Single-crystal ternary positive electrode material and preparation method and application thereof

A positive electrode material and single crystal technology, applied in the field of single crystal ternary positive electrode materials and its preparation, can solve the problem of increasing the specific surface area of single crystal ternary positive electrode materials, accelerating capacity fading and surface side reactions, and phase change of the surface structure of positive electrode materials, etc. problems, to achieve the effects of improving electrochemical performance and structural stability, increasing electronic/ionic conductivity, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of the single crystal ternary cathode material of this embodiment comprises the following steps:

[0046] 1) The hydroxide precursor Ni 5 co 2 mn 3 (OH) 2 With lithium carbonate, Al 2 o 3 and WO 2 Mixing (the molar ratio of lithium carbonate and the hydroxide precursor is 1.07:1.0, and the contents of Al and W are 1500ppm and 2000ppm respectively) to obtain a mixed material;

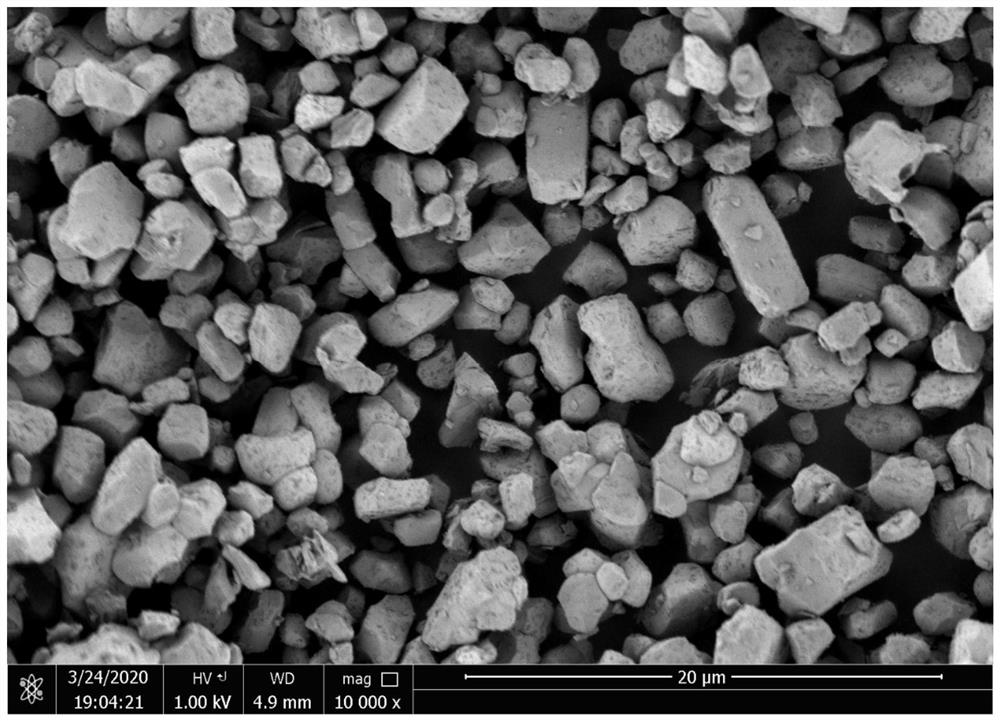

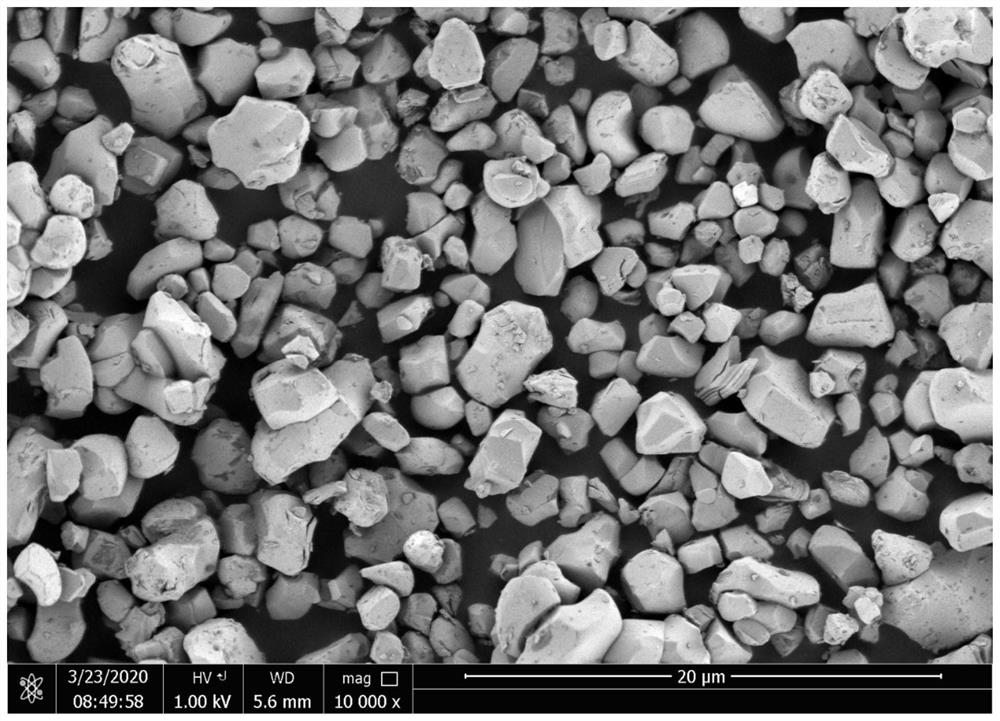

[0047] 2) Carry out the first sintering of the mixed materials, each saggar has a charging volume of 4.0kg and an air flow rate of 8m 3 / h, first raise the temperature to 750°C, hold for 5.0h, continue to heat up to 930°C for sintering, hold for 8h, and finally cool down to 30°C, the heating and cooling rate is 2°C / min, and then the single crystal with a D50 of 3.6μm is obtained by jet crushing MaterialLiNi 0.498 co 0.2 mn 0.3 m 0.002 o 2 , the morphology before and after crushing is as follows figure 1 shown;

[0048] 3) Combining single crystal material with ...

Embodiment 2

[0059] The preparation method of the single crystal ternary cathode material of this embodiment comprises the following steps:

