Optical fiber vibration measurement device and method with improved light source noise

A fiber optic vibration and measurement device technology, which is applied to the measurement device, uses optical devices to transmit sensing components, and measures ultrasonic/sonic/infrasonic waves. Measurement accuracy, improvement of measurement accuracy, and effect of avoiding frequency drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

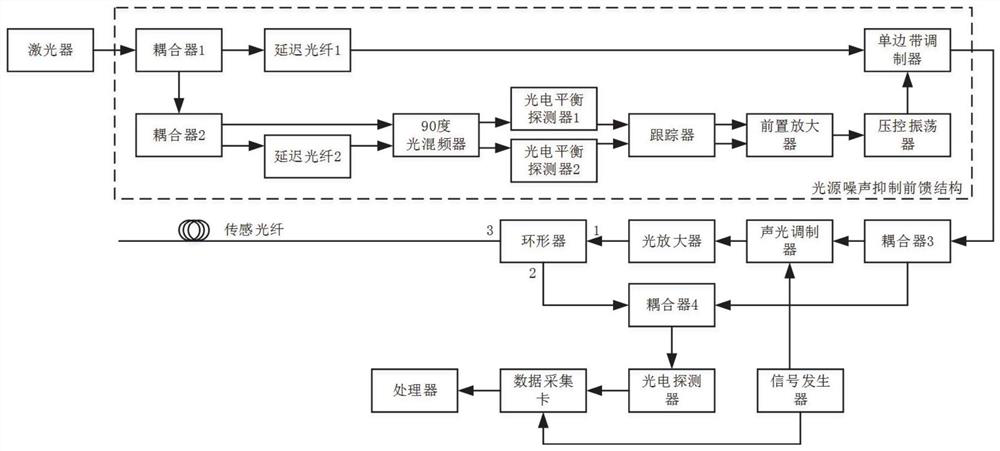

[0049] A typical embodiment of the present disclosure, as Figure 1 - Figure 2 , The proposed improved optical noise source a vibration measuring device.

[0050] Which apparatus comprising: a laser light source feedforward noise suppressing structure, the coupler 3, the acousto-optic modulator, erbium doped fiber amplifier, a circulator, a sensing fiber, coupler 4, a photodetector, a data acquisition card, and a signal generator processor.

[0051] After exiting the laser linewidth narrower continuous light source through a feedforward noise suppressing structure, entering through the power coupler having a specific ratio 3, is divided into two, wherein all the way through the continuous light having the acousto-optic modulator frequency shift function, having converted to light having a specific width and pulse period, and then after the optical amplifier power compensator into the annular port 1, and then emitted through the annular port to the sensing fiber 3, acquired carrying...

Embodiment 2

[0063] Another exemplary embodiment of the present disclosure, as Figure 1 - Figure 2 , The proposed method for the optical fiber vibration measurement noise source improved.

[0064] Step 1, a continuous laser output wavelength of 1330nm or 1550nm light:

[0065]

[0066] Wherein, A represents the amplitude of the light wave, v 0 Representative light wave frequency, constant 193.5THz (corresponding to the wavelength of 1550nm) or 229.0THz (corresponding to the wavelength of 1310nm), θ (t) representative of the phase noise light, t represents time.

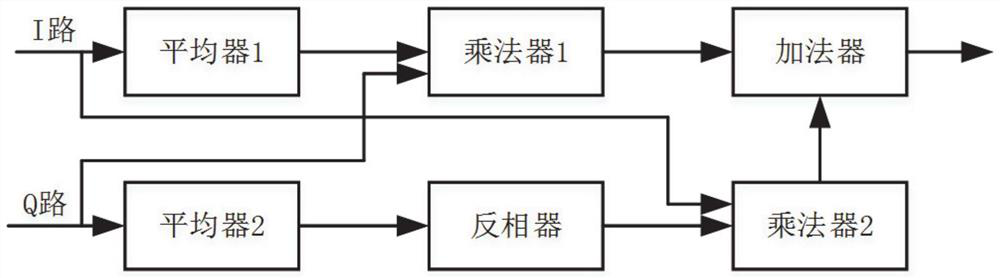

[0067] Step 2, a continuous laser light into two paths, wherein a channel using classical Mach - Zehnder interferometer, to give two (I and Q-) orthogonal interference signal:

[0068] I (t) = B cos (2πν 0 τ + Δθ (t)) (2)

[0069] Q (t) = B sin (2πν 0 τ + Δθ (t)) (3)

[0070] Δθ (t) = θ (t) -θ (t-τ) (4)

[0071] Wherein, B represents an interference signal amplitude, Δθ (t) represents a first order source phase noise difference, τ r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com