Low-cycle fatigue life prediction method based on high-temperature alloy machining surface integrity

A technology for fatigue life prediction and high-temperature alloys, which is applied in the direction of applying repetitive force/pulsation force to test material strength, measuring devices, and strength characteristics, etc., which can solve the problems affecting the accuracy of fatigue life prediction, cumbersome derivation process, and the size of grains on the surface of parts Influence and other issues, to achieve the effect of broad scientific research value and engineering application prospects, avoid duplication of experiments and data collection, save time and material expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

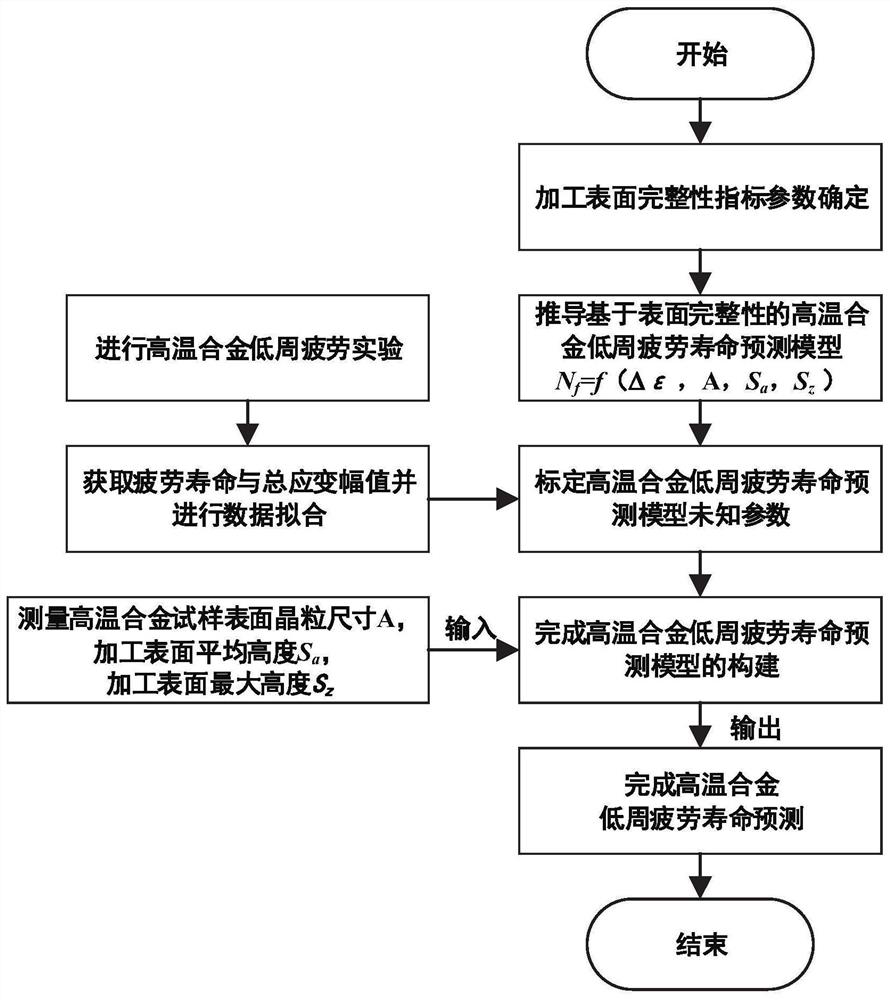

[0049] The present invention is a method for predicting the low-cycle fatigue life of a high-temperature alloy sample based on the integrity of the machined surface. Taking the turned sample of GH4169 nickel-based superalloy as an example, the specific implementation steps of the low-cycle fatigue prediction method under high-temperature conditions are introduced in detail:

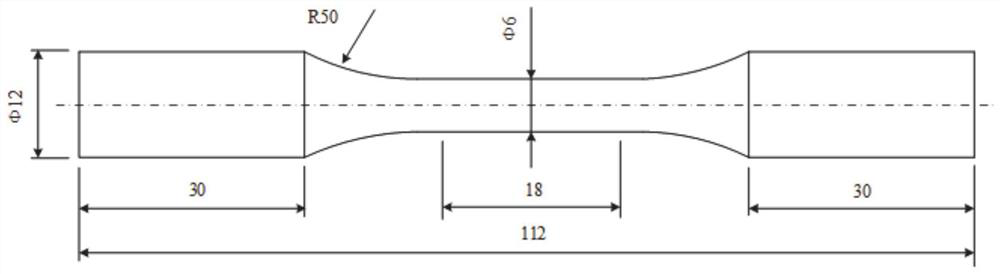

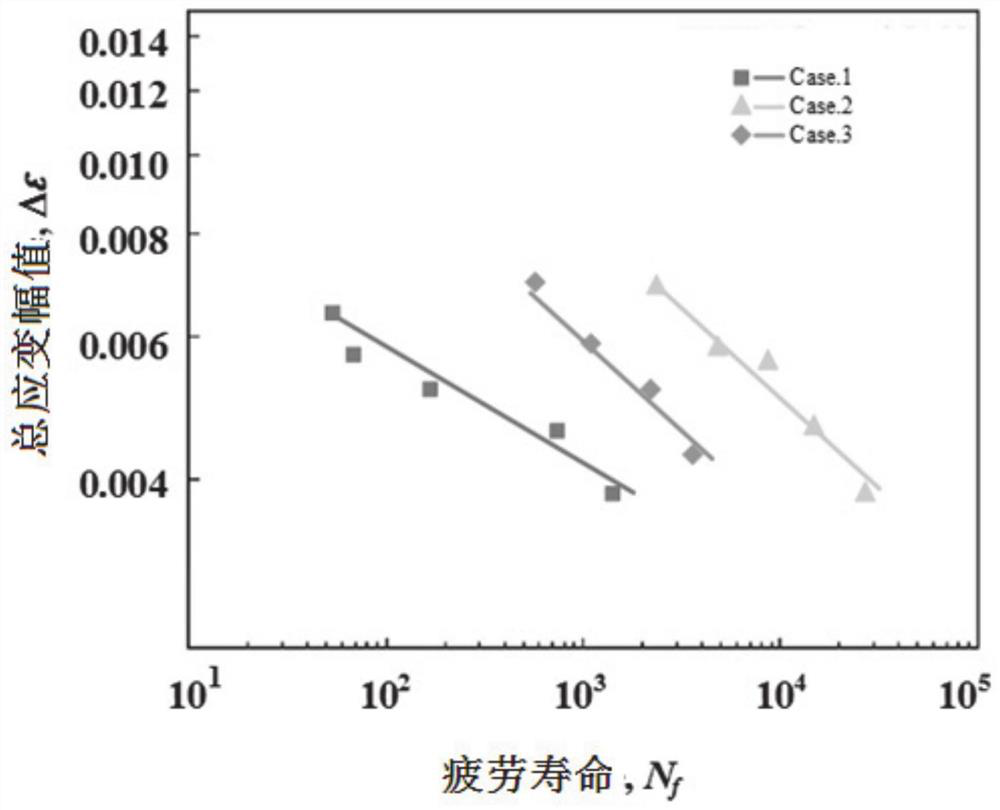

[0050] S1. The low-cycle fatigue test of GH4169 nickel-based superalloy at a constant temperature of 650°C was carried out using a servo hydraulic fatigue testing machine. The total axial strain was controlled between 0.2% and 0.6%, the strain ratio was -1, and the loading frequency was 20Hz. , the sample size as figure 2 shown. Obtain the data of fatigue life and total strain amplitude, and plot the relationship between fatigue life and total strain amplitude in the double logarithmic coordinate system image 3 .

[0051] S2. Select the sample for the fatigue test, cut it perpendicular to the sample i...

Embodiment 2

[0062] The invention is a low-cycle fatigue life prediction method for high-temperature alloy samples based on the integrity of the processed surface. Taking the GH4169 nickel-based high-temperature alloy finish turning-rolling combination processing sample as an example, the low-cycle fatigue prediction method under normal temperature conditions is introduced in detail. The implementation steps:

[0063] S1. The low-cycle fatigue test of the GH4169 nickel-based superalloy finish turning-rolling combination processing sample was carried out under normal temperature conditions using a servo hydraulic fatigue testing machine. The total axial strain was controlled between 0.2% and 0.6%, and the strain ratio was 0.1. The loading frequency is 90Hz, and the sample size is as follows figure 2 shown. Obtain the data of fatigue life and total strain amplitude, and plot the relationship between fatigue life and total strain amplitude in the double logarithmic coordinate system image...

Embodiment 3

[0075] The invention is a method for predicting the low-cycle fatigue life of a high-temperature alloy sample based on the integrity of the processed surface, but it also has guiding significance for the prediction of the low-cycle fatigue life of other alloy samples. Taking the TC4 high-temperature titanium alloy finish turning-rolling combination processing sample as an example, the specific implementation steps of the low cycle fatigue prediction method under normal temperature conditions are introduced in detail:

[0076] S1. The low-cycle fatigue test of the TC4 titanium alloy finish turning-rolling combined processing sample was carried out under normal temperature using a servo hydraulic fatigue testing machine. The total axial strain was controlled between 0.4% and 0.8%, and the strain ratio was 0.481. Frequency is 0.5Hz, fatigue limit σ -1 407Mpa, tensile strength σ b is 974Mpa, the sample size is as figure 2 shown. Obtain the data of fatigue life and total strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com