[0060] 1) The hydroxide precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 With lithium hydroxide, B 2 o 3 and Al 2 o 3 Mixing (the molar ratio of lithium hydroxide to the precursor is 1.02:1.0, and the contents of B and Al are 800ppm and 2000ppm respectively) to obtain a mixed material;

[0061] 2) Carry out the first sintering of the mixed materials, each saggar has a charging volume of 4.0kg and an air flow rate of 8m 3 / h, first raise the temperature to 750°C, hold for 5.0h, continue to heat up to 930°C for sintering, hold for 8h, and finally cool down to 30°C, the heating and cooling rate is 2°C / min, and then get a single crystal with a D50 of 3.6μm through jet crushing The material, the morphology before and after crushing are as follows: figure 1 shown;

[0062] 3) Combine the single crystal material with H 3 BO 3 Mix (the content of ion B is 1...

Embodiment 3

[0066] A method for preparing a single crystal ternary positive electrode material, comprising the steps of:

[0067] (1) The precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 With lithium hydroxide, Y 2 o 3 and TiO 2 Mixing (the molar ratio of lithium hydroxide to the precursor is 1.05:1.0, and the contents of Y and Ti are 1500ppm and 2000ppm respectively) to obtain a mixed material;

[0068] (2) Carry out the first sintering of the mixed materials, each saggar is filled with 5.0kg, and the air flow is 8m 3 / h, heat up to 700°C, hold for 5.0h, continue to heat up to 930°C for sintering, hold for 9h, and finally cool down to 30°C, the temperature rise and fall rate is 3°C / min, and then the single particle material with D50 of 3.6μm is obtained through jet milling ;

[0069] (3) Combine the single particle material with LiH 2 PO 4 and Li 3 PO 4 mixed (the content of ion B is 1200ppm), to obtain LiH 2 PO 4 and Li 3 PO 4 Co-coated cathode materials;

[0070] (4) 8m into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com