A composite durable antistatic non-bitumen-based self-adhesive gas isolation board and its preparation method

A non-asphalt-based, antistatic technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of size change, gas leakage, etc., and achieve the advantages of improving strength, prolonging the life of the sheet, and increasing the weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

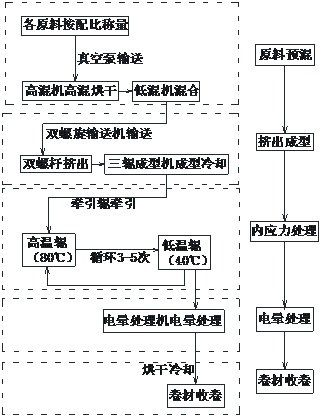

[0128] S1. Preparation of polymer waterproof board:

[0129] ①Raw materials, as shown in Table 1 below:

[0130] Table 1 embodiment 1 prepares the raw material that polymer waterproof board adopts

[0131]

[0132] ②Preparation method:

[0133] A1. Raw material premixing: Inhale all raw materials into the high-mixer through the vacuum pump according to the ratio, and dry them in the high-mixer at a temperature of 53°C, and the mixing time is 3 minutes, and then put them into the low-mixer for 5 minutes. , the raw materials are mixed evenly;

[0134] A2. Extrusion molding: The raw materials mixed uniformly in step A1 are transported into the twin-screw extruder through the twin-screw conveyor, and the polymer waterproof board is extruded through the extrusion temperature of 220°C-240°C, and then passed through three Cool to normal temperature after the roll forming machine is thickened and formed;

[0135]A3. Internal stress treatment: The polymer waterproof board formed...

Embodiment 2

[0154] S1. Preparation of polymer waterproof board:

[0155] ① Raw materials, as shown in Table 3 below:

[0156] Table 3 embodiment 2 prepares the raw material that polymer waterproof board adopts

[0157]

[0158] ②Preparation method:

[0159] A1. Raw material premixing: Inhale all the raw materials into the high mixer through the vacuum pump according to the ratio, and then dry them in the high mixer at a temperature of 50°C, and the mixing time is 2 minutes, and then put them into the low mixer for 6 minutes. , the raw materials are mixed evenly;

[0160] A2. Extrusion molding: The raw materials mixed uniformly in step A1 are transported into the twin-screw extruder through the twin-screw conveyor, and the polymer waterproof board is extruded through the extrusion temperature of 220°C-240°C, and then passed through three Cool to normal temperature after forming by roller forming machine to set thickness (2.0mm);

[0161] A3. Internal stress treatment: The polymer wa...

Embodiment 3

[0180] S1. Preparation of polymer waterproof board:

[0181] ① Raw materials, as shown in Table 5 below:

[0182] Table 5 embodiment 3 prepares the raw material that polymer waterproof board adopts

[0183]

[0184] ②Preparation method:

[0185] A1. Raw material premixing: Inhale all raw materials into the high-mixer through the vacuum pump according to the ratio, and dry them in the high-mixer at a temperature of 55°C, and the mixing time is 4 minutes, and then put them into the low-mixer for 4 minutes. , the raw materials are mixed evenly;

[0186] A2. Extrusion molding: The raw materials mixed uniformly in step A1 are transported into the twin-screw extruder through the twin-screw conveyor, and the polymer waterproof board is extruded through the extrusion temperature of 220°C-240°C, and then passed through three Cool to normal temperature after forming by roller forming machine to set thickness (2.0mm);

[0187] A3. Internal stress treatment: The polymer waterproof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

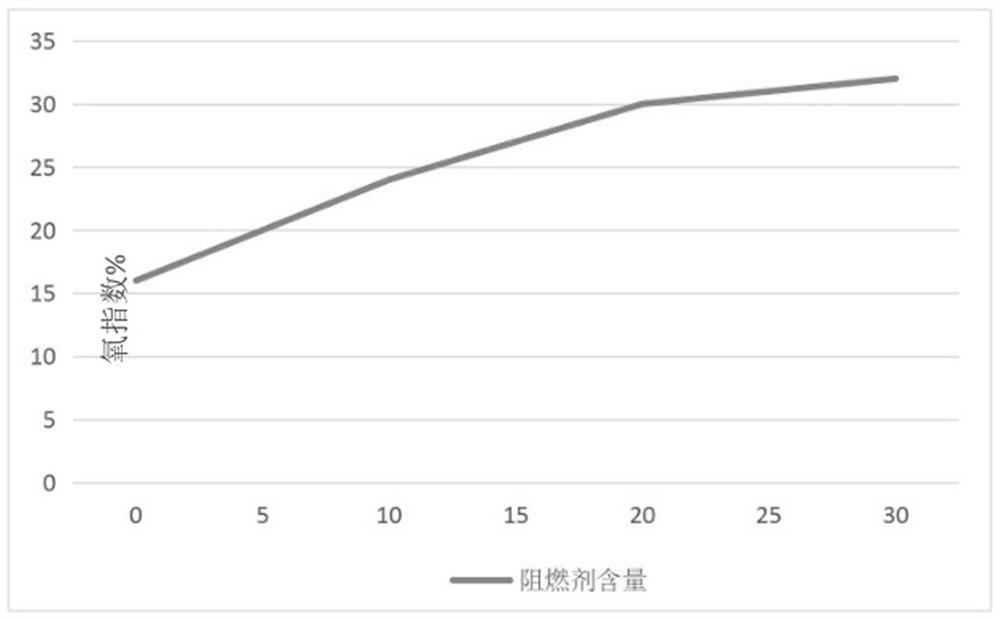

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com