isopropanol solution is 8%;

[0041] Wherein the mass ratio of chito...

Embodiment 2

[0047] A carboxymethyl chitosan-cyclodextrin-activated carbon composite material is prepared according to the following steps:

[0048] ① Preparation of carboxymethyl chitosan:

[0049] Add chitosan to isopropanol, continue stirring for 60 minutes, add sodium hydroxide, control the temperature of the reaction solution at 45°C during the addition process, stop adding sodium hydroxide when the pH value of the reaction solution is between 9.0, Continue to stir for 60 minutes, then dropwise add chloroacetic acid isopropanol solution, control the temperature of the reaction solution below 45°C during the dropwise addition, raise the temperature to 55°C after the dropwise addition, stir and react for 6 hours, add the first ethanol precipitation, filter, filter The cake is washed with second ethanol and dried to obtain carboxymethyl chitosan;

[0050] The mass concentration of chloroacetic acid in the chloroacetic acid isopropanol solution is 12%;

[0051] Wherein the mass ratio of...

Embodiment 3

[0057] A carboxymethyl chitosan-cyclodextrin-activated carbon composite material is prepared according to the following steps:

[0058] ① Preparation of carboxymethyl chitosan:

[0059] Add chitosan to isopropanol, continue to stir for 50 minutes, add sodium hydroxide, control the temperature of the reaction solution at 40°C during the addition process, stop adding hydroxide when the pH value of the reaction solution is between 8.5 and 9.0 Sodium, continue to stir for 45 minutes, then dropwise add chloroacetic acid isopropanol solution, control the temperature of the reaction solution below 45°C during the dropwise addition, raise the temperature to 50-55°C after the dropwise addition, stir for 6 hours, add the first ethanol to precipitate , filtered, the filter cake was washed with second ethanol, and dried to obtain carboxymethyl chitosan;

[0060] The mass concentration of chloroacetic acid in the chloroacetic acid isopropanol solution is 9%;

[0061] Wherein the mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